Temperature control terminal and temperature control method

A terminal and control module technology, applied in the direction of machinery and equipment, can solve the problems that cannot be set separately, are not practical, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

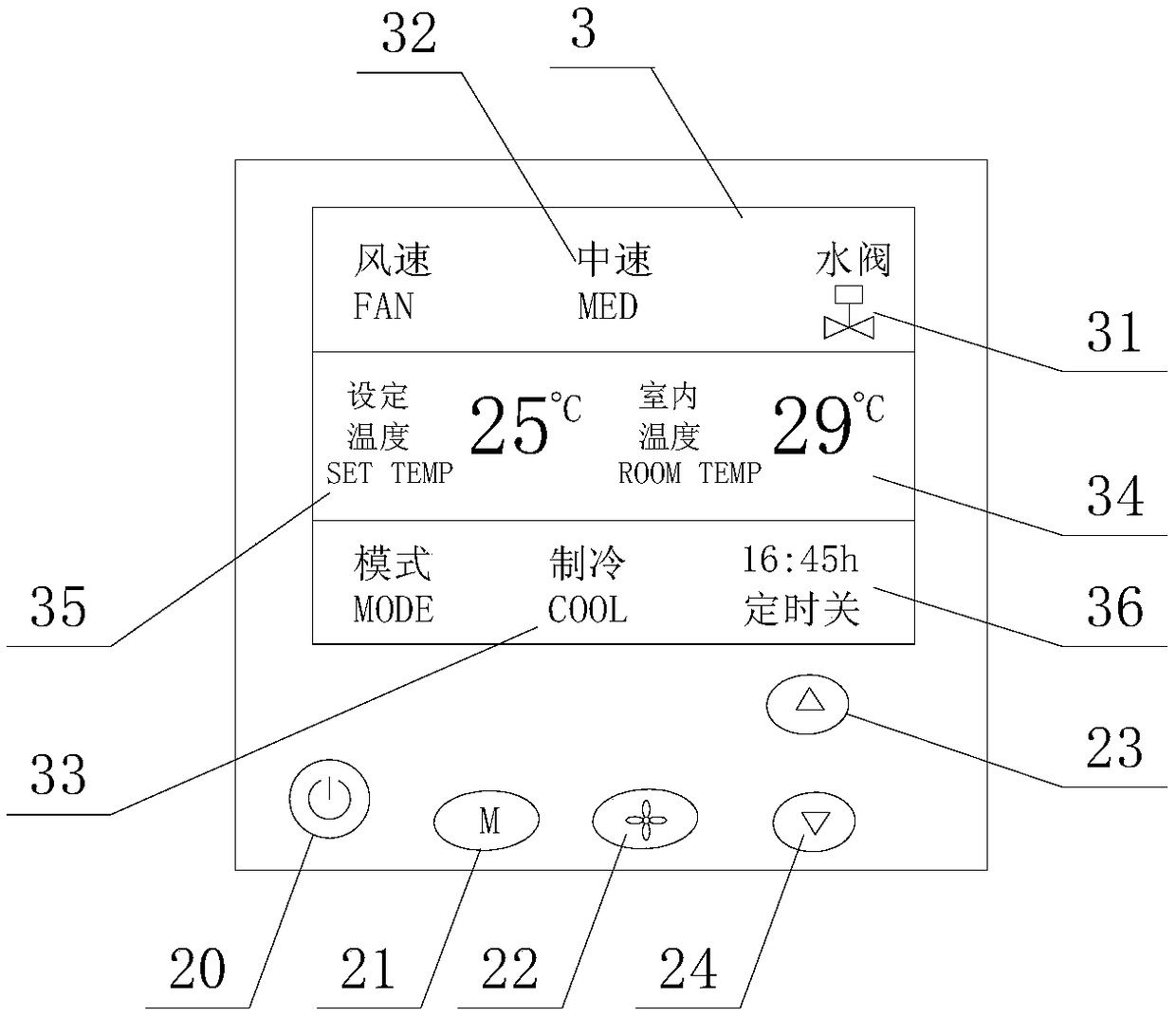

[0082] Embodiment 1: see as figure 1 , an electric valve self-cleaning device (or temperature control terminal), including a display screen, operation buttons and an output board, wherein the display screen can display operating mode 33 icons, including cooling, heating and air supply modes and wind speed icons 32, And the icons of indoor temperature 34, set temperature 35, date and time 36 and electric valve 31; The temperature control terminal can be in cooling, heating and air supply modes respectively by mode key 21.

[0083] The output module is electrically connected with the electric valve of the fan coil unit and the fan, and the electric valve includes its internal spool, and is connected with the fan coil unit through a water pipe; the electrical connection includes the direct connection of the output module with the electric valve and fan, and is directly driven by the output Electric valve and fan; it also includes the output module connected to the driving module...

Embodiment 2

[0107] The difference between embodiment 2 and embodiment 1 is that no temperature control terminal is used, the electric valve is directly electrically connected to the control center, and the electric valve is directly activated by the control center for self-cleaning.

Embodiment 3

[0108] The difference between Embodiment 3 and Embodiment 1 is that each switching action in the self-cleaning action of the electric valve adopts a positive and negative progressive type. When the control center or the control terminal drives the electric valve from closing to opening, the electric Valve opening signal, let the valve core move forward for a certain position, and then give the electric valve closing signal, the valve core moves reversely for a certain position, repeat several times, and then fully open the electric valve, and there can be a slight pause between the forward and reverse movements; And vice versa; this method is mainly suitable for electric valves with forward and reverse movement of the spool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com