Rapid self-operated mixing device and mixing method

A mixing device and self-operated technology, which is applied in the field of rapid self-operated mixing devices, can solve the problems of affecting the mixing ratio adjustment control of the water mixing system, affecting the mixing ratio adjustment of the system, and being unable to mix in time and fully, achieving low cost and fast mixing Uniform, length-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] This embodiment is a preferred solution.

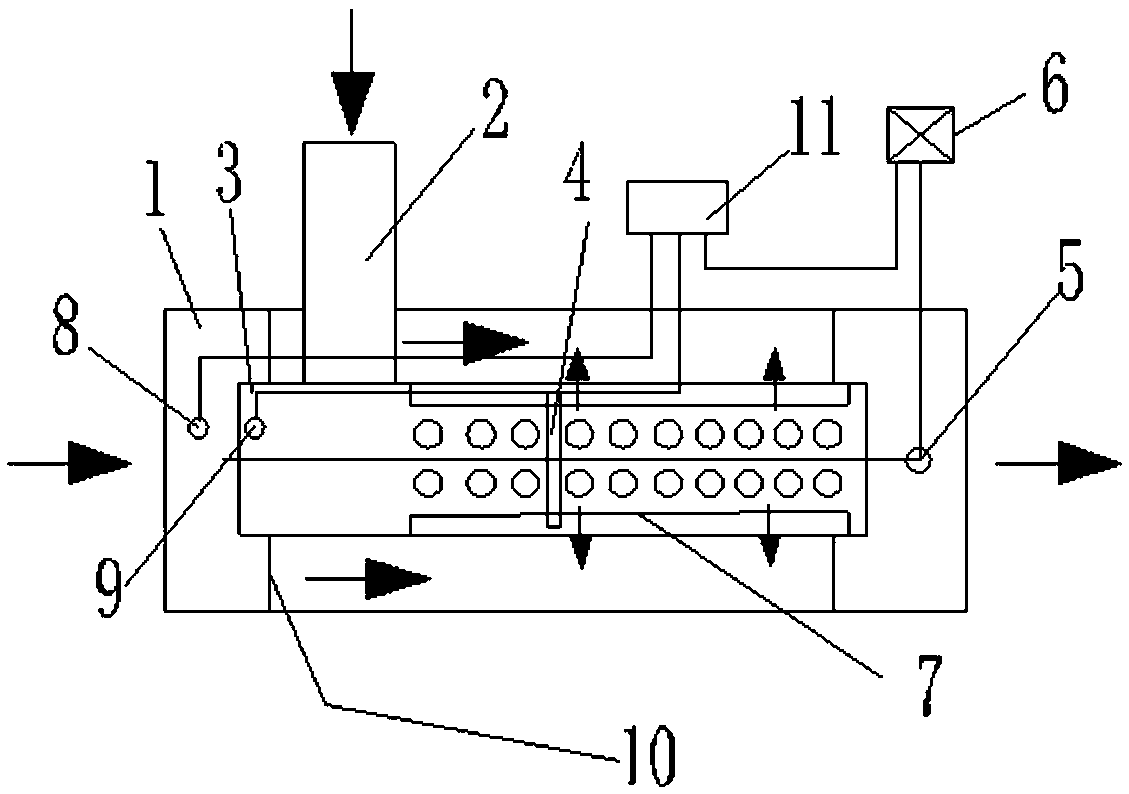

[0040] The structural representation of the fast self-operated mixing device of this embodiment can be found in figure 1 , which includes a first cylinder 1, a second cylinder 2, a third cylinder 3, a partition 4, a power transmission mechanism 5, a power device 6, a guide and limit mechanism 7, a first pressure sensor 8, a second pressure sensor Sensor 9 , structural support 10 and controller 11 . In this embodiment, the first cylinder 1 , the second cylinder 2 , and the third cylinder 3 are all cylindrical cylinders, and the first cylinder 1 has the largest diameter. The third cylinder 3 is installed coaxially inside the first cylinder 1 , and the third cylinder 3 is fixed by a structural support 10 . Obviously, the length of the first cylinder 1 is longer than that of the third cylinder 3 . Both ends of the first cylinder 1 are open, one end is the inlet of one fluid, and the other end is the outlet of the mixed fluid. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com