A kind of magnetic composite nanomaterial and its preparation method and application

A magnetic composite nano and magnetic nano technology, applied in the field of nano materials, can solve problems such as very different requirements, and achieve the effects of large surface area, increased adsorption capacity, and multiple adsorption sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] (mass ratio: 3-aminopropyltriethoxysilane: Fe 3 o 4 =14.19:1; Fe 3 o 4 : cellulose acetate = 20: 1; cellulose acetate: triolein = 6.67: 1)

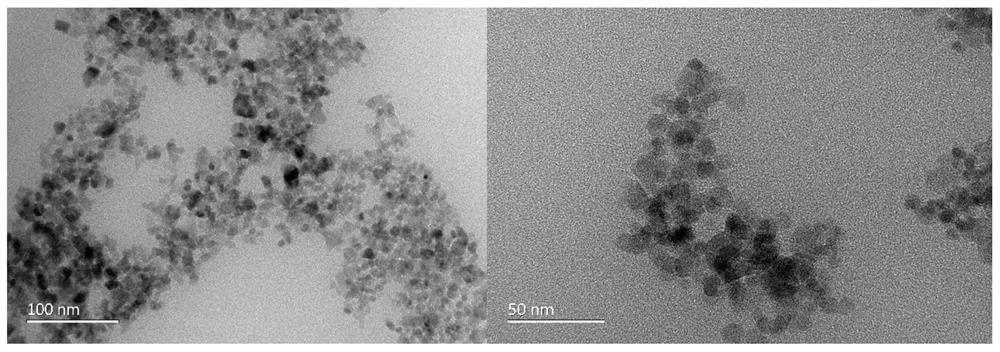

[0045] (1) Fe 3 o 4 Ferromagnetic nanoparticles were uniformly dispersed in absolute ethanol solution, and the volume was adjusted to 55mL to obtain 40mg / mL Fe 3 o 4 Ethanol dispersion of ferromagnetic nanoparticles.

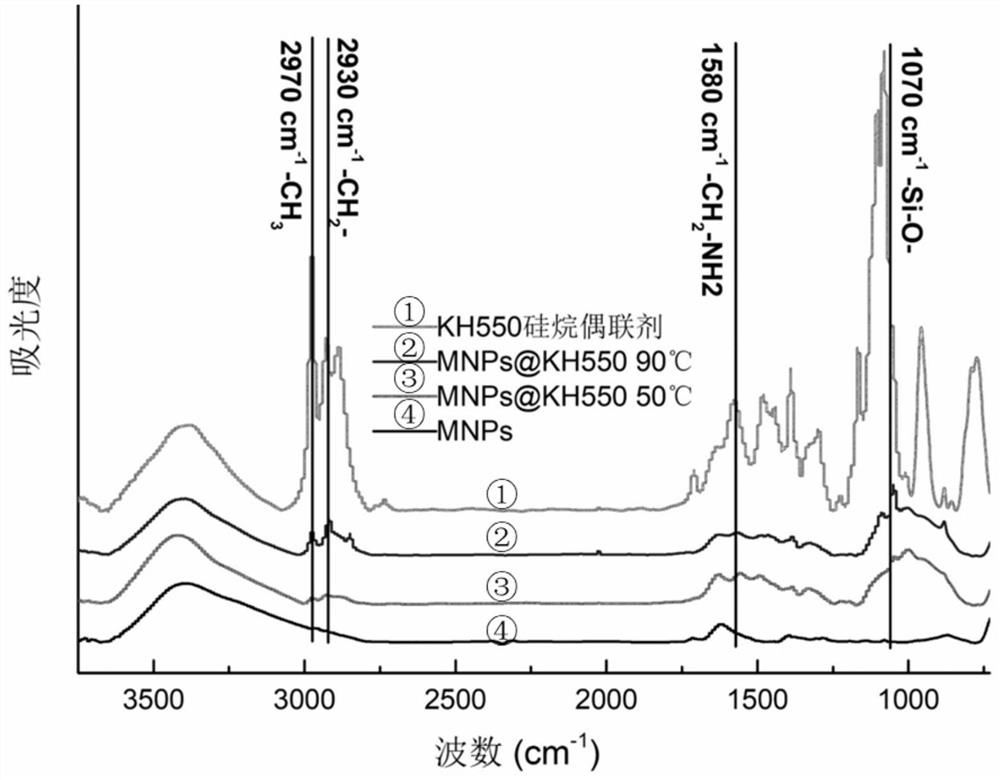

[0046] (2) 3 mL of 3-aminopropyltriethoxysilane (KH550) was dissolved in 40 mL of toluene organic solvent, and transferred to a three-neck round bottom flask. 5mLFe 3 o 4 Add the ethanol dispersion of ferromagnetic nanoparticles into the above-mentioned round bottom flask. Ultrasonic 5min, increase Fe 3 o 4 Dispersion of ferromagnetic nanoparticles and promote their uniform mixing with KH550. Under the condition of mechanical stirring at 350r / min and heating at 90°C, let KH550 and Fe 3 o 4 The ferromagnetic nanoparticles were reacted for 3 hours. Use the condensing reflux device to prevent toluene fro...

Embodiment 2

[0050] (mass ratio: 3-aminopropyltriethoxysilane: Fe 3 o 4 =15:1; Fe 3 o 4 : cellulose acetate = 16: 1; cellulose acetate: triolein = 6: 1)

[0051] (1) Fe 3 o 4 The ferromagnetic nanoparticles were evenly dispersed in absolute ethanol solution, and the volume was adjusted to 55mL to obtain a 40mg / mL MNPs ethanol dispersion.

[0052] (2) 2.28 mL of 3-aminopropyltriethoxysilane was dissolved in 40 mL of toluene organic solvent, and transferred to a three-neck round bottom flask. 3.6mLFe 3 o 4 Add the ethanol dispersion of ferromagnetic nanoparticles into the above-mentioned round bottom flask. Ultrasonic 2min, increase Fe 3 o 4 Dispersion of ferromagnetic nanoparticles and promote their uniform mixing with KH550. Under the conditions of mechanical stirring at 350r / min and heating at 50°C, let KH550 and Fe 3 o 4 The ferromagnetic nanoparticles were reacted for 3 hours. Use the condensing reflux device to prevent toluene from escaping from the bottle due to heating....

Embodiment 3

[0056] (mass ratio: 3-aminopropyltriethoxysilane: Fe 3 o 4 =15:1; Fe 3 o 4 : cellulose acetate = 23:1; cellulose acetate: triolein = 6:1)

[0057] (1) Fe 3 o 4 Ferromagnetic nanoparticles were uniformly dispersed in methanol solution, and the volume was adjusted to 40mL to obtain 50mg / mL Fe 3 o 4 Methanol dispersion of ferromagnetic nanoparticles.

[0058] (2) 3.28ml of 3-aminopropyltriethoxysilane was dissolved in 30ml of toluene organic solvent, and transferred to a three-neck round bottom flask. 4.14mLFe 3 o 4 The methanol dispersion of ferromagnetic nanoparticles was added to the above-mentioned round bottom flask. Ultrasonic 10min, increase Fe 3 o 4 Dispersion of ferromagnetic nanoparticles and promote their uniform mixing with KH550. Under the condition of mechanical stirring at 200r / min and heating at 45°C, let KH550 and Fe 3 o 4 The ferromagnetic nanoparticles were reacted for 2 hours. Use the condensing reflux device to prevent toluene from escaping fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com