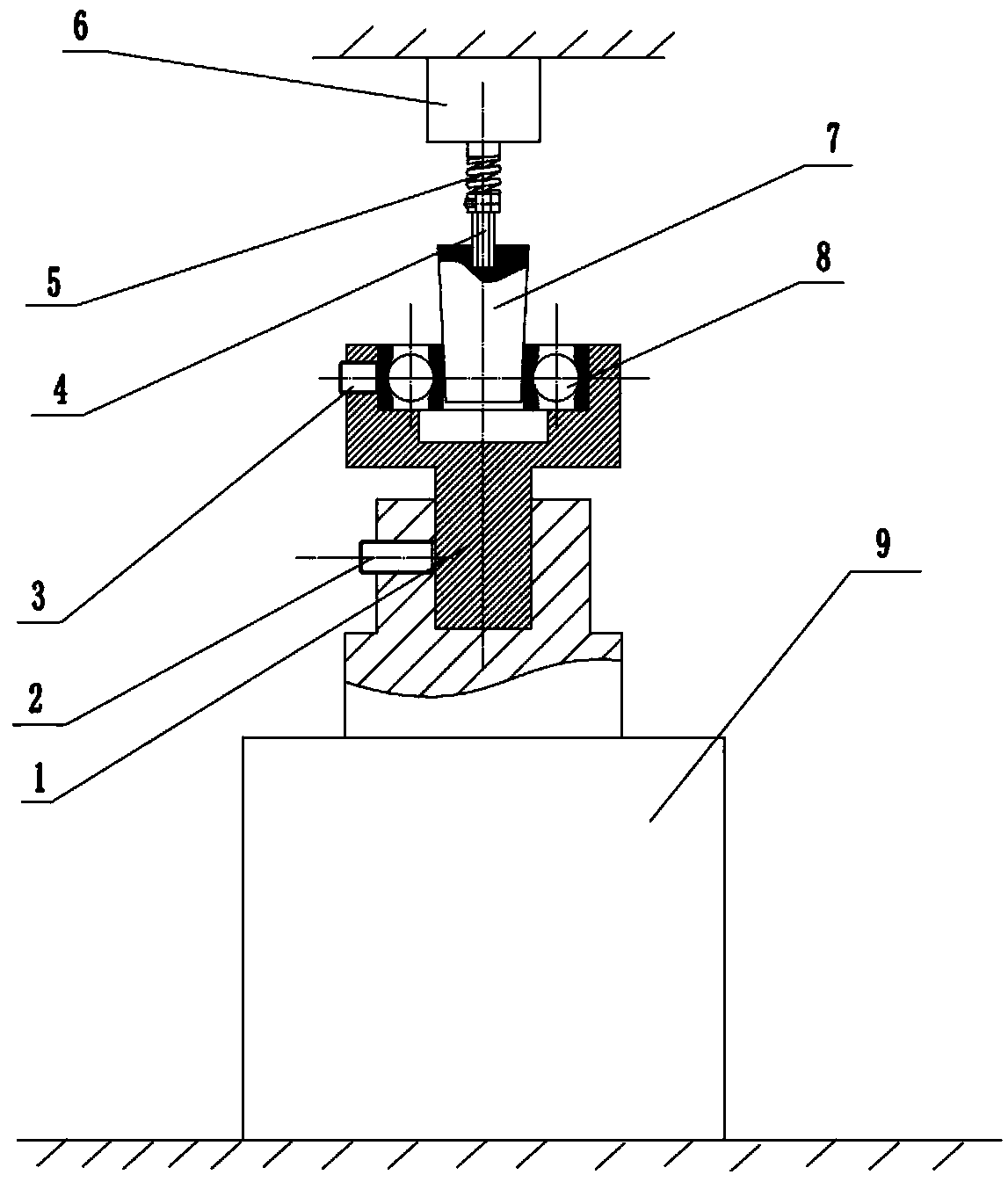

Rolling bearing no-load starting torque measuring device

A technology for starting torque and measuring devices, applied in measuring devices, force/torque/work measuring instruments, mechanical bearing testing, etc., can solve problems such as crushing, and achieve easy installation, small positive pressure, and low processing accuracy requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0039] The following is an example of the measurement test of the starting torque and rotation torque of a sealed deep groove ball bearing.

[0040] The sealed deep groove ball bearing has an outer diameter of 26mm, an inner diameter of 10mm, an outer ring width of 8mm, and an inner ring width of 12mm.

[0041] According to the structure of the bearing, the corresponding test fixture is designed, in which the bearing seat is made of 45 steel material, and the measuring mandrel is made of soft nylon material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com