Short-process smelting reduction type iron-making system and method

A short process, iron ore powder technology, applied in the field of ironmaking, can solve the problems of blast furnace development crisis, air pollution, long production process, etc., and achieve the effect of full reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

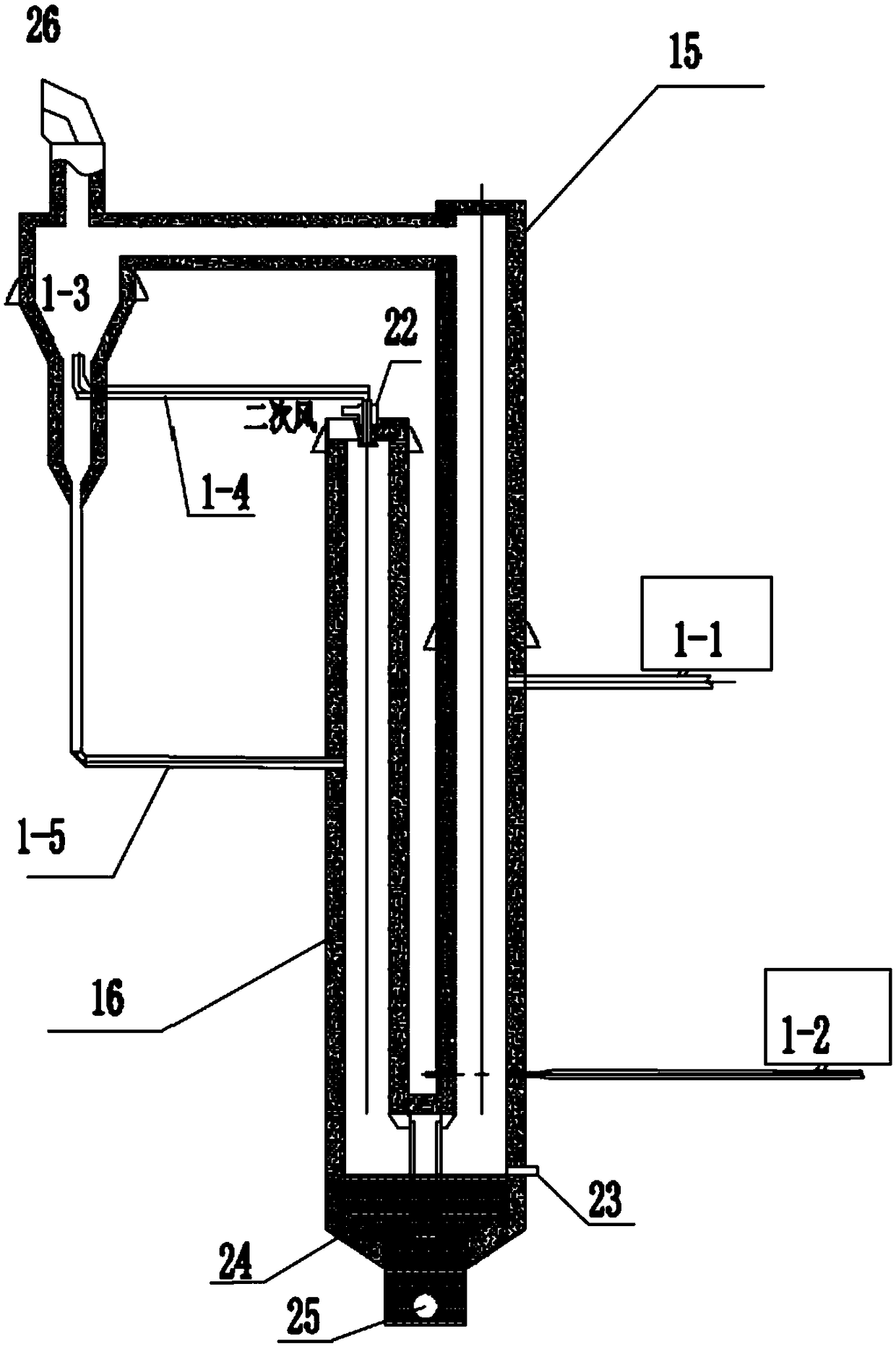

[0050] Such as figure 1 shown

[0051] A short-flow smelting reduction ironmaking system, including coal powder preparation device 1-1, iron ore powder preparation device 1-2, iron ore powder direct reduction and powder coke preparation device, gas-solid separation device 1-3; iron ore powder The direct reduction and powder coke preparation device is a U-shaped structure connected at the bottom. The two sides are respectively a low-temperature reduction section 15 and a high-temperature reduction section 16. The bottom is a melting reduction section 24. The coal powder preparation device 1-1, iron ore powder preparation Devices 1-2 are respectively connected to the middle and bottom of the low-temperature reduction section 15, the low-temperature reduction section 15 is connected to the gas-solid separation device 1-3, and the gas-solid separation device 1-3 is respectively connected to the top burner 22 and the middle part of the high-temperature reduction section 16 .

Embodiment 2

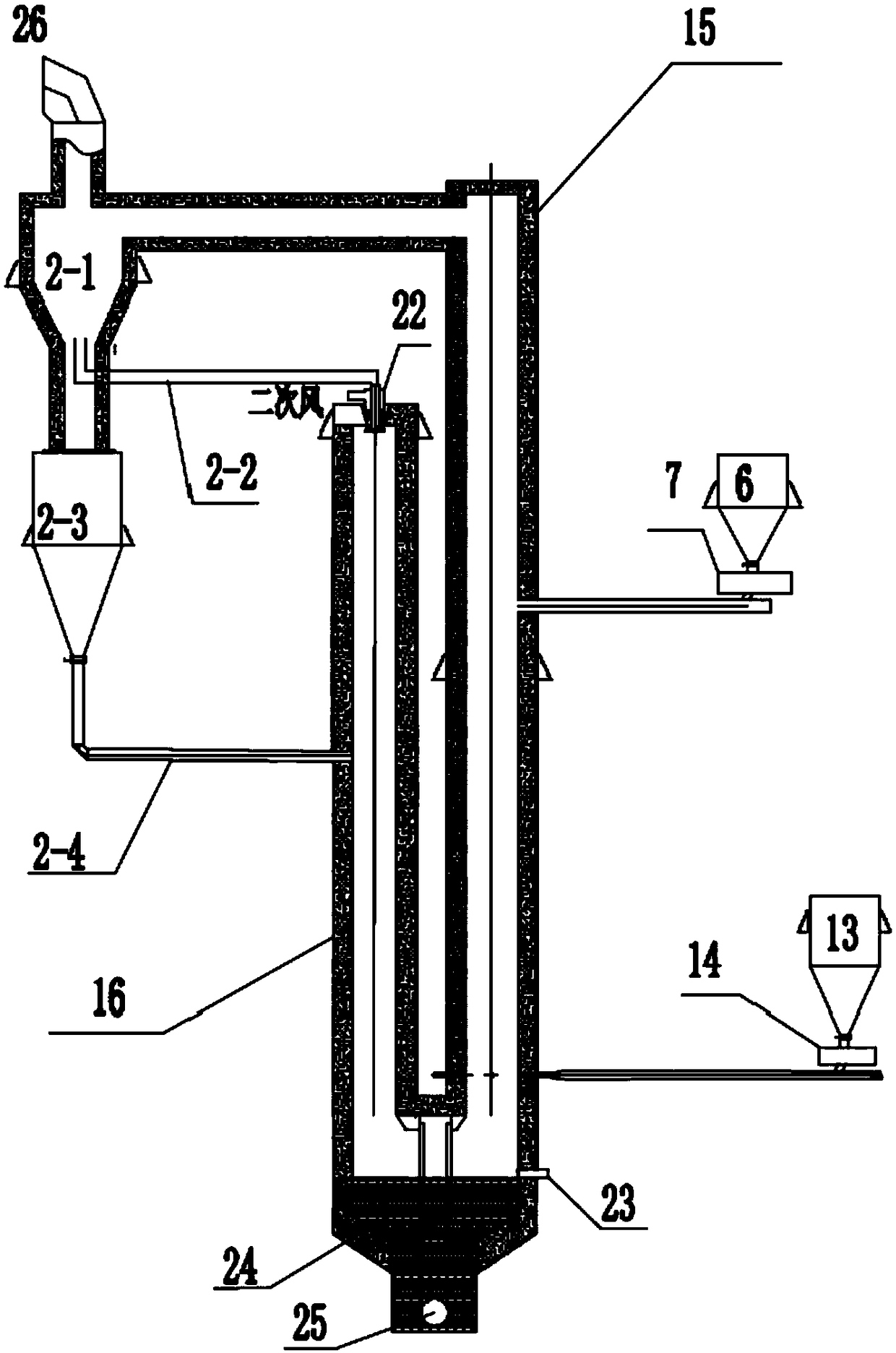

[0053] Such as figure 2 shown

[0054] A short-flow smelting reduction ironmaking system, including coal powder preparation device 1-1, iron ore powder preparation device 1-2, iron ore powder direct reduction and powder coke preparation device, gas-solid separation device 1-3; iron ore powder The direct reduction and powder coke preparation device is a U-shaped structure connected at the bottom. The two sides are respectively a low-temperature reduction section 15 and a high-temperature reduction section 16. The bottom is a melting reduction section 24. The coal powder preparation device 1-1, iron ore powder preparation Devices 1-2 are respectively connected to the middle and bottom of the low-temperature reduction section 15, the low-temperature reduction section 15 is connected to the gas-solid separation device 1-3, and the gas-solid separation device 1-3 is respectively connected to the top burner 22 and the middle part of the high-temperature reduction section 16 .

[...

Embodiment 3

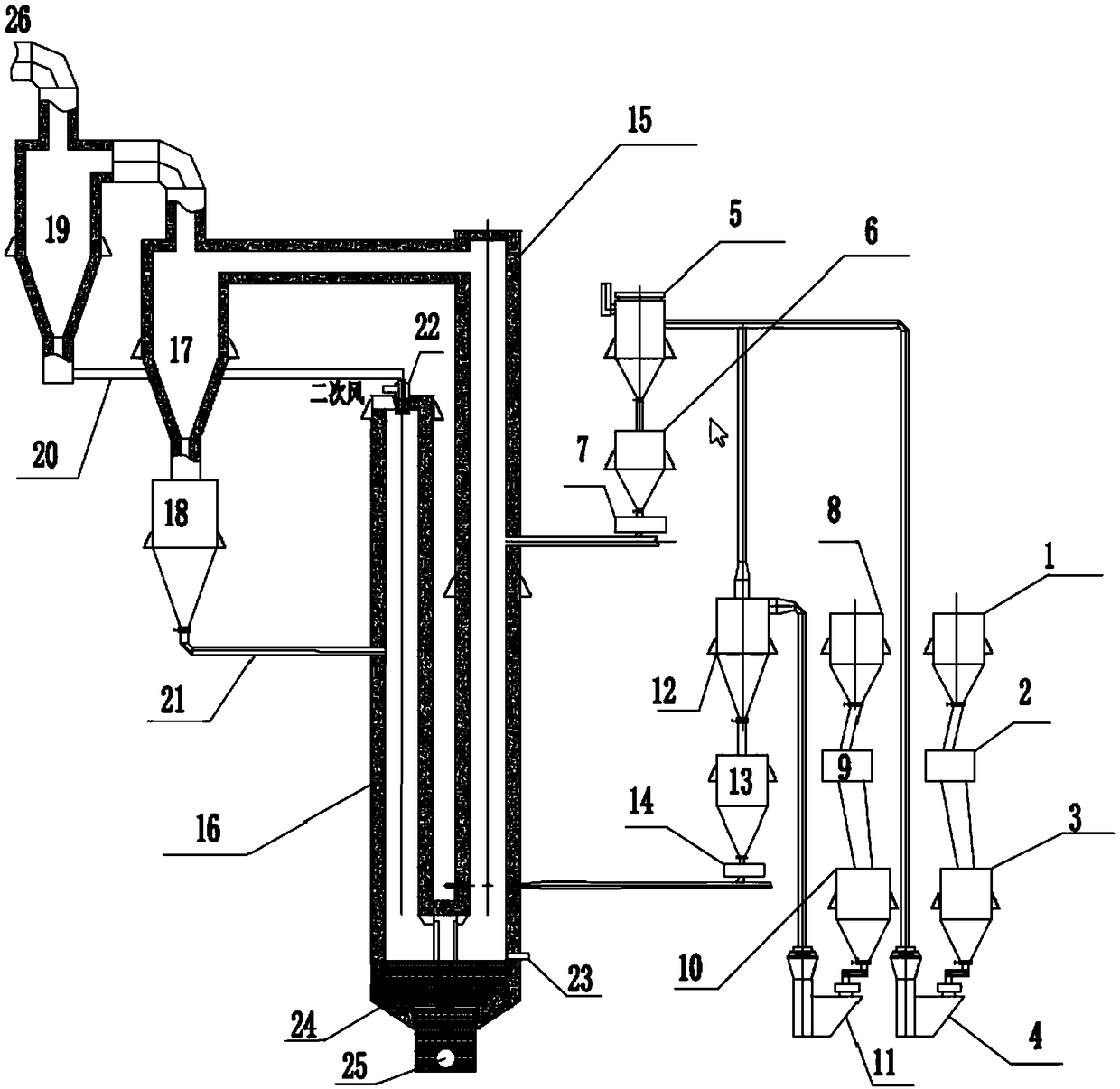

[0060] Such as image 3 shown

[0061] A short-flow smelting reduction ironmaking system, including coal powder preparation device 1-1, iron ore powder preparation device 1-2, iron ore powder direct reduction and powder coke preparation device, gas-solid separation device 1-3; iron ore powder The direct reduction and powder coke preparation device is a U-shaped structure connected at the bottom. The two sides are respectively a low-temperature reduction section 15 and a high-temperature reduction section 16. The bottom is a melting reduction section 24. The coal powder preparation device 1-1, iron ore powder preparation Devices 1-2 are respectively connected to the middle and bottom of the low-temperature reduction section 15, the low-temperature reduction section 15 is connected to the gas-solid separation device 1-3, and the gas-solid separation device 1-3 is respectively connected to the top burner 22 and the middle part of the high-temperature reduction section 16 .

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com