Joint adaptor for connecting reinforced concrete column and steel beams and connecting structure of reinforced concrete column and steel beams

A reinforced concrete column and node transfer technology, which is applied in building structures and buildings, can solve the problems of difficult direct penetration of node domains, fighting between columns and steel beams, and long construction process, so as to reduce the cost of node connection and reduce the additional load. , the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The node adapter for connecting reinforced concrete columns and steel beams and its connection structure proposed by the present invention will be described in more detail below in conjunction with schematic diagrams, wherein a preferred embodiment of the present invention is shown, and it should be understood that those skilled in the art can modify The invention described herein, while still achieving the advantageous effects of the invention. Therefore, the following description should be understood as the broad knowledge of those skilled in the art, but not as a limitation of the present invention.

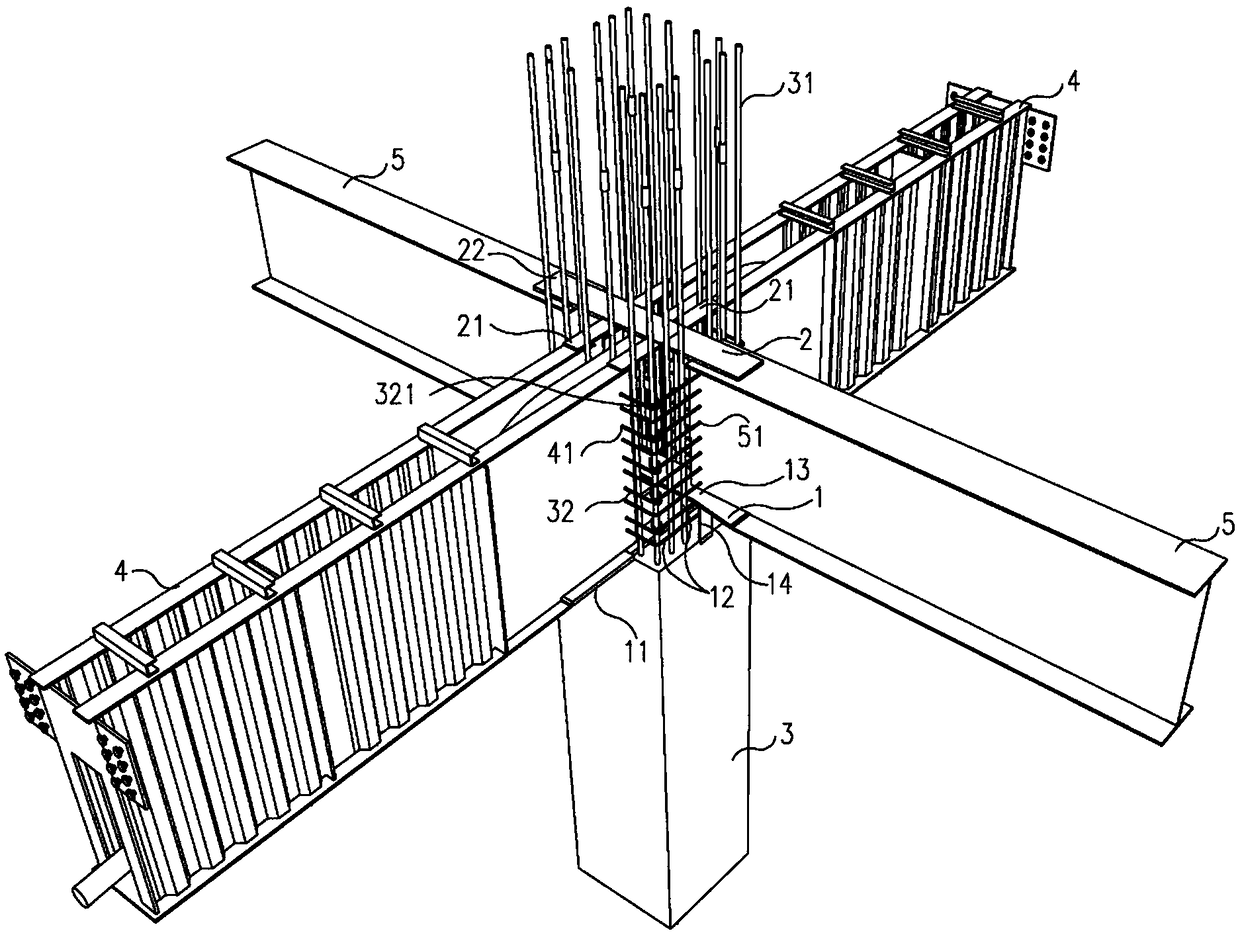

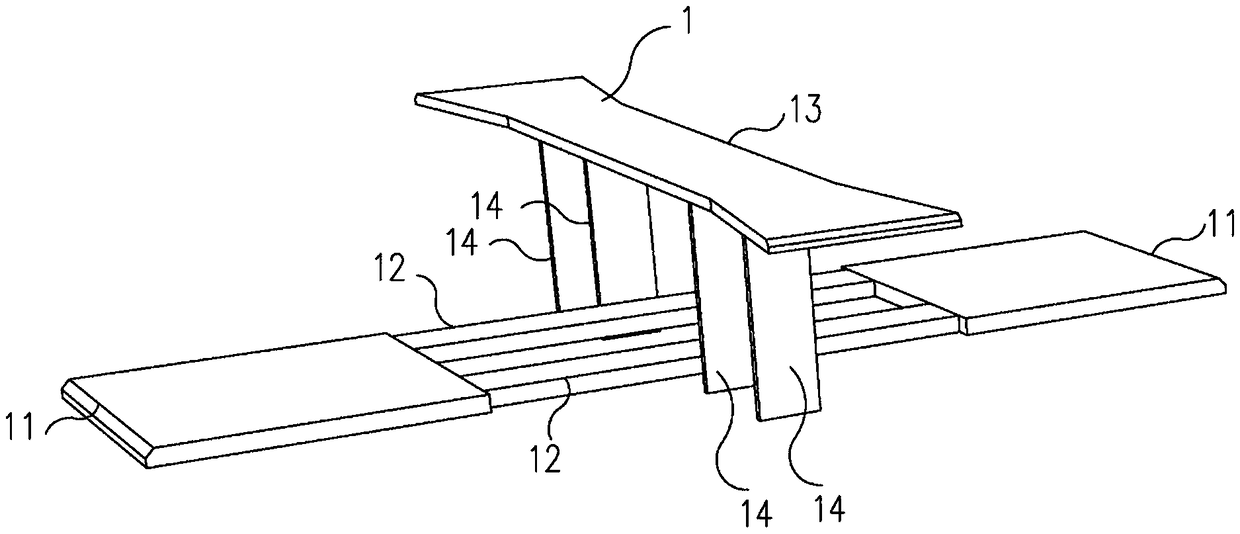

[0030] See for details image 3 , Figure 4 and Figure 5, the present invention proposes a node adapter for connecting reinforced concrete columns and steel beams, including a superior node lower flange 1 and a superior node upper flange 2; the superior node lower flange 1 is located on the superior node upper flange Below the edge 2; the lower flange 1 of the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com