Sand mold casting sand screening machine

A technology of sand casting and sand screening machine, which is applied in the direction of casting molding equipment, cleaning/processing machinery of casting mold materials, manufacturing tools, etc., which can solve the problems of low efficiency and poor screening effect, so as to avoid splashing and structure Simple and practical, with high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

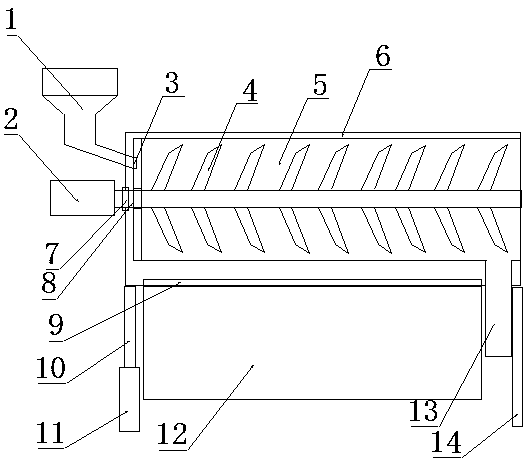

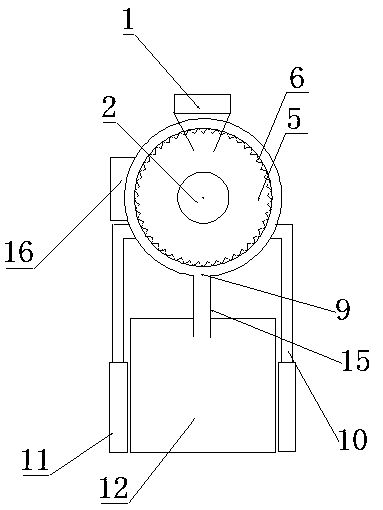

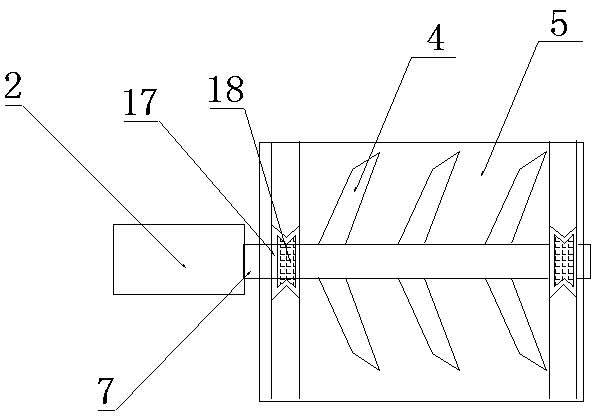

[0018] Such as Figure 1-3 As shown, a sand casting sand screening machine includes an inner screen cylinder 5 and an outer cylinder 6, an outer cylinder 6 is provided on the outside of the inner screen cylinder 5, and a control panel 16 is provided on the side of the outer cylinder 6 , the lower part of the outer cylinder 6 is provided with a front leg and a rear leg 14, the front leg is composed of a piston rod 10 and a hydraulic cylinder 11, and the rear leg 14 is hinged at the bottom of the outer cylinder 6 , the bottom of the outer cylinder 6 is provided with a sand outlet 9, the sand outlet 9 is provided with a sand control plate 15, and the bottom of the described sand control plate 15 is provided with a sand collection tank 12, and the described The front of the inner screen cylinder 5 is welded with a feed port 1, the junction of the feed port 1 and the inner screen drum 5 is provided with a solenoid valve 3, and a motor 2 is provided below the feed port 1. The motor...

Embodiment 2

[0021] Such as Figure 1-3 As shown, a sand casting sand screening machine includes an inner screen cylinder 5 and an outer cylinder 6, an outer cylinder 6 is provided on the outside of the inner screen cylinder 5, and a control panel 16 is provided on the side of the outer cylinder 6 , the lower part of the outer cylinder 6 is provided with a front leg and a rear leg 14, the front leg is composed of a piston rod 10 and a hydraulic cylinder 11, and the rear leg 14 is hinged at the bottom of the outer cylinder 6 , the bottom of the outer cylinder 6 is provided with a sand outlet 9, the sand outlet 9 is provided with a sand control plate 15, and the bottom of the described sand control plate 15 is provided with a sand collection tank 12, and the described The front of the inner screen cylinder 5 is welded with a feed port 1, the junction of the feed port 1 and the inner screen drum 5 is provided with a solenoid valve 3, and a motor 2 is provided below the feed port 1. The motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com