High-speed multi-face code scanning and weighing detection system and method

A detection system and weighing technology, applied in logistics express intelligent scanning code, volume measurement, automatic sorting system, weighing field, can solve the problem of lack of detection equipment for volume measurement of goods, low degree of automation of goods sorting, and increased labor intensity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

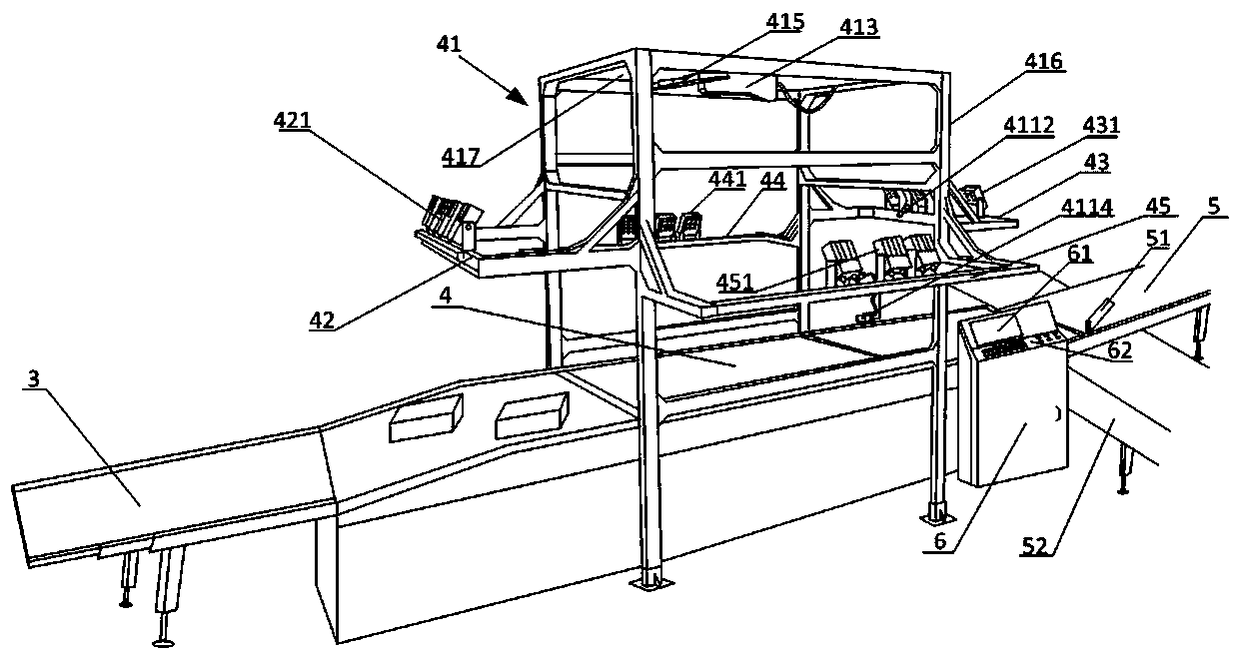

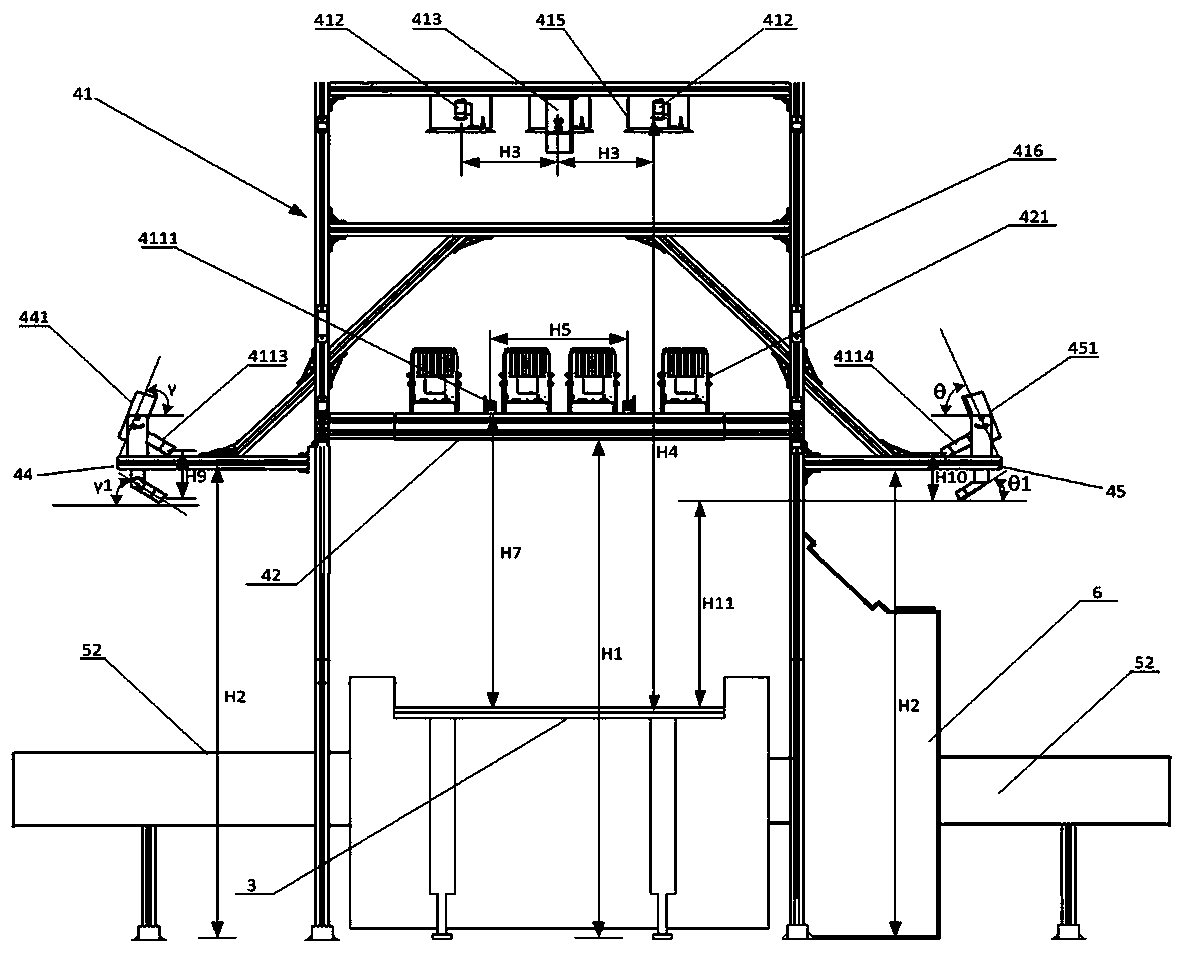

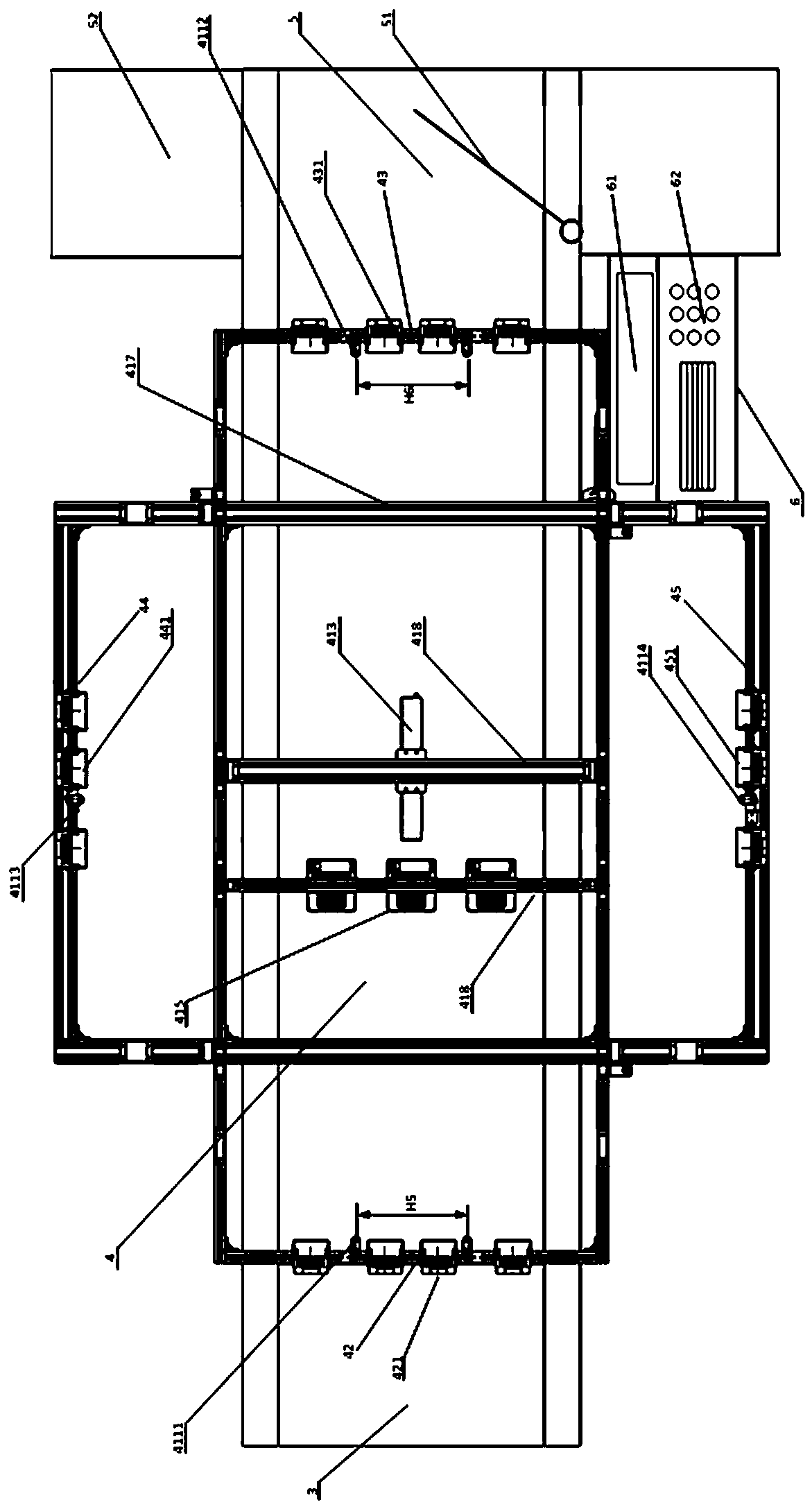

[0071] A high-speed multi-faceted code scanning and weighing detection system, such as Figure 1-Figure 5 As shown, it includes an express background server 1 and an express front server 2, the express background server is signal-connected to the express front server, and the express background server is used to enter and store the barcode, weight and mailing information of each express 3, The express foreground server is used to enter and store the barcode, weight and volume of each express; the express foreground server will store the barcode and the barcode stored by the express background server for information matching, once the barcode information matches successfully, it will trigger The background server of the express mail sends the slogan to the front server of the express mail;

[0072] It includes a conveying mechanism, which includes a telescopic section 4 for conveying the express from the truck, a weighing and scanning section 5 for detecting the weight of the e...

Embodiment 2

[0087] The invention also provides a high-speed multi-faceted code scanning and weighing detection method, such as Figure 6 shown, including the following steps:

[0088] S1. Express shipment loading and scanning. Before express shipment loading, use a scanner to scan the barcode attached to the express shipment to obtain the express shipment barcode information and send the express shipment barcode information to the express backend server, waiting for the express shipment barcode information to match;

[0089] S2. Express shipments are unloaded and transported. When the express mail is unloaded, put the express mail with the barcode on it and the barcode not facing down on the telescopic section, and the conveying mechanism will continuously transport the express mail;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com