Preparation method for composite aerogel thermoelectric material

A technology of composite airgel and thermoelectric materials, which is applied in the field of preparation of composite airgel thermoelectric materials, can solve the problems of airgel electrical conductivity decrease and thermal conductivity increase, and achieve abundant raw materials, improved electrical conductivity, and production process Simple and convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

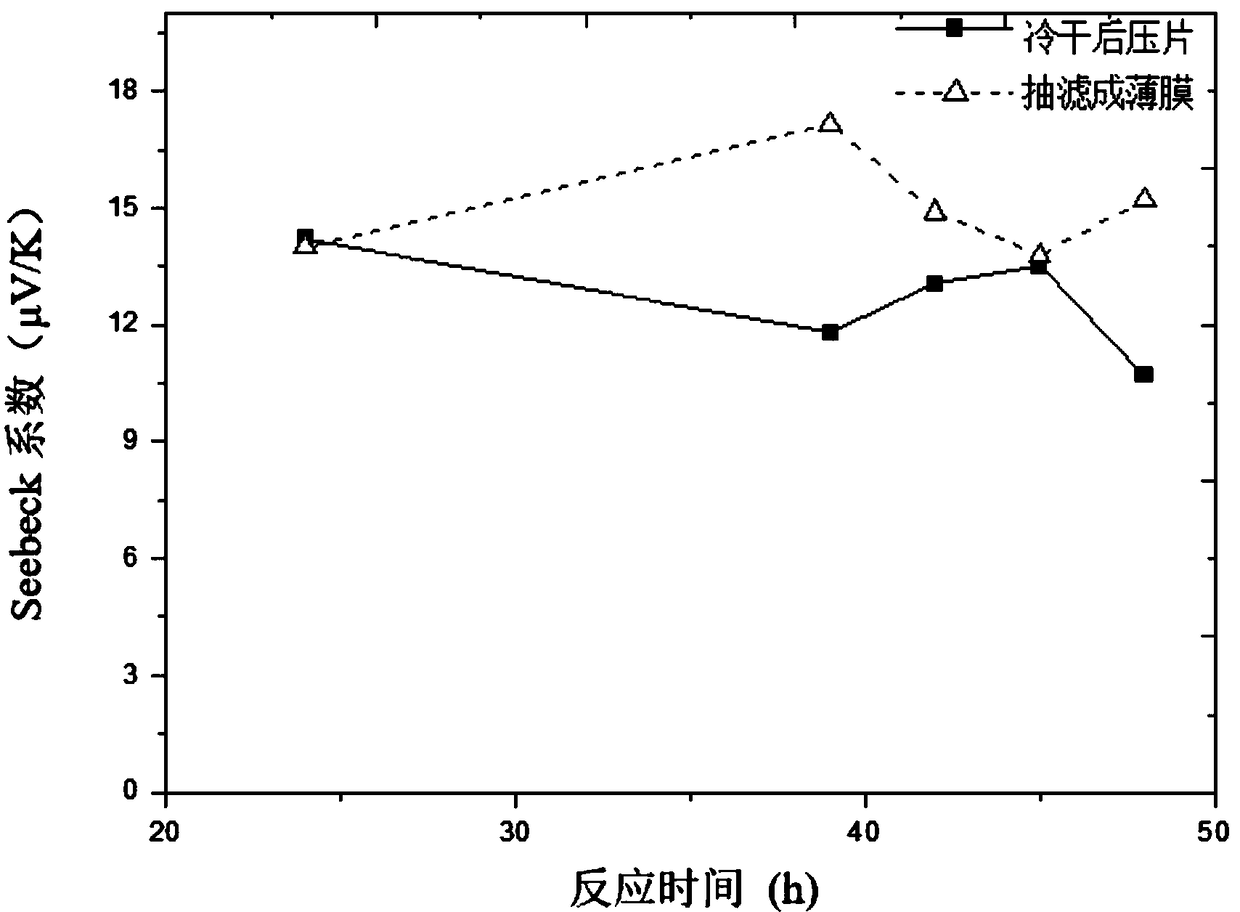

Examples

Embodiment 1

[0023] (1) Preparation of composite material mixture: Dilute 10ml (2mg / ml) of bacterial cellulose with 20ml of deionized water, then mix it with 1.27mmol of EDOT monomer in the aqueous solution, add 1.35mmol of nonaqueous water and nitric acid after fully stirring The aqueous solution made of iron and 3ml of deionized water was fully stirred for 24 hours, washed with HCL (0.1mol / L) and deionized water for at least 3 times, and finally made into a composite material mixture with a concentration of 2mg / ml.

[0024] (2) Preparation of airgel: the obtained solution was frozen at -50° C. for 4 hours, and then vacuum freeze-dried for 48 hours to obtain an airgel.

[0025] (3) Treatment of airgel: use a powder tablet press at 5 MPa and 50°C for 15 minutes to obtain a BC-PEDOT multi-component composite sheet with a porous structure.

Embodiment 2

[0027] (1) Preparation of composite material mixture: Dilute 10ml (2mg / ml) of bacterial cellulose with 20ml of deionized water, then mix it with 1.27mmol of EDOT monomer in the aqueous solution, add 1.35mmol of nonaqueous water and nitric acid after fully stirring The aqueous solution made of iron and 3ml of deionized water was fully stirred for 24 hours, washed with HCL (0.1mol / L) and deionized water for at least 3 times, and finally made into a composite material mixture with a concentration of 2mg / ml.

[0028] (2) Preparation of airgel: mix (1) solution with different proportions of DWCNT, stir, and sonicate. The obtained solution was frozen at -10°C for 4 hours, and then vacuum freeze-dried for 48 hours to obtain an airgel.

[0029] (3) Treatment of airgel: use a powder tablet press at 50 MPa and 0°C for 0.1 min to obtain a BC-PEDOT multi-component composite sheet with a porous structure.

Embodiment 3

[0031] (1) Preparation of composite material mixture: Dilute 10ml (2mg / ml) of bacterial cellulose with 20ml of deionized water, then mix it with 1.41mmol of EDOT monomer in the aqueous solution, add 2.43mmol of nonaqueous water and nitric acid after fully stirring The aqueous solution made of iron and 3ml of deionized water was fully stirred for 36 hours, and HCL (0.1mol / L) and deionized water were used for 3 times respectively, and finally a composite material mixture solution with a concentration of 2mg / ml was prepared.

[0032] (2) Preparation of airgel: Mix the solution of (1) with different proportions of MWNT, stir and sonicate. The obtained solution was frozen at -30°C for 4 hours, and then vacuum freeze-dried for 48 hours to obtain an airgel.

[0033] (3) Treatment of airgel: use a powder tablet press at 25 MPa and 50° C. for 10 minutes to obtain a BC-PEDOT multi-component composite sheet with a porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com