Compound fertilizer production equipment

A technology for production equipment and compound fertilizers, applied to mixers, mixers with rotating stirring devices, dissolution, etc., can solve the problems of complex production equipment and high cost, and achieve simple structure, avoid jamming, and large loosening area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

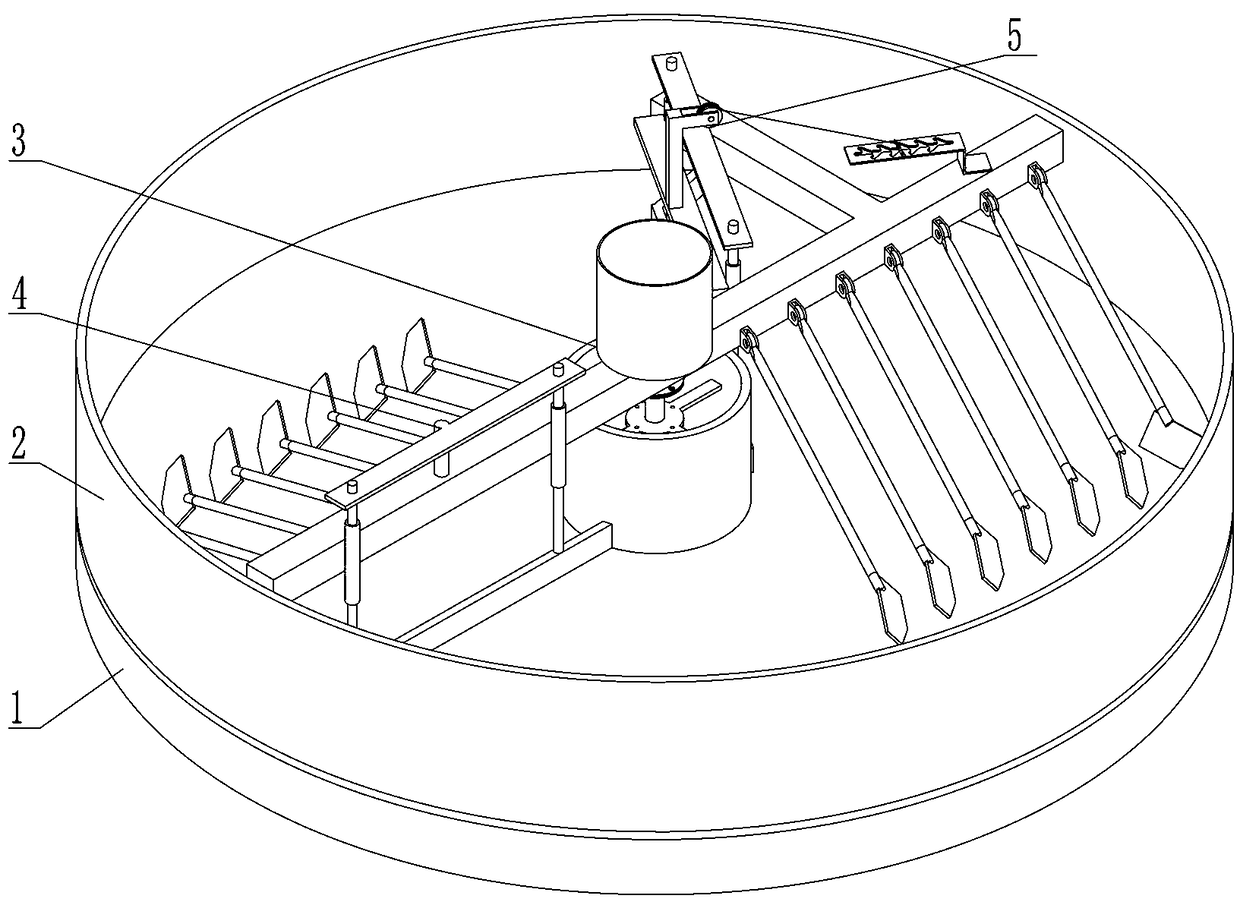

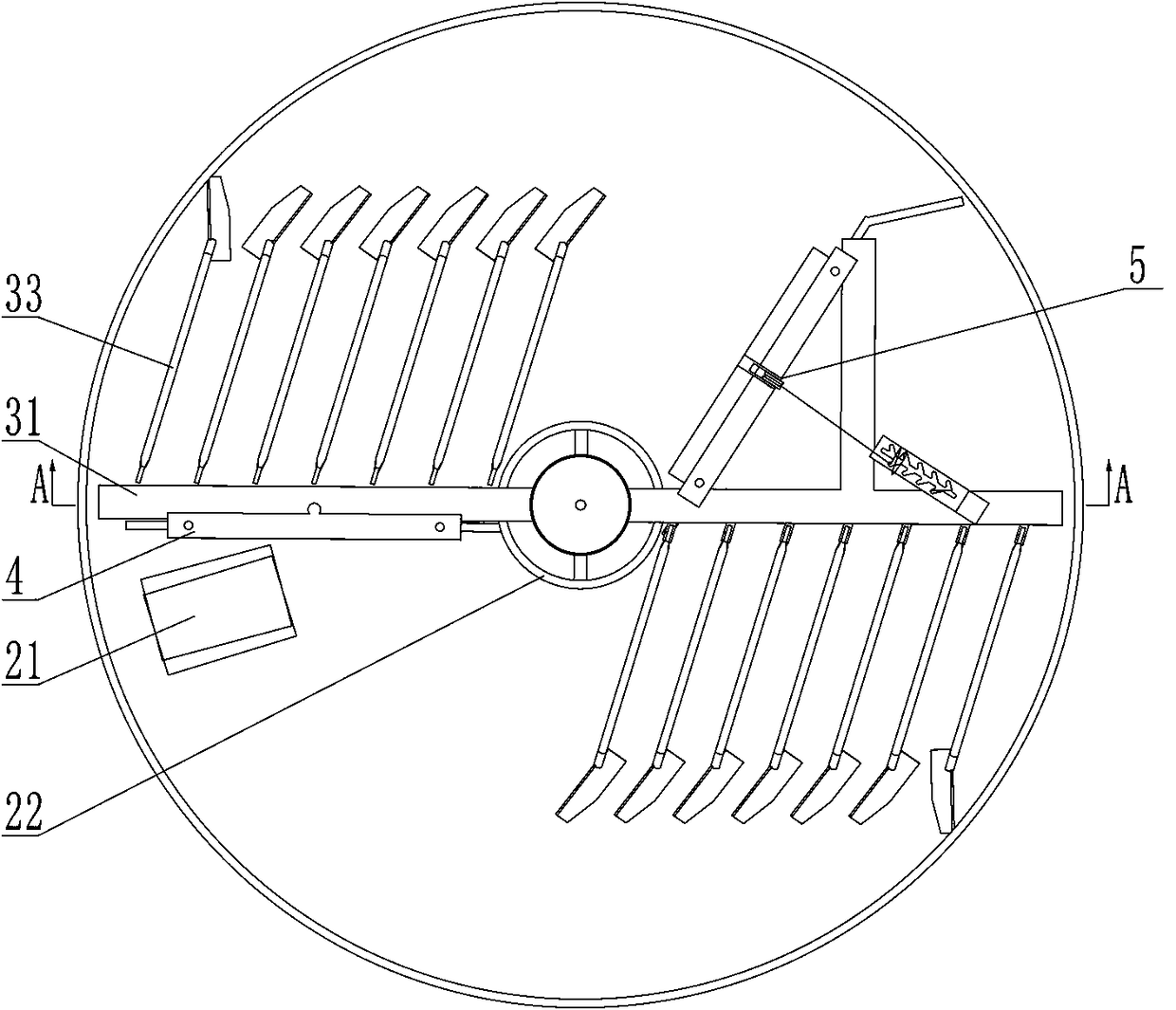

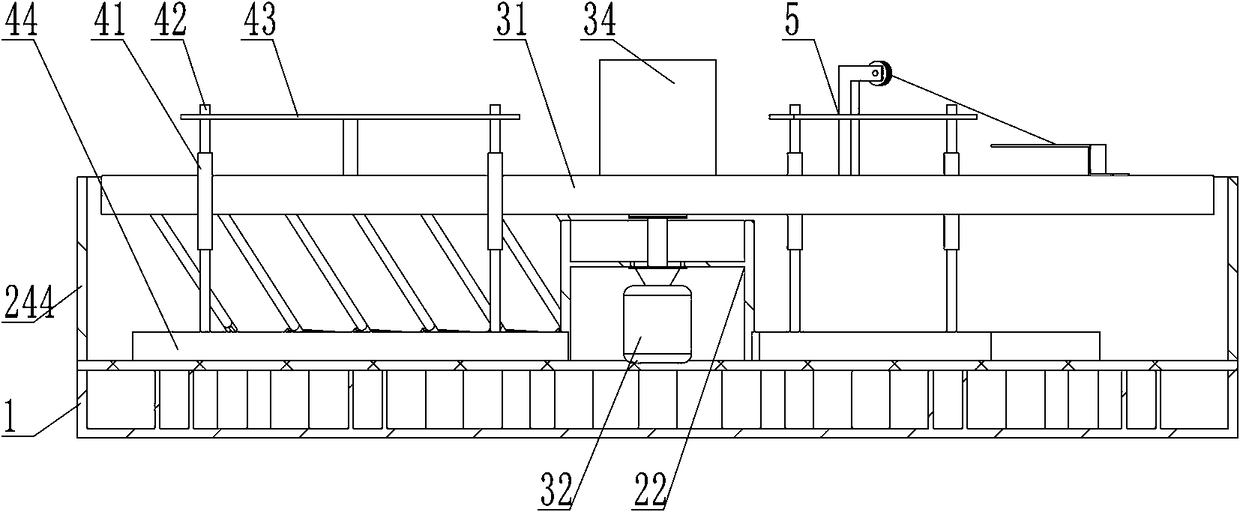

[0041] Such as Figure 1~Figure 12 Among them, a kind of compound fertilizer production equipment, it comprises heating device 1, feeding basin 2, material mixing device 3, material loosening mechanism 4 and scraping material mechanism 5; Located in the material basin 2 and connected thereto, the material loosening mechanism 4 and the material scraping mechanism 5 are located at both ends of the material mixing device 3 and connected; the material mixing device 3 drips and rotates the material. The structure is simple, by setting the material basin 2 on the upper side of the heating device 1 in contact with it, and setting the mixing device 3 in the material basin 2, and connecting the loosening mechanism 4 and the scraping mechanism 5 with both ends of the mixing device 3, and driven by the motor 32 The rotation of the cantilever 31 drives the rake teeth 33 to rotate and loosen the material body. The loosening mechanism 4 and the scraping mechanism 5 rotate the loosening and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com