Engine induction manifold

A technology of intake manifold and engine, which is applied in the direction of combustion engine, machine/engine, internal combustion piston engine, etc. It can solve the problems of uneven eddy current and achieve the effect of uniform eddy current and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

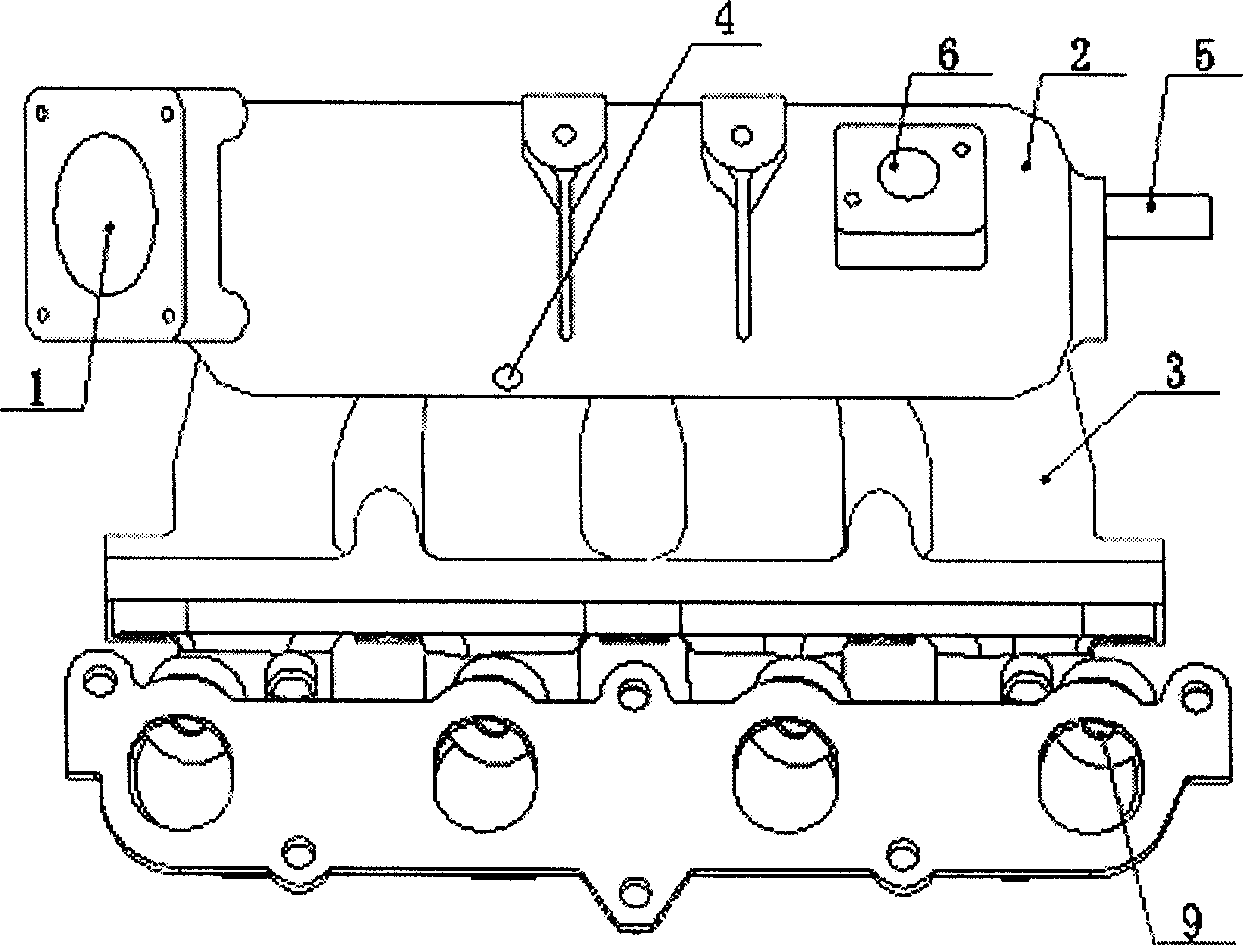

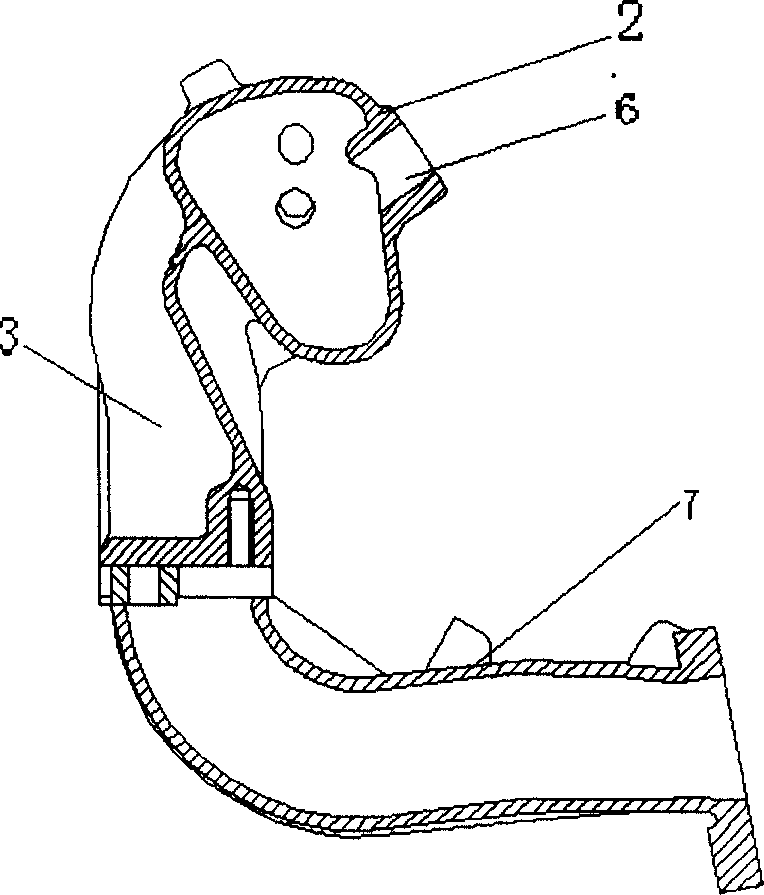

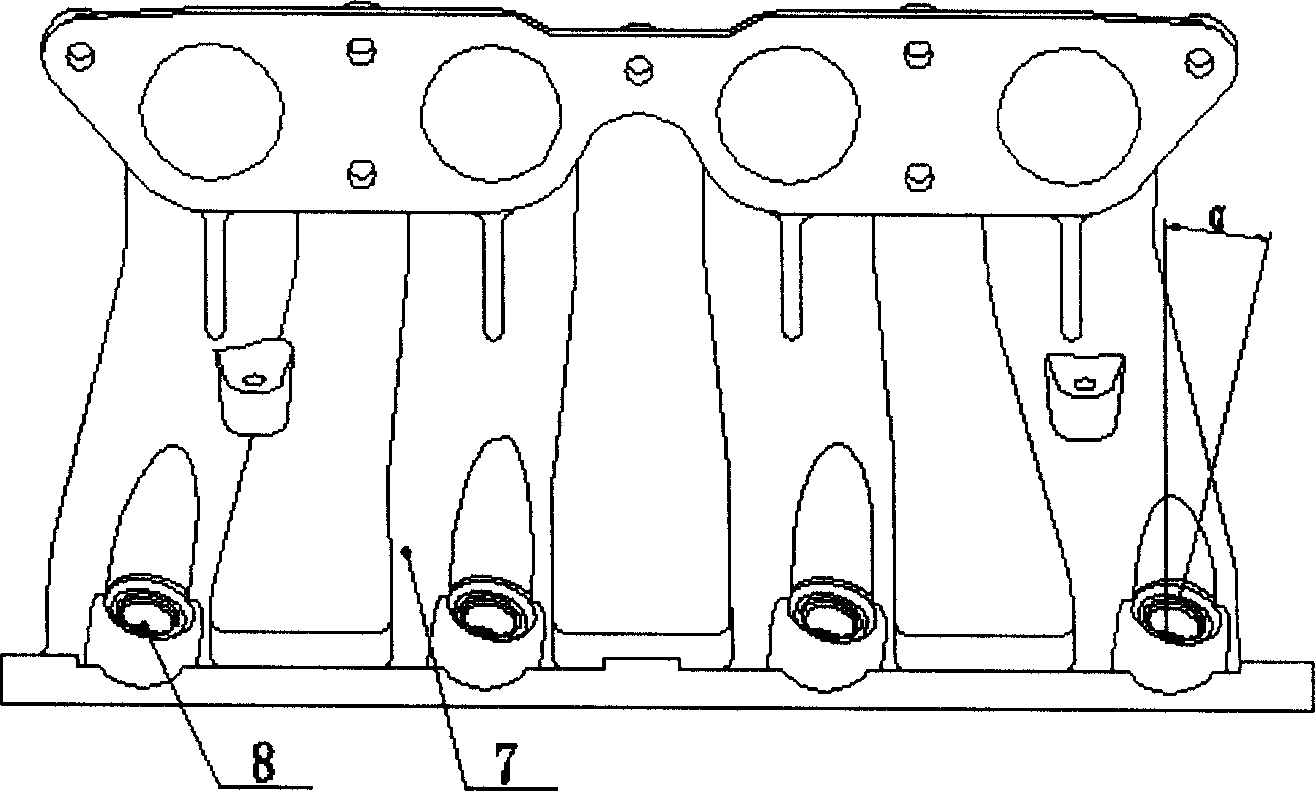

[0017] exist figure 1 , 2 In the four-cylinder engine intake manifold embodiment shown in , 3 and 4, an engine intake manifold includes an upper body that collects flow and a lower body that disperses flow. The upper body has an air inlet 1, a resonance cavity 2 and a set of bent upper body tubes 3; the lower body has a set of lower body tubes 7 adapted to the bent upper body tubes 3, and electrospray holes 8 And air outlet 9. The upper body is also provided with a sensor mounting hole 6, a crankcase ventilation pipe joint 4 and a vacuum pipe joint 5, and a group of bent upper body pipes 3 are arranged in parallel. The crankcase ventilation pipe joint 4 is located in the middle of the upper body, and the vacuum pipe joint 5 is located at the tail end of the upper body.

[0018] Such as image 3 As shown, the angle between the electrospray hole 8 and the vertical plane is 13--15°.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com