A kind of manufacturing method of one-time molded plastic-encapsulated photocoupler

A technology of optocoupler and manufacturing method, which is applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve problems such as difficult problems, high cost and process, achieve enhanced reflection effect, accurately adjust transmission delay, and improve photoelectric coupling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The patent will be described in further detail below in conjunction with the accompanying drawings, which is an explanation of the present invention rather than a limitation.

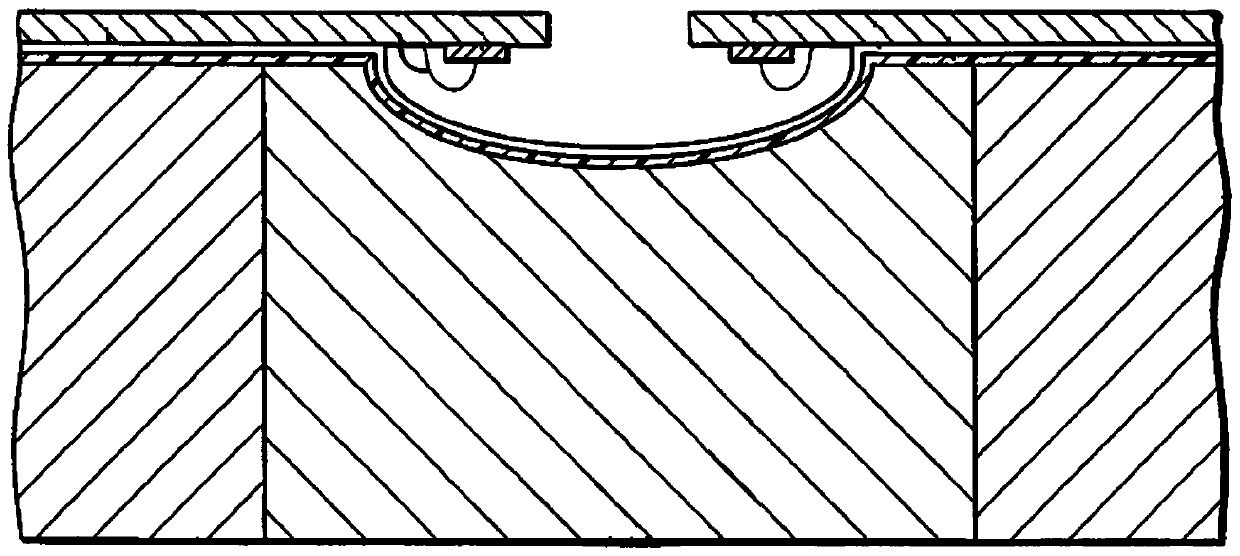

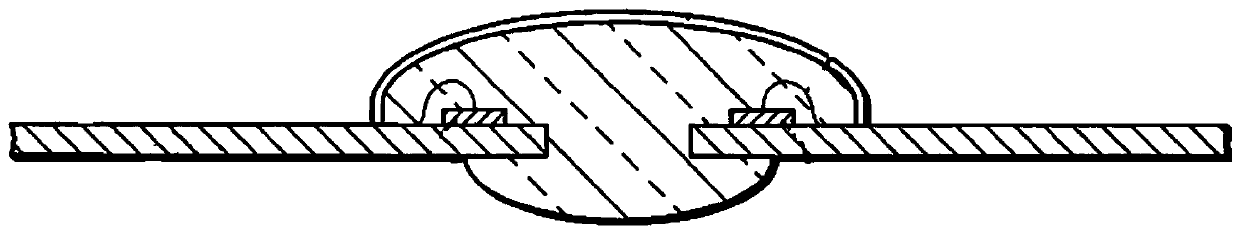

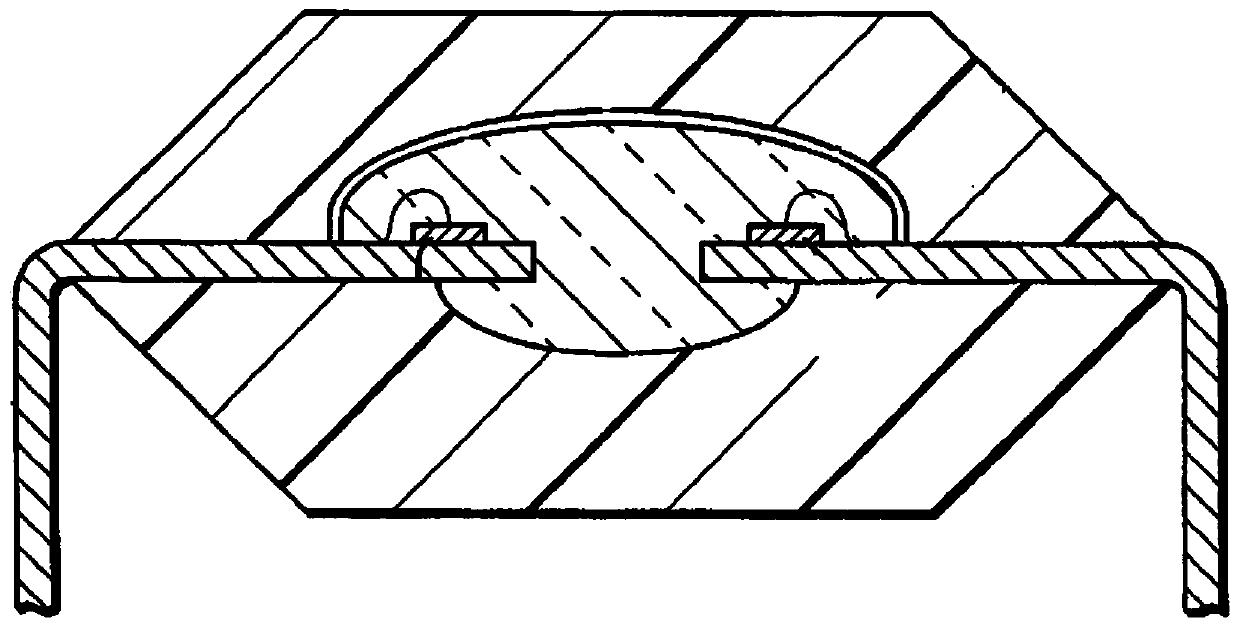

[0042] The traditional coplanar plastic-encapsulated optocoupler adopts multiple molding technology, and the manufacturing process is as follows: Figure 1 ~ Figure 3as shown, figure 1 To make the optical coupler photoconductive medium forming mold for this process, first use conductive glue to bond the light-emitting chip and light-receiving chip of the photocoupler on the surface of the gold island of the tube leg of the metal lead frame, and bond the wire to make the chip and the gold island An electrical connection is formed, and the two gold islands are separated by a certain distance to form electrical isolation. After the photoconductive medium is injected and cured, turn over the photoconductive medium forming mold to form figure 2 The form of the semi-finished product is shown, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com