AlN film growing method

A thin film growth and thin film technology, which is applied in the direction of ion implantation plating, coating, electrical components, etc., can solve the problems of low production process output efficiency and insufficient process stability, so as to increase stability, prolong service life, improve The effect of productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

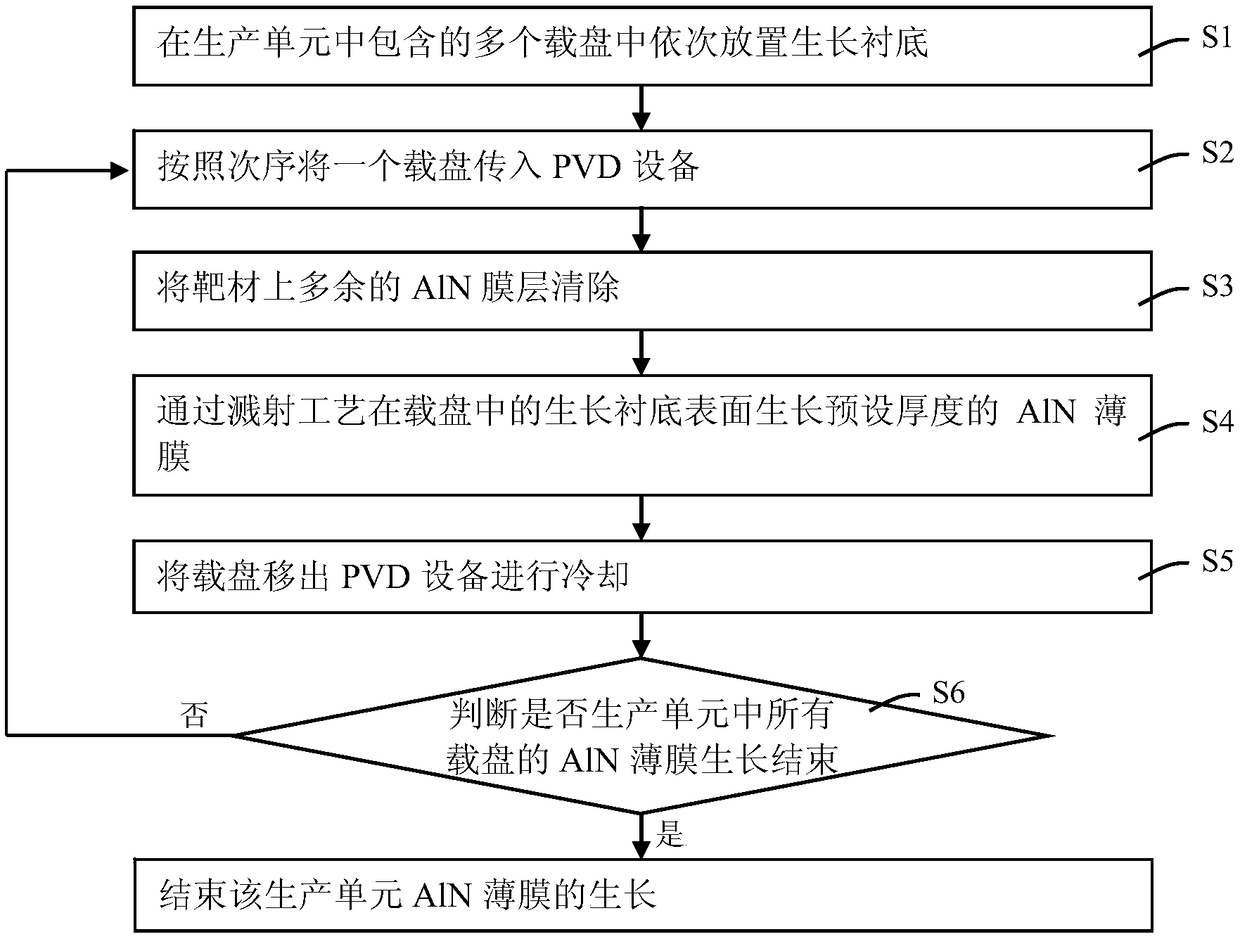

Method used

Image

Examples

Embodiment 1

[0022] Adjust the voltage of magnetron sputtering produced by AlN in PVD equipment to 250-260V (volts), fill 7 SIC carriers with 5 pieces of 4-inch PSS substrates respectively, and place them in the same plug as a production unit ;Place the plug in the loading chamber and vacuumize it, use the mechanical arm to transfer the first carrier plate to the reaction chamber, when the vacuum degree in the reaction chamber reaches 10E-7torr, and the temperature is heated to 650°C to stabilize, the A baffle is introduced from above, 200sccm of Ar gas is introduced, and the sputtering DC power is 3000W for 15s to remove the AlN film on the target. After that, pass 35sccm of Ar gas, 175sccm of N 2 , 2sccm O 2 , the sputtering power is 3400W, the magnetron sputtering voltage is controlled between 250-260V, the baffle is removed, and a 30nm (nanometer) thick AlN film is plated on the PSS substrate. After the growth is over, transfer the carrier plate to the cooling chamber to cool down, t...

Embodiment 2

[0024] Adjust the magnetron sputtering voltage produced by AlN in the PVD equipment to 250-260V, fill the seven SIC carriers with five 4-inch PSS substrates respectively, and place them in the same card as a production unit. The plug is placed in the loading chamber and vacuumed, and the first disk is transferred to the reaction chamber by a robot arm. When the vacuum degree in the reaction chamber reaches 10E-7torr and the temperature is heated to 650°C and stabilizes, a disk is introduced above the reaction disk. The baffle is fed with 200 sccm of Ar gas, and the sputtering DC power is 2400W for 12s to remove a layer of AlN film on the target. After that, pass 35sccm of Ar gas, 175sccm of N 2 , 2sccm O 2 , The sputtering power is 3400W, the magnetron sputtering voltage is controlled between 250-260V, the baffle is removed, and a 15nm thick AlN film is plated on the PSS substrate. After the growth is over, transfer the carrier plate to the cooling chamber to cool down, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com