A fixture and assembly method for unloading a two-rigid and one-soft true triaxial testing machine

A triaxial test and fixture technology, applied in the field of rock true triaxial test rock sample fixtures, can solve problems such as research and analysis, unfavorable, unilateral restrictions on rock samples, etc., and achieve the effects of low price, cost saving, and convenient rock sample assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

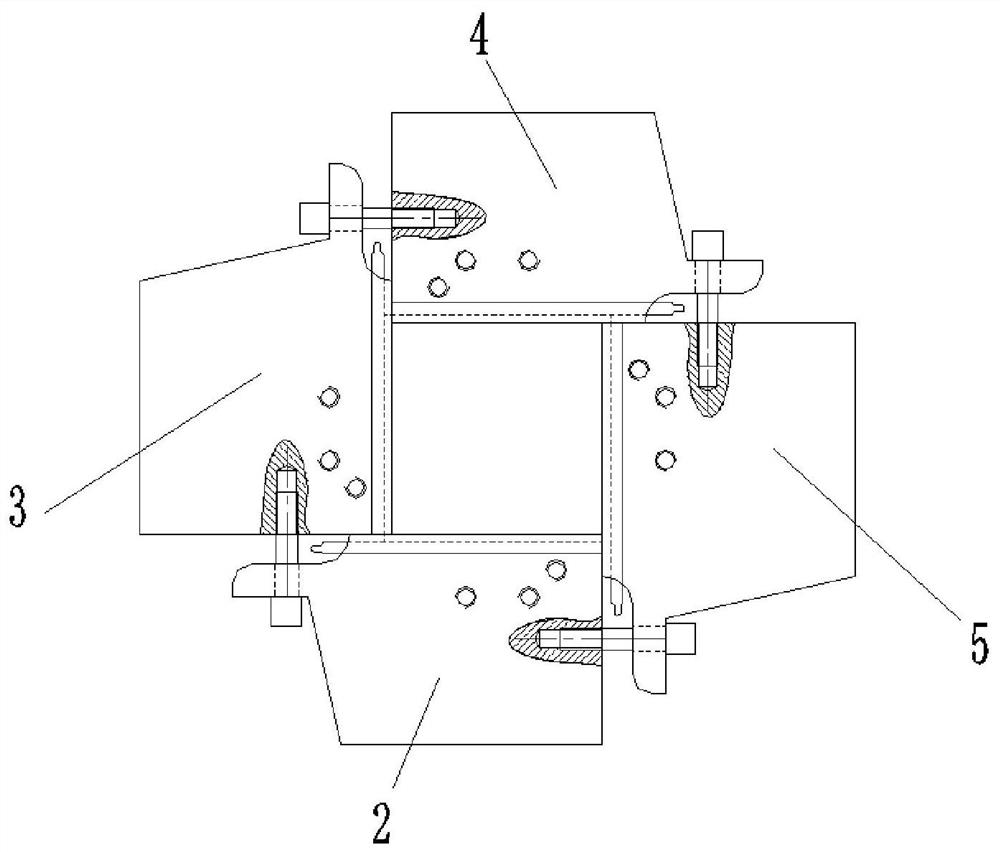

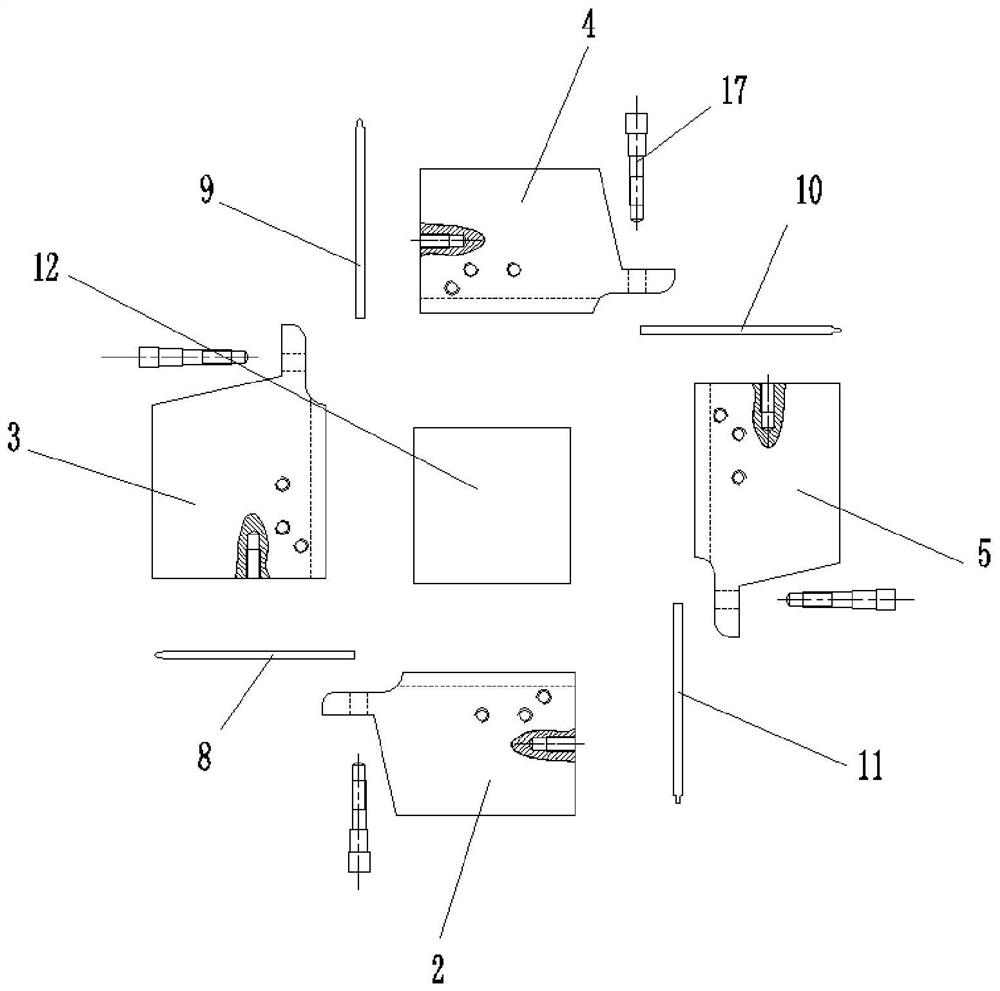

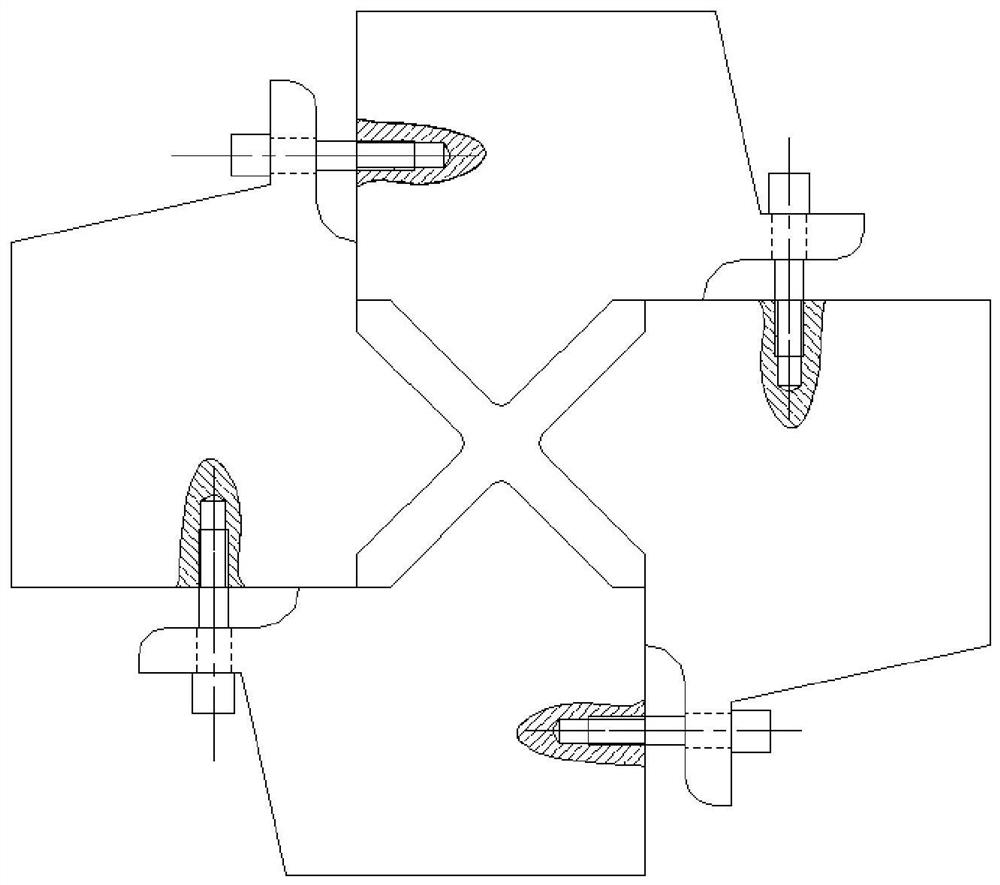

[0035] Such as Figure 1-Figure 3 As shown, a fixture for unloading a two-rigid-soft true triaxial testing machine includes four pressing blocks 1, namely the first pressing block 2, the second pressing block 3, the third pressing block 4 and the fourth pressing block The briquetting block 5, the groove 6 of the first briquetting block 2, the second briquetting block 3, the third briquetting block 4 and the fourth briquetting block 5 are all provided with position control posts, and the first briquetting block 2, the second briquetting block The grooves 6 of the block 3, the third briquetting block 4 and the fourth briquetting block 5 are connected end to end to form a square groove, and a limiting baffle 12 is arranged in the square groove, and the four surfaces of the limiting baffle 12 are attached to the surface of the position control col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com