Method and device for anomaly monitoring of power plant production subsystem based on two-stage clustering

An anomaly monitoring and subsystem technology, applied in the direction of electrical digital data processing, instruments, data processing applications, etc., can solve the problems of low fault repetition frequency, many types of faults, and difficulty in establishing an expert experience database, etc., to achieve easy expansion and reduce abnormalities The effect of false alarm rate and small influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principles of the present invention.

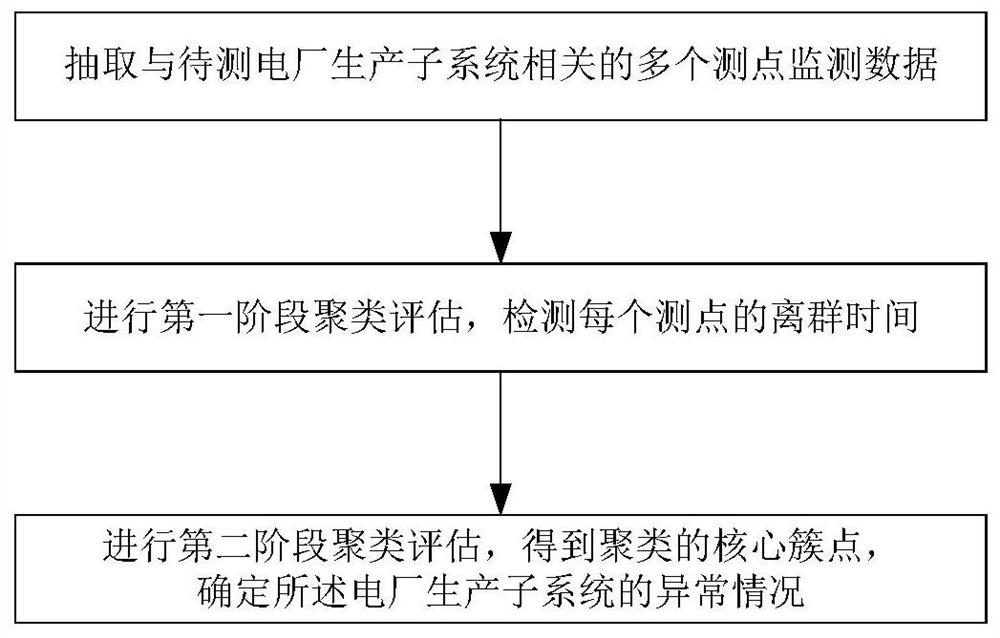

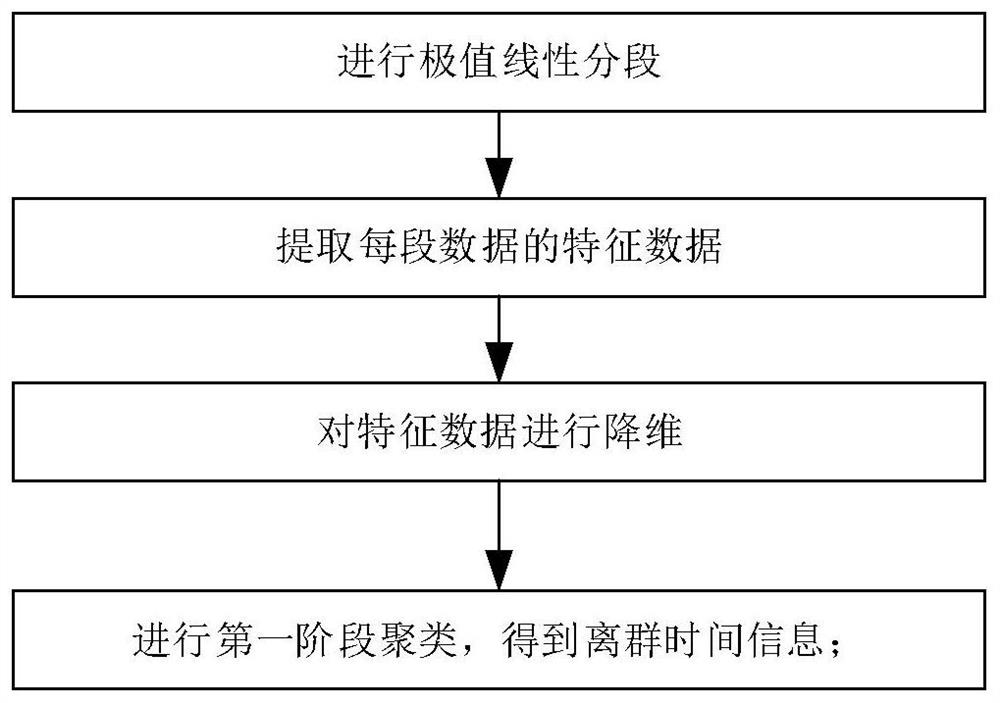

[0059] The embodiment of the present invention discloses a two-stage clustering-based abnormality monitoring method for the production subsystem of a power plant, such as figure 1 shown, including the following steps:

[0060] Step S1, extract the monitoring data of multiple measuring points related to the production subsystem of the power plant to be tested, and obtain the time data sequence of each measuring point;

[0061] Specifically include:

[0062] 1) Establish a connection with the pi database of the sis system of the power plant through authorization;

[0063] The measurement point monitoring data of this embodiment is obtained by accessing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com