Rotary clamping device

A rotary clamping device and clamping technology, applied in transportation and packaging, furnace, electric charge manipulation, etc., can solve the problems of substrate quality and yield reduction, small operating range, and large restoring force of compression springs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

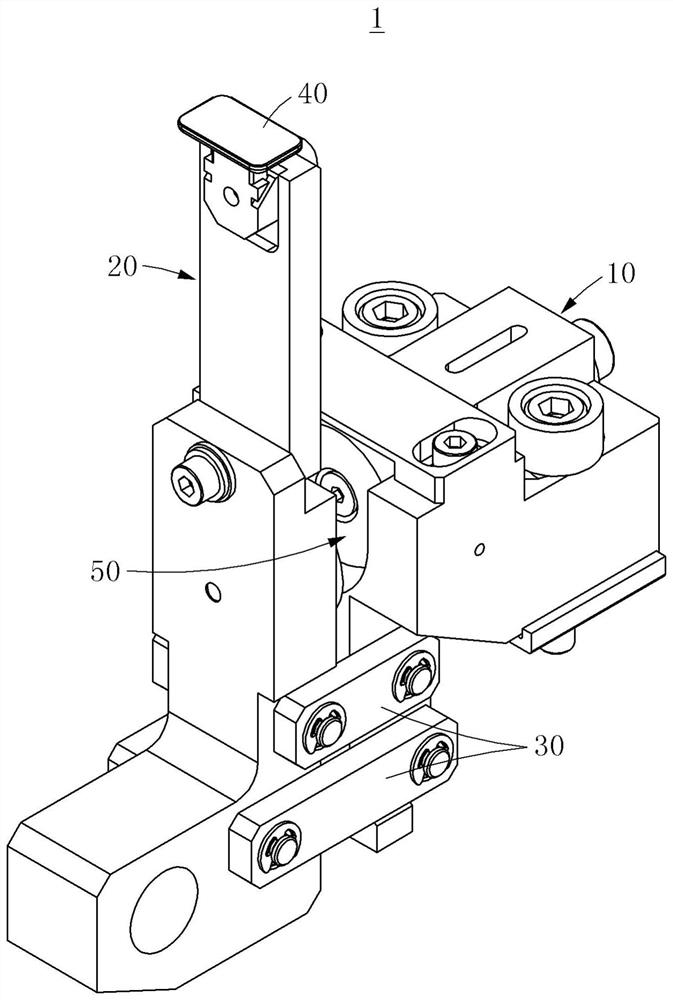

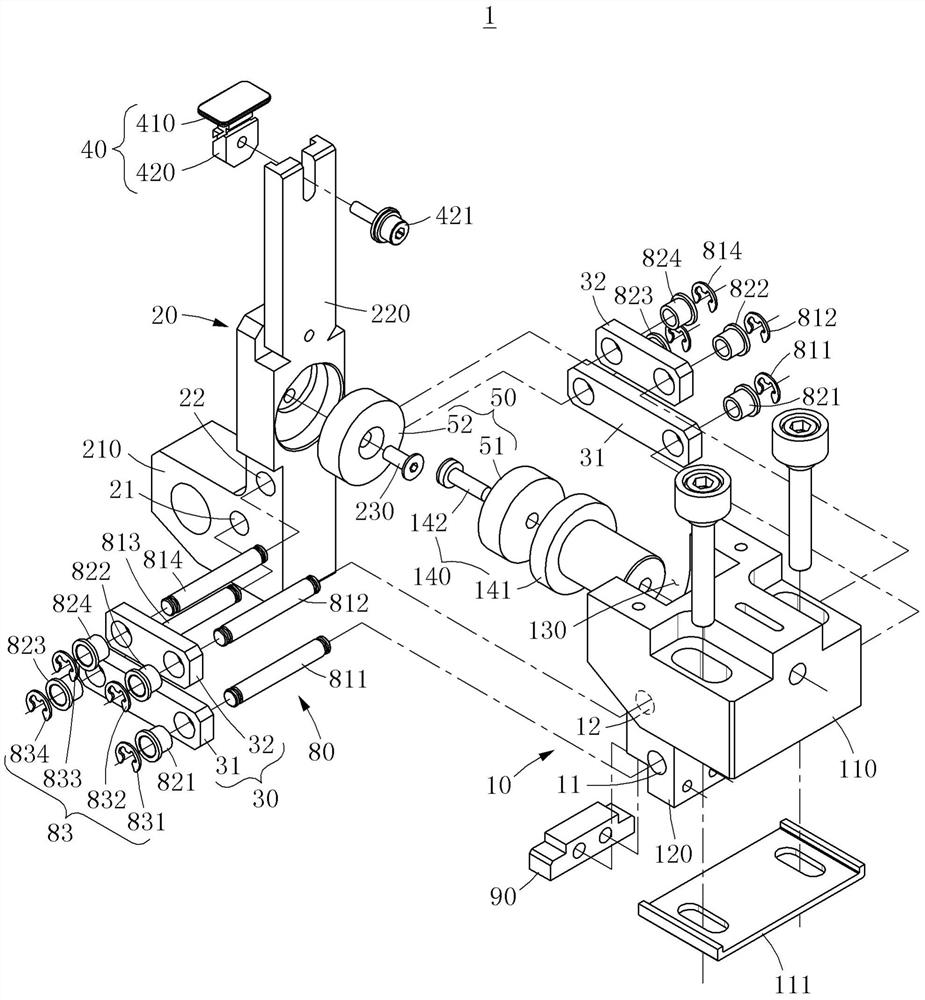

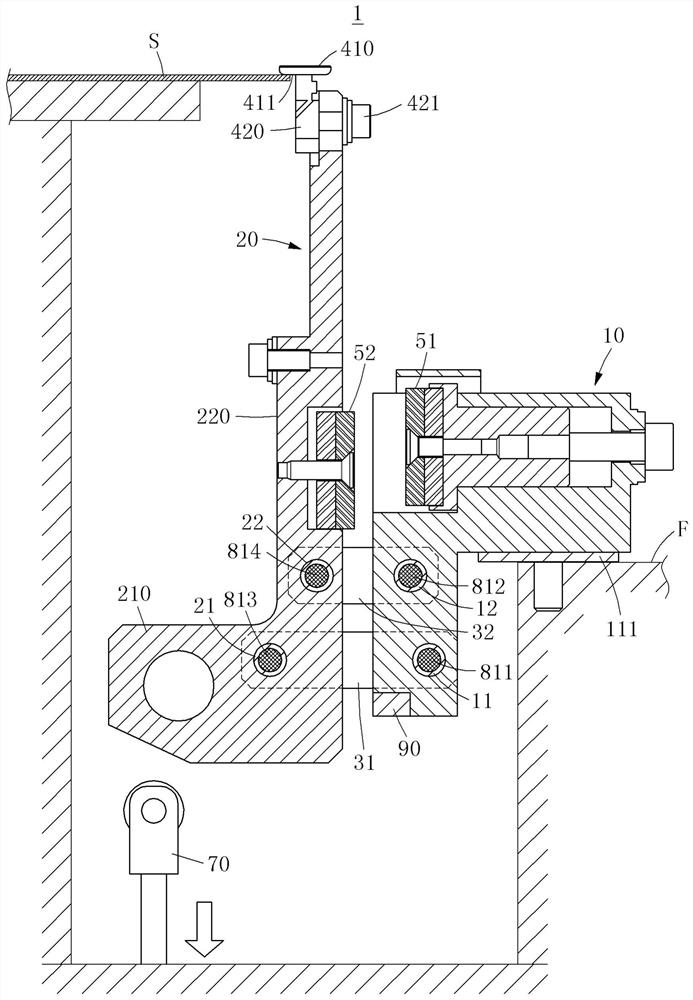

[0036] Embodiments are described in detail below with reference to exemplary drawings. Reference signs are added to structural elements in each drawing. It should be noted that the same reference signs are used as much as possible even if the same structural elements are shown in other drawings, and detailed descriptions of related known structures or functions are judged. This detailed description is omitted when it would obscure the invention.

[0037] In addition, terms such as first, second, A, B, (a), and (b) may be used when describing constituent elements of the embodiments. The term is only used to distinguish this structural element from other structural elements. The terms do not limit the nature, or the sequence or order, etc. of the corresponding structural elements. When some structural elements are described as being "linked", "combined" or "connected" to other structural elements, the structural elements may be directly connected or connected to other structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com