Supersensitivity leakage detecting device with lower limit being 10<-16> Pam<3>/s and method

An ultra-sensitive, leak-detecting technology, used in the testing of measuring devices, machines/structural components, and liquid/vacuum tightness measurement, etc. The effect of bottom pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

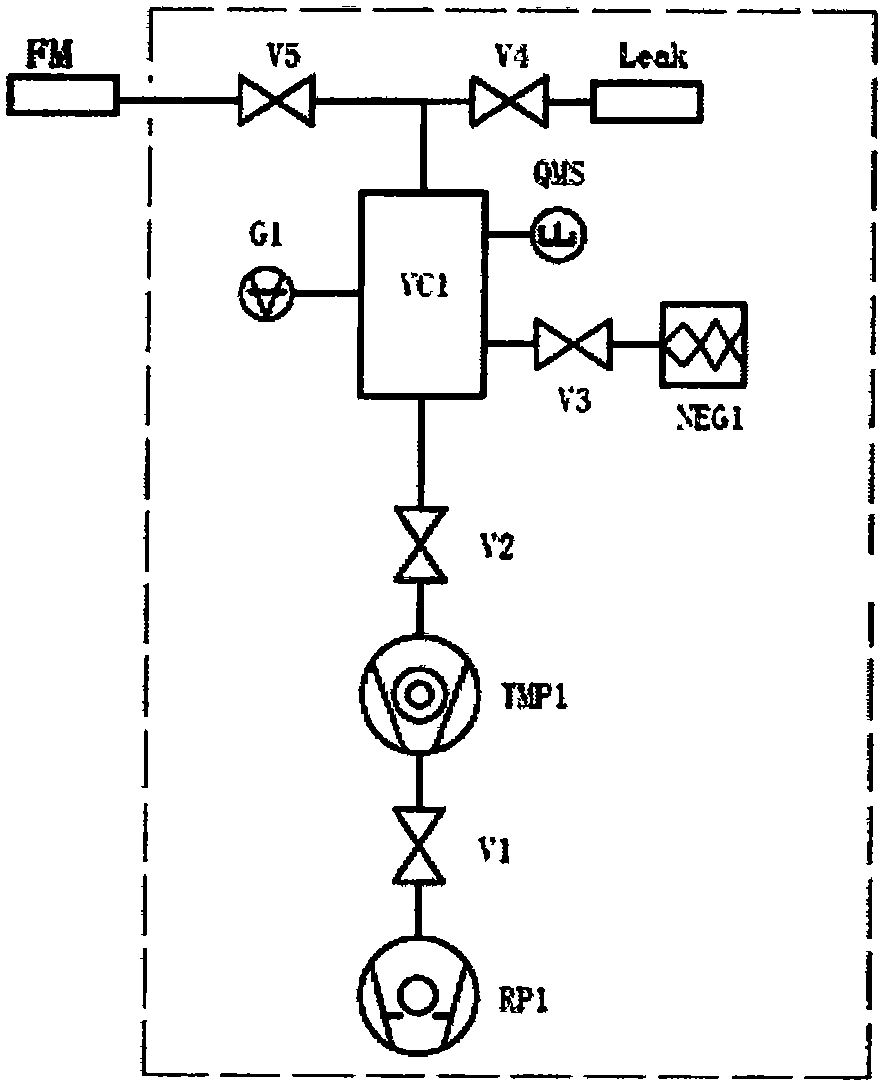

[0038] S1. Turn on the power supply of the device and open the air source for supplying air to the flapper valve; start the detection program, and the program performs self-inspection on the status of the valve and pump;

[0039] S2. Turn on the vacuum gauge G1; install the leak of the tested sample on the fourth vacuum valve V4, and open the fourth vacuum valve V4 and the fifth vacuum valve V5;

[0040] S3. Start the mechanical pump RP1, open the first vacuum valve V1 and the second vacuum valve V2, and start the molecular pump TMP1 to pump air to the leak detection system after the value of the vacuum gauge G1 is less than 100Pa. The indicated value is 8.9×10 - 5 Pa, turn on the quadrupole mass spectrometer QMS;

[0041] S4. The vacuum indicated by the vacuum gauge G1 is 6.8×10 -6 At Pa, the QMS detects that the ion current of He is 5.0E-14A, and closes the fourth vacuum valve V4 and the fifth vacuum valve V5;

[0042] S5, open the third vacuum valve V3, start the getter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com