A new type of noodle belt conveying punching method

A new type of noodle belt technology, which is applied in dough forming and cutting combination, dough processing, dough forming machinery or equipment, etc. It can solve problems such as hidden troubles in the process of dough delivery and skin cutting, and achieve the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

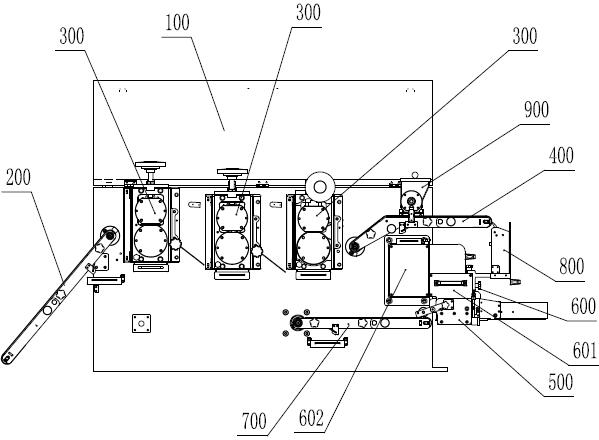

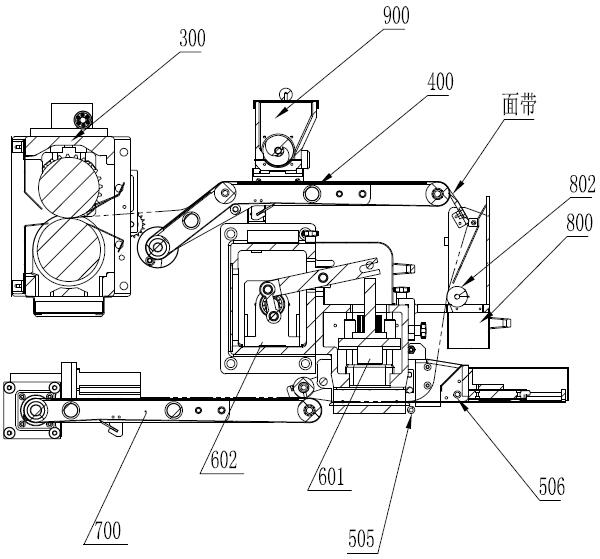

[0067] A novel noodle belt conveying punching method is characterized in that it comprises the following steps:

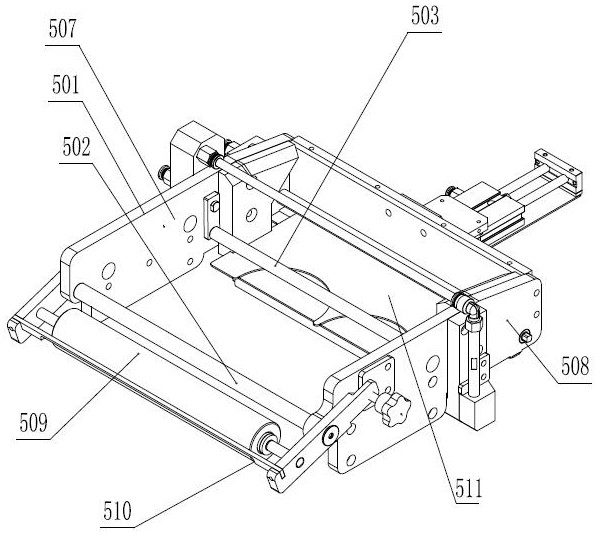

[0068] The noodle belt enters into the pressing roller part 300 through the front end noodle belt conveyor 200, squeezes the noodle belt, and drives the noodle belt forward to the end noodle belt conveyor 400, after the noodle belt comes out of the end noodle belt conveyor 400 , passing through the noodle strip blowing device 500 downwards, the noodle strip blowing device 500 changes the transmission direction of the noodle strip by blowing air, so that the noodle strip is transported to the bottom of the skinning device 600, and the skinning device 600 completes the skinning and cutting of the noodle strip Push down, and the residual skin after skin cutting enters the residual skin synchronous conveyor 700.

[0069] The cutter drive box 602 drives the cutter 606 in the skin punching box 601 to perform skin cutting and skin punching, and the powder dusting box 900 ...

Embodiment 2

[0074] A novel noodle belt conveying punching method is characterized in that it comprises the following steps:

[0075] The noodle belt enters into the pressing roller part 300 through the front end noodle belt conveyor 200, squeezes the noodle belt, and drives the noodle belt forward to the end noodle belt conveyor 400, after the noodle belt comes out of the end noodle belt conveyor 400 , passing through the noodle strip blowing device 500 downwards, the noodle strip blowing device 500 changes the transmission direction of the noodle strip by blowing air, so that the noodle strip is transported to the bottom of the skinning device 600, and the skinning device 600 completes the skinning and cutting of the noodle strip Push down, and the residual skin after skin cutting enters the residual skin synchronous conveyor 700.

[0076] The cutter drive box 602 drives the cutter 606 in the skin punching box 601 to perform skin cutting and skin punching, and the powder dusting box 900 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com