Electric vehicle light snoot coating paint and preparation method thereof

A technology for concentrators and electric vehicles, applied in primers, polyester coatings, coatings, etc., can solve the problems of low heat resistance, poor weather resistance, weak adhesion, etc., and achieve excellent performance and excellent performance. Adhesion, fast drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

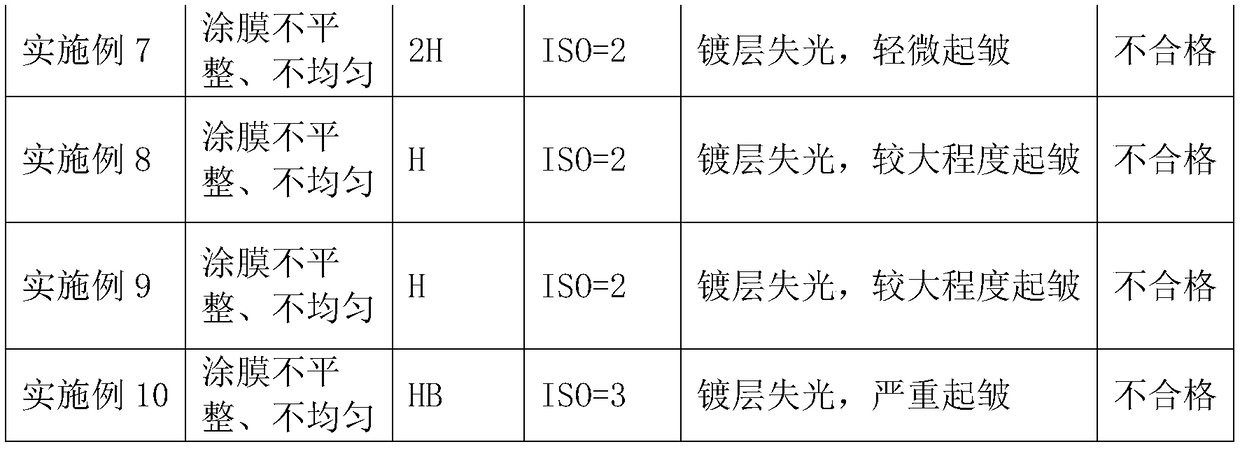

Examples

Embodiment 1

[0060] Embodiment 1 provides, on the one hand, a coating primer for the spotlight cover of an electric vehicle lamp, comprising the following raw materials in parts by weight: 30 parts of modified alkyd resin, 35 parts of modified phenolic resin, 33.38 parts of solvent, drying 1.41 parts of agent, 0.01 part of silicone oil, 0.2 parts of anti-skinning agent.

[0061] In this example, the modified alkyd resin is a mixture of medium-oil linseed oil-modified alkyd resin and short-oil linseed oil-modified alkyd resin, and the corresponding weight ratio is 23:7; the modified phenolic The resin is rosin modified phenolic resin; the solvent is 200# solvent and 120# solvent, and the corresponding weight ratio is 15:18.38; the drier is cobalt isooctanoate, zirconium isooctanoate, manganese isooctanoate, isooctanoate The calcium mixture has a corresponding weight ratio of 0.25:0.75:0.16:0.25; the silicone oil is polyether-modified polyorganosiloxane; and the anti-skinning agent is methyl...

Embodiment 2

[0068] Embodiment 2 provides on the one hand a kind of coating primer for the spotlight cover of electric vehicle lights, including the following raw materials in parts by weight: 10 parts of modified alkyd resin, 20 parts of modified phenolic resin, 20 parts of solvent, drying 0.8 part of agent, 0.005 part of silicone oil, 0.1 part of anti-skinning agent.

[0069] In this example, the modified alkyd resin is a mixture of medium-oil linseed oil-modified alkyd resin and short-oil linseed oil-modified alkyd resin, and the corresponding weight ratio is 23:7; the modified phenolic The resin is rosin modified phenolic resin; the solvent is 200# solvent and 120# solvent, and the corresponding weight ratio is 15:18.38; the drier is cobalt isooctanoate, zirconium isooctanoate, manganese isooctanoate, isooctanoate The calcium mixture has a corresponding weight ratio of 0.25:0.75:0.16:0.25; the silicone oil is polyether-modified polyorganosiloxane; and the anti-skinning agent is methyl ...

Embodiment 3

[0076] Embodiment 3 provides, on the one hand, a coating primer for the spotlight cover of an electric vehicle lamp, comprising the following raw materials in parts by weight: 50 parts of modified alkyd resin, 50 parts of modified phenolic resin, 40 parts of solvent, drying 3 parts of agent, 0.015 parts of silicone oil, 0.3 parts of anti-skinning agent.

[0077] In this example, the modified alkyd resin is a mixture of medium-oil linseed oil-modified alkyd resin and short-oil linseed oil-modified alkyd resin, and the corresponding weight ratio is 23:7; the modified phenolic The resin is rosin modified phenolic resin; the solvent is 200# solvent and 120# solvent, and the corresponding weight ratio is 15:18.38; the drier is cobalt isooctanoate, zirconium isooctanoate, manganese isooctanoate, isooctanoate The calcium mixture has a corresponding weight ratio of 0.25:0.75:0.16:0.25; the silicone oil is polyether-modified polyorganosiloxane; and the anti-skinning agent is methyl eth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com