Inductive thermal imaging non-destructive testing system based on novel high-efficiency open magnetic yoke coil structure

A yoke coil and non-destructive testing technology, which is applied in the direction of material magnetic variable and material defect testing, etc., can solve the problems of negative impact of defect detection, small detection area, small magnetic induction intensity, etc., and achieve good detection effect, uniform eddy current, eddy current enhanced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

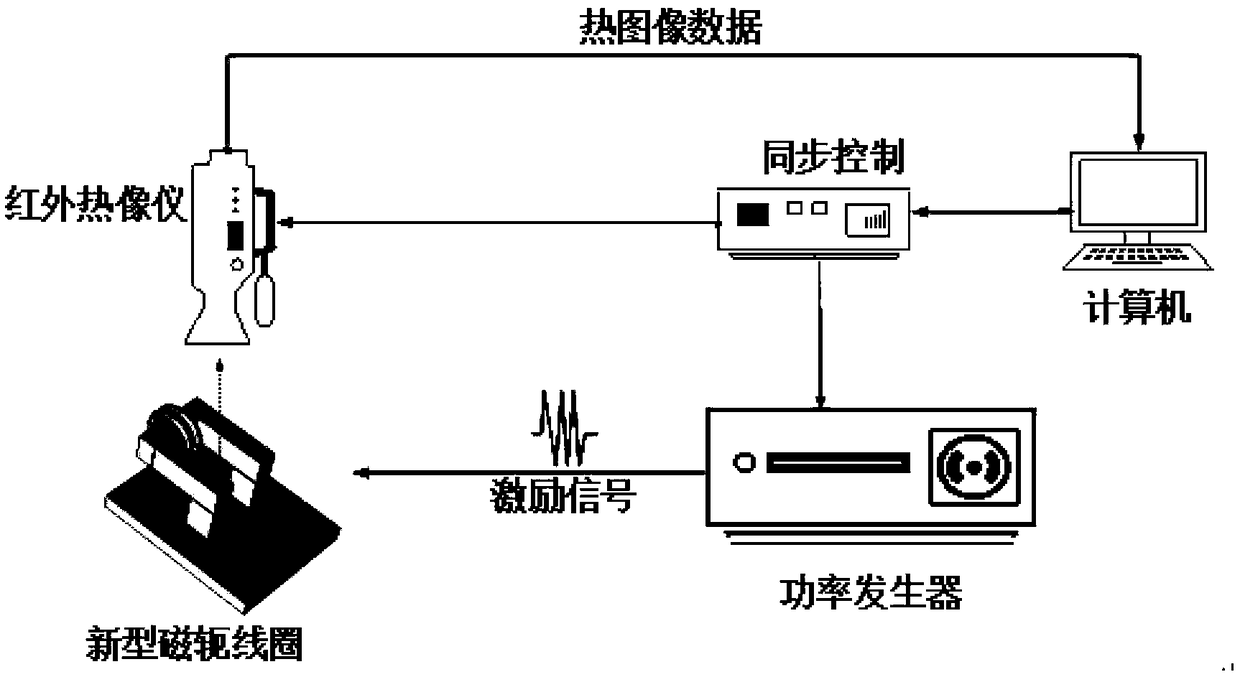

[0036] image 3 It is the principle diagram of the induction thermal image non-destructive testing system based on the new high-efficiency yoke coil structure of the present invention.

[0037] In this example, if image 3 As shown, the present invention is an induction thermal image non-destructive testing system based on a new high-efficiency yoke coil structure, including: a power generator, an infrared camera, a computer, a synchronous controller and a new high-efficiency yoke coil.

[0038] Wherein, the synchronous controller is respectively connected with the power generator, the external trigger port of the infrared thermal imager and the computer interface, and generates the synchronous control pulse signal of the power generator and the infrared thermal imager according to the parameters set by the computer;

[0039] The power generator is used to generate alternating excitation current and pass it into the excitation coil; the infrared thermal imager is used to coll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com