Self-cleaning control terminal of electrically operated valve

A technology for controlling terminals and electric valves, applied in the direction of mechanical equipment, etc., can solve problems such as lower cost performance, electric valves stuck or closed tightly, and unsatisfactory effects, and achieve good self-cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

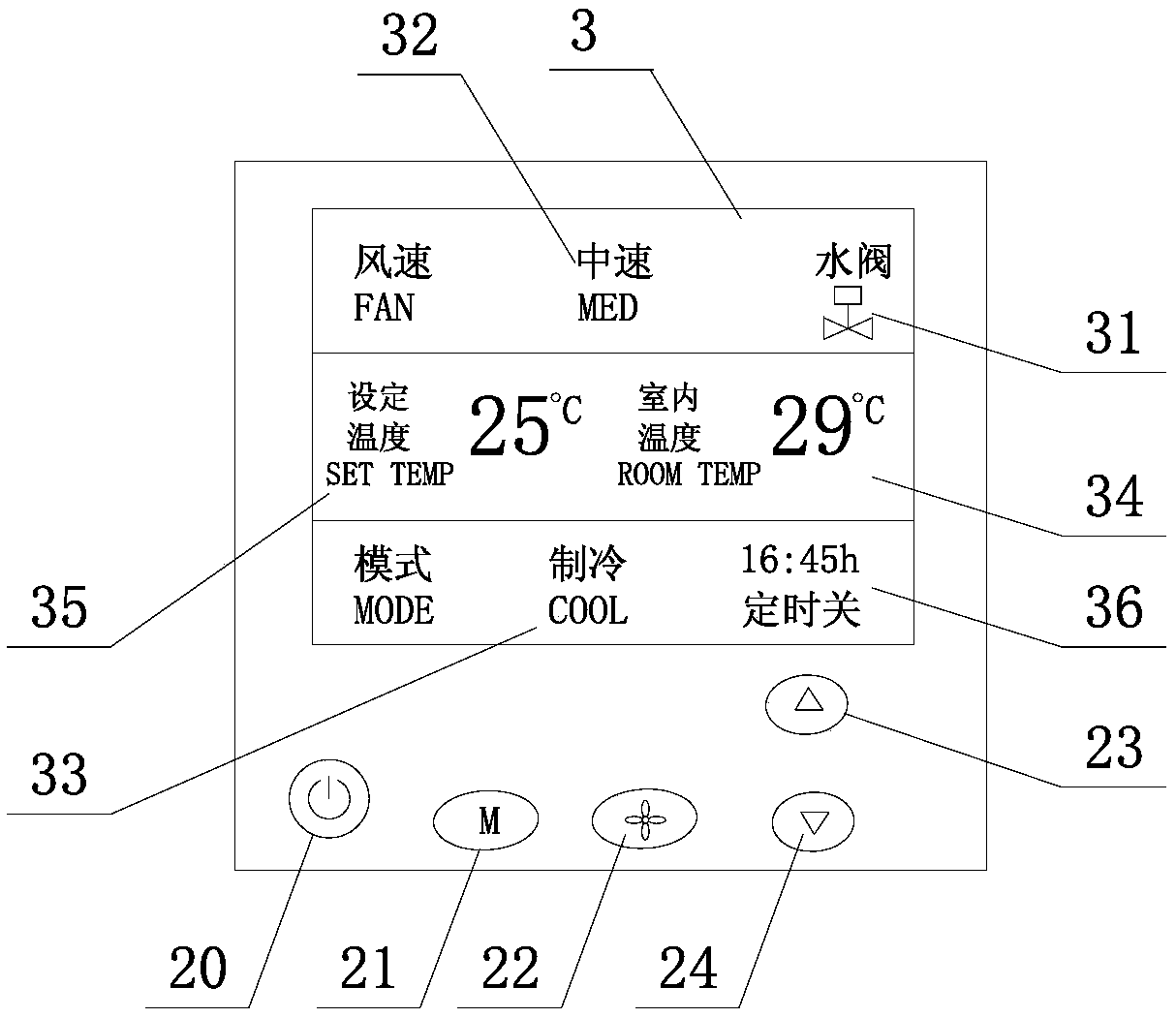

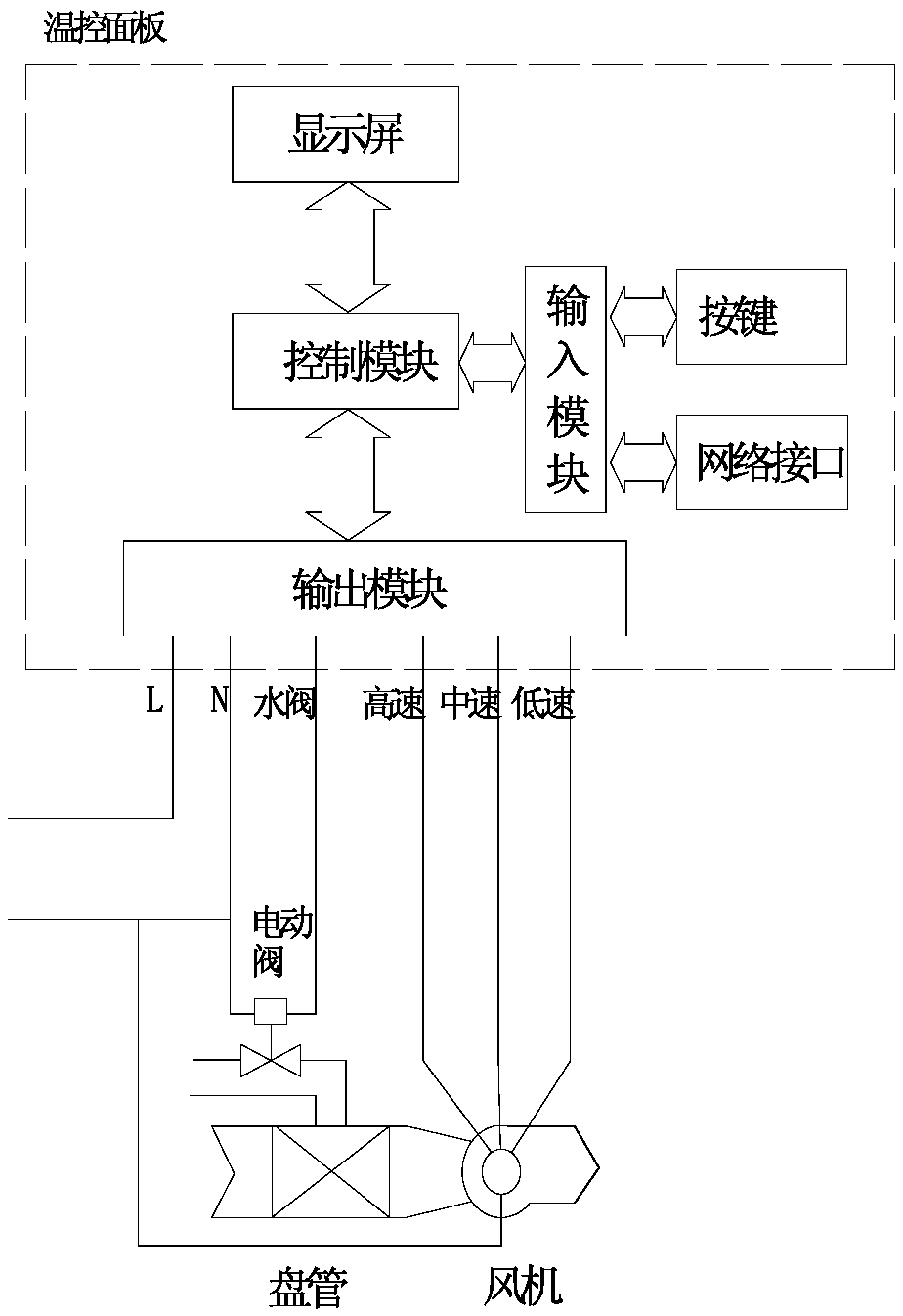

[0075] see as figure 1 and figure 2 , the electric valve flexible controller is a temperature control panel of a fan coil unit, including a display screen, operation buttons and an output board, wherein the display screen can display 33 icons of operating modes, including cooling, heating and air supply modes and wind speed icons 32 , and the icons of indoor temperature 34, set temperature 35, date and time, and electric valve; wherein the operation keys include switch key 20, mode key 21, wind speed key 22, increase key 23, and decrease key 24. Through the mode key 21, the temperature control panel can be respectively in cooling mode, heating mode and air supply mode.

[0076] The output module is electrically connected with the electric valve of the fan coil unit and the fan, and the electric valve includes its internal spool, and is connected with the fan coil unit through a water pipe; the electrical connection includes the direct connection of the output module with the...

Embodiment 2

[0095] The difference from Embodiment 1 is that, on the basis of the existing functions of the temperature control panel, the flexible action function of the electric valve is added.

[0096] The switching action of the electric valve driven by the temperature control panel includes a flexible switching method. In addition to the conventional direct switch, the electric valve also has a flexible switching method; that is, the opening of the electric valve is opened in a flexible manner, or the electric valve is closed in a flexible manner. Shut down, or the opening and closing of the electric valve adopts a flexible method; or each action of the electric valve uses a flexible switch method, or only uses a flexible switch method for a specific part of the electric valve. The electric valve is different from the solenoid valve, and the switching action time is generally more than ten seconds, which makes it possible to realize the flexible switch. Among them, the flexible action...

Embodiment 3

[0114] The difference from Embodiment 1 is that, on the basis of the existing functions of the temperature control panel, a temperature locking function that can lock the lowest cooling value and the highest heating value is added.

[0115] After the administrator locks the cooling minimum value under the temperature lock function, when the user adjusts the set temperature in the cooling mode, the set temperature will not decrease after reaching the locked cooling minimum value. After the administrator locks the maximum heating value under the temperature lock function, when the user adjusts the set temperature in the heating mode, the set temperature will not rise after reaching the maximum locked heating value, so that the internal program of the temperature control panel Prevent users from setting the temperature too low or too high.

[0116] Further, the parameter setting of the locked temperature function can be entered through any key combination operation on the tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com