Automatic patrol-inspecting device for transformer substation

A substation automatic and rotating shaft technology, applied in switchgear, TV, electrical components, etc., can solve the problem of small image acquisition range, avoid shadow interference, narrow the blind area of acquisition, and ensure the quality of acquisition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

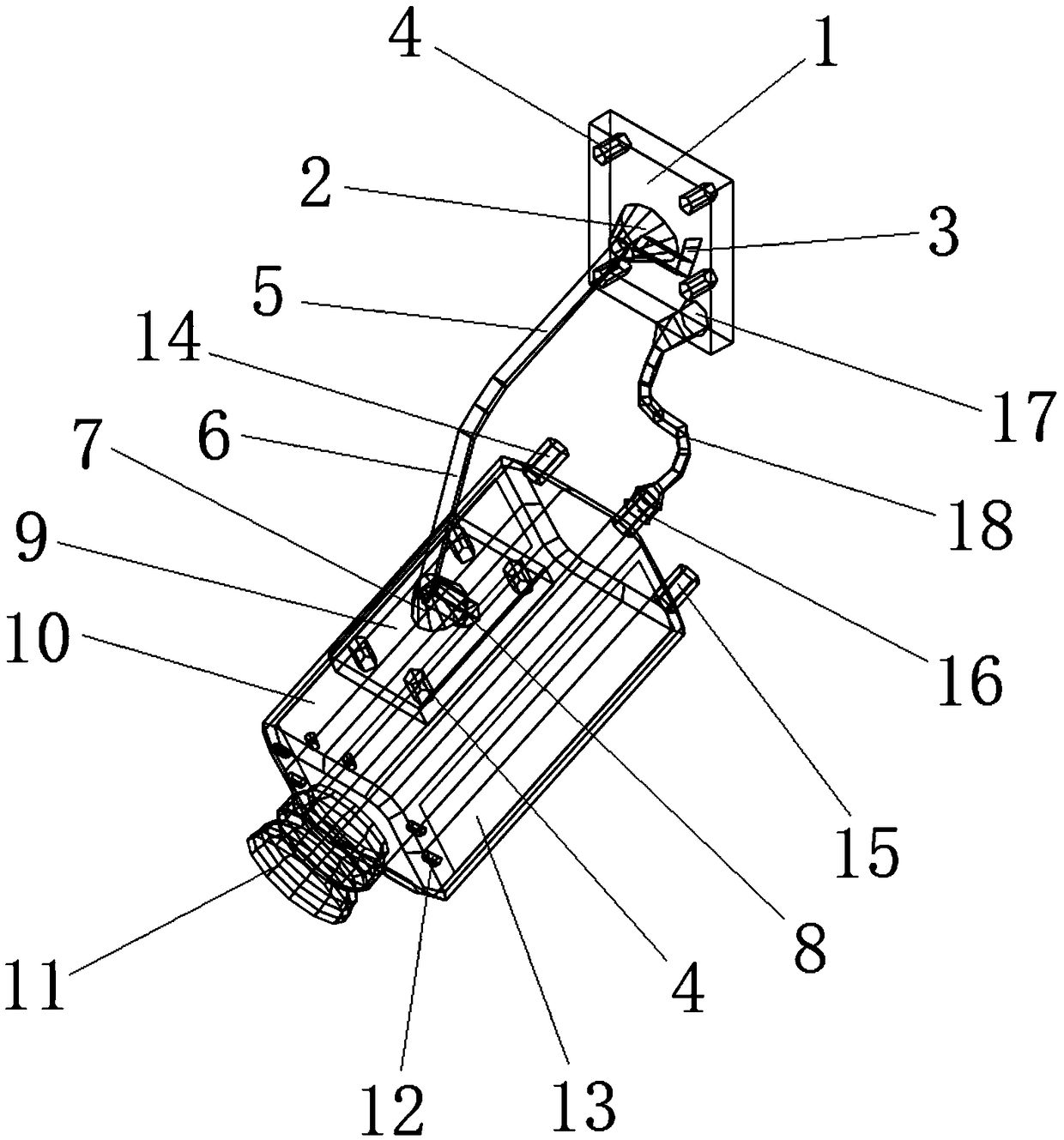

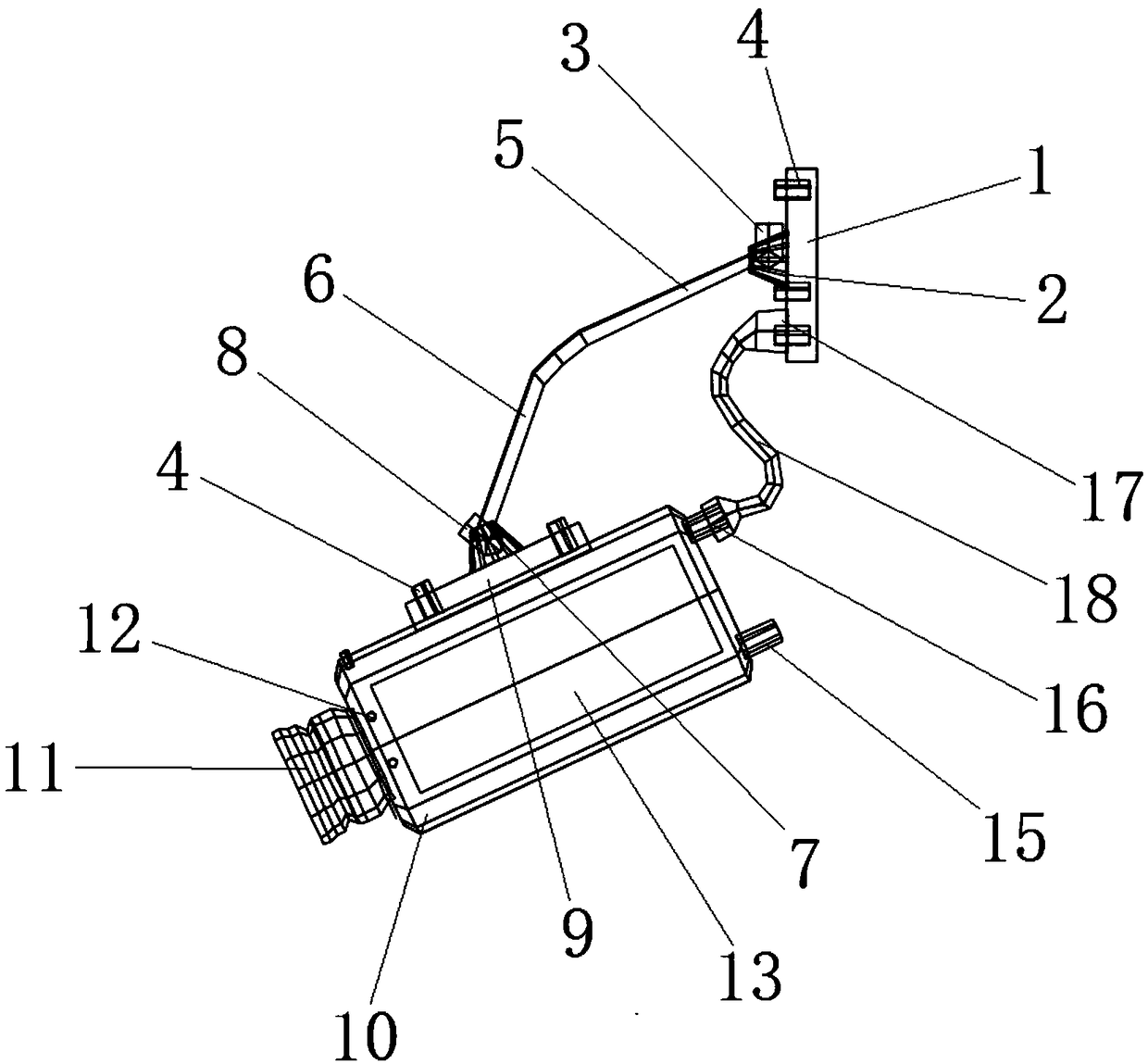

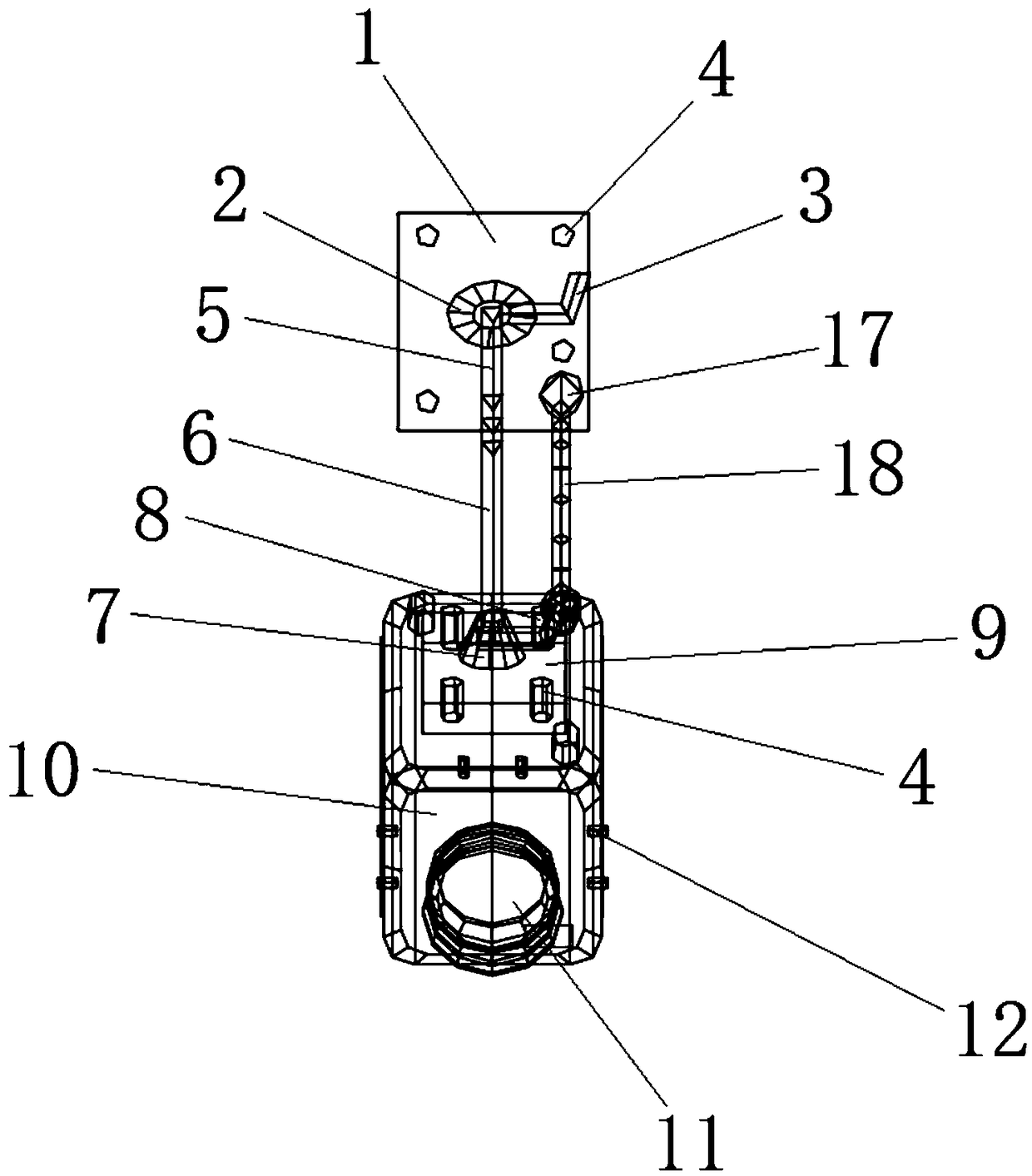

[0025] Substation automatic inspection device, such as Figure 1~3 As shown, it includes a base 1, a first rotating shaft 2, a first protruding rod 3, a bolt 4, a connecting rod 5, a bending part 6, a second rotating shaft 7, a second protruding rod 8, a connecting plate 9, a camera 10, Lens 11, supplementary light 12, panel light 13, wireless signal transmitter 14, wireless signal receiver 15, line outlet 16, threading hole 17, hose 18, wherein the first rotating shaft 2 is located on the base 1, the second A first protruding rod 3 is connected to the outer wall of a rotating shaft 2, a number of bolts 4 are connected to the base 1, a curved portion 6 is provided on the connecting rod 5, the upper end of the connecting rod 5 is connected with the first rotating shaft 2, and the curved portion 6 The lower end of the second rotating shaft 7 is connected with the second rotating shaft 7, and the second rotating shaft 7 is located on the connecting plate 9, and the outer wall of ...

Embodiment 2

[0028] Substation automatic inspection device, such as Figure 1~3 As shown, it includes a base 1, a first rotating shaft 2, a first protruding rod 3, a bolt 4, a connecting rod 5, a bending part 6, a second rotating shaft 7, a second protruding rod 8, a connecting plate 9, a camera 10, Lens 11, supplementary light 12, panel light 13, wireless signal transmitter 14, wireless signal receiver 15, line outlet 16, threading hole 17, hose 18, wherein the first rotating shaft 2 is located on the base 1, the second A first protruding rod 3 is connected to the outer wall of a rotating shaft 2, a number of bolts 4 are connected to the base 1, a curved portion 6 is provided on the connecting rod 5, the upper end of the connecting rod 5 is connected with the first rotating shaft 2, and the curved portion 6 The lower end of the second rotating shaft 7 is connected with the second rotating shaft 7, and the second rotating shaft 7 is located on the connecting plate 9, and the outer wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com