A light-driven vibration motor device based on optical fiber

A vibration motor and light-driven technology, applied in the field of optical fiber micro-nano technology research, can solve the problems of difficult capture of absorbing particles and few researches on absorbing particles, and achieve the effect of simple preparation method, simple structure and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

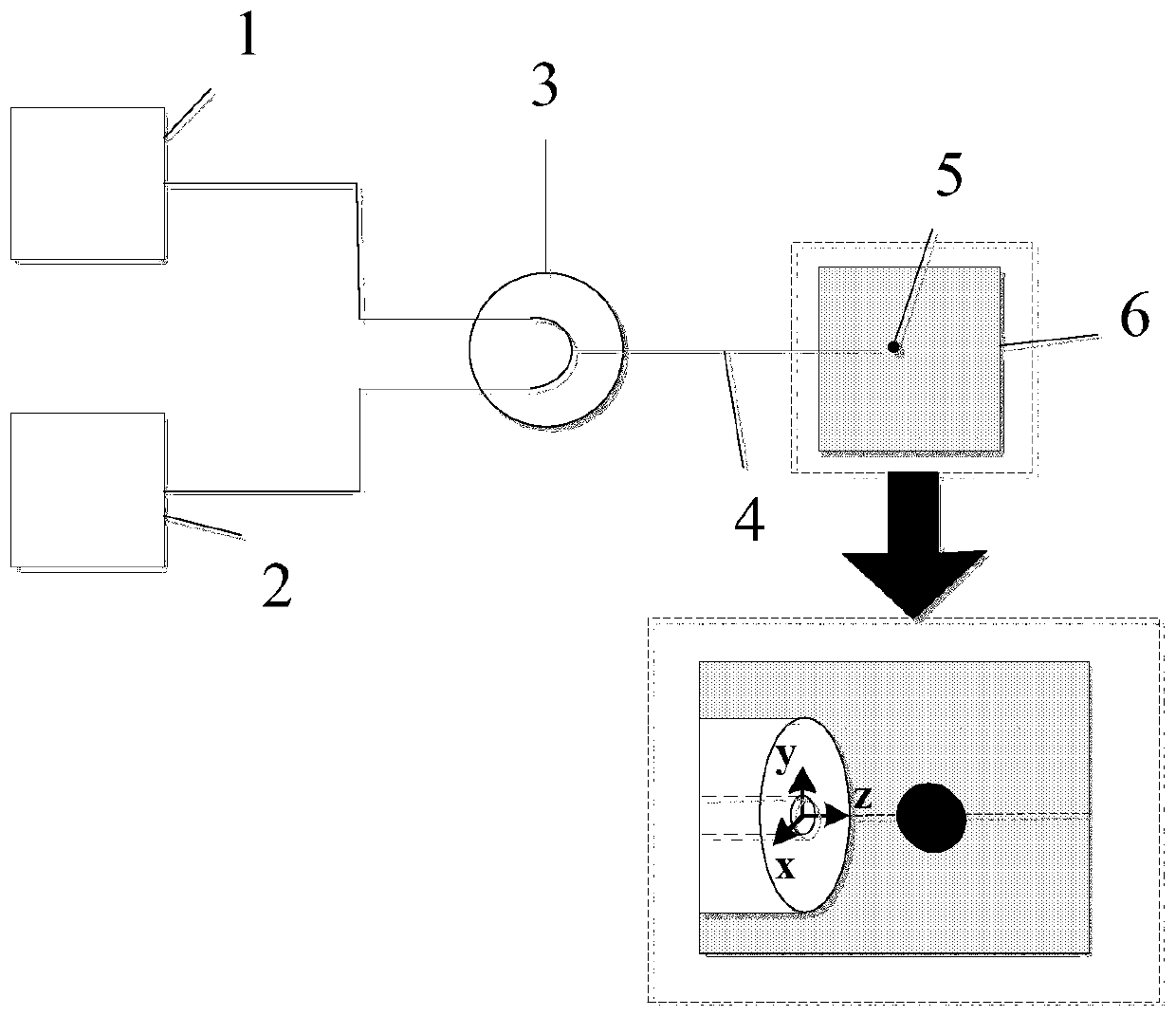

[0036] Such as image 3 As shown, a light-driven vibration motor based on optical fiber includes a first optical fiber light source 1, a second optical fiber light source 2, a 980nm-1550nm optical fiber wavelength division multiplexer 3, a 980nm single-mode optical fiber 4, and a 6 μm absorbing black ball 5 , Glycerin 6.

[0037] 1. Take a section of single-mode optical fiber 4 with a length of about 1 meter. Strip off the coating layer of the optical fiber at one end of the single-mode optical fiber 4 for 20-30mm. Use a non-woven cloth to dip in a mixture of alcohol and ether, and wipe the outer cladding of the optical fiber repeatedly. until cleaned and ready for use;

[0038] 2. Cut the end face of the cleaned single-mode optical fiber 4 flat with an optical fiber cutter;

[0039] 3, use the method in steps 1 and 2 to the laser first optical fiber light source 1 of 980nm wavelength, the second optical fiber light source 2 of 1550nm wavelength laser and the pigtail of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com