Thread delivery device and thread brake

A technology of a braking device and a yarn guide, applied in the field of yarn guides, can solve the problems of worsening the uniformity of the pressure of the brake belt, the interference of the pressure of the brake belt, the sensitivity of the yarn quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Detailed description of the preferred embodiment

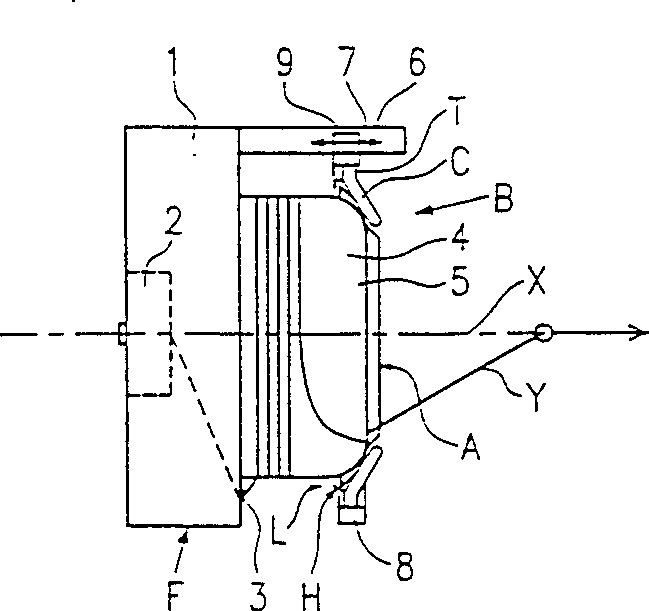

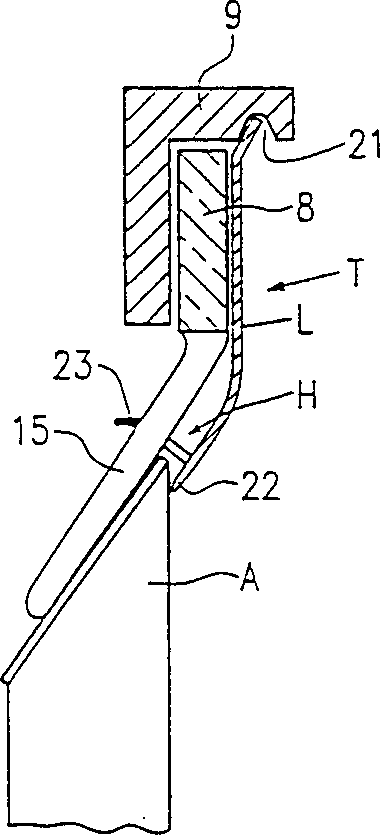

[0045] The yarn feeder F, which is equipped with a yarn braking device B, optionally forming a structural unit itself, has a drive motor 2 for the winding mechanism 3 in the housing 1 . On the housing 1 there is a drum-type yarn storage body 4 which has a circumferentially continuous circular or conical unwinding edge 5 . The yarn braking device B is fixedly supported on a support element 9 which is preferably axially adjustable in the direction of the double arrow 6 and which is mounted in the housing arm 7 . An approximately annular brake band support T is installed in the support member 9, and the brake band support T presses a circumferentially continuous brake band A generally axially (the axis X of the storage body) on the unwinding edge 5 on. The brake band is made of a wear-resistant material with a thickness between 0.01 and 1.0 mm, such as metal or metal alloy, and has the shape of a frustoconical sleeve. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com