Inner-hole processing clamp of thin-walled part for numerical control lathe

A technology for CNC lathes and thin-walled parts. It is applied in the direction of manufacturing tools, metal processing equipment, and metal processing machinery parts. It can solve the problem of affecting the surface quality of processed products, the clamping force is not easy to control, and the clamping force is easy to clamp. And other problems, to achieve good roundness, improve product surface roughness, uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

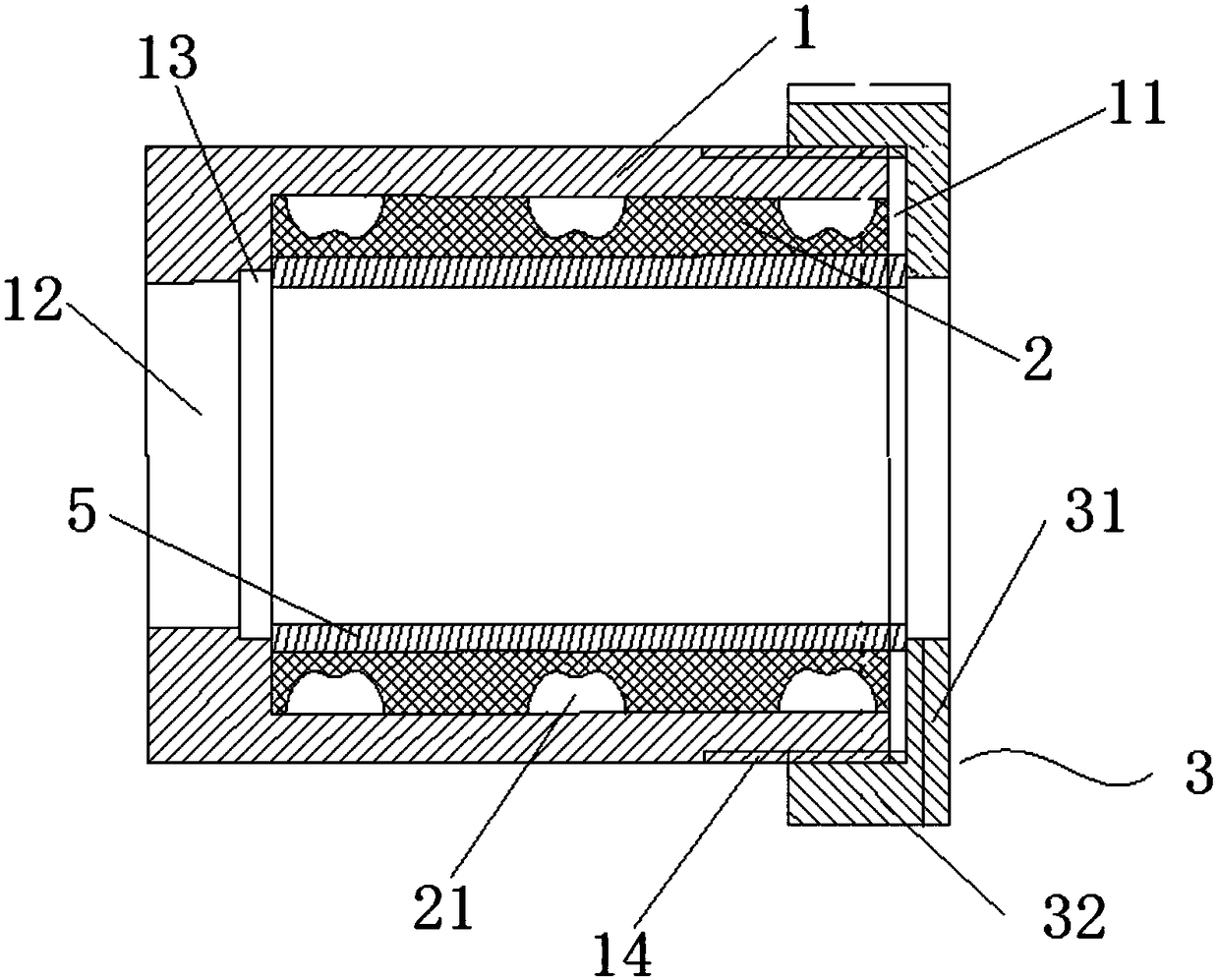

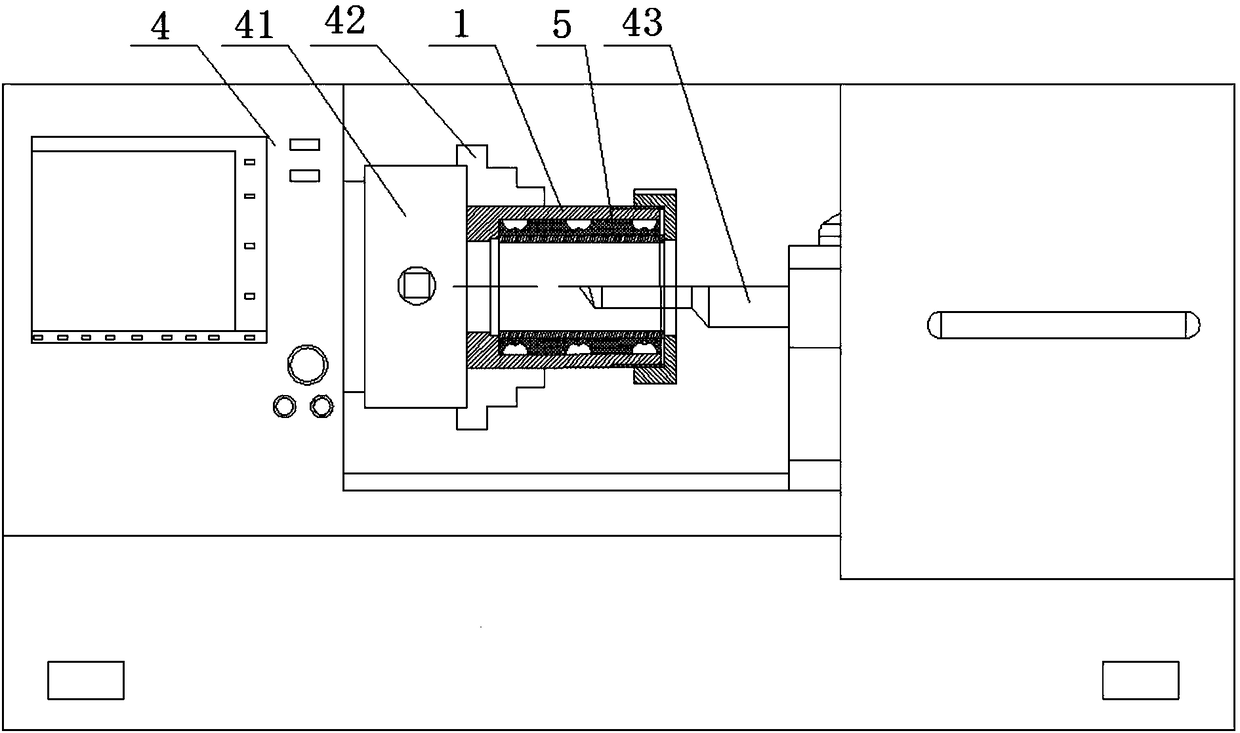

[0022] A jig for machining inner holes of thin-walled parts for CNC lathes, the structure of which is as follows figure 1 As shown, it includes a clamp body 1 sleeved on the outside of the workpiece 5 to be processed and fixed on the CNC lathe, and a clamp cover 3 installed on the front end of the clamp body 1 for clamping the workpiece 5 to be processed. During processing, the workpiece 5 to be processed is inserted into the Located inside the clamp body 1, the clamp cover 3 is fixed on the front end of the clamp body 1, and the clamp cover 3 presses the front end of the workpiece 5 to be processed.

[0023] The center of the clamp body 1 is provided with a columnar channel along the length direction of the clamp body 1. The channel is divided into a front section 11 and a rear section 12. A step 13 is formed between the front section 11 and the rear section 12. The inner diameter of the front section 11 is larger than the outer diameter of the workpiece 5 to be processed. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com