Method for calibrating focal planes of OPC and PWOPC models

A focal plane and focal plane technology, applied in the field of calibrating the focal plane of OPC and PWOPC models, can solve the problems of difficult to use manufacturing, the model cannot make accurate predictions, the fluctuation of process parameters, etc., to avoid time loss, avoid company Effects of reputation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

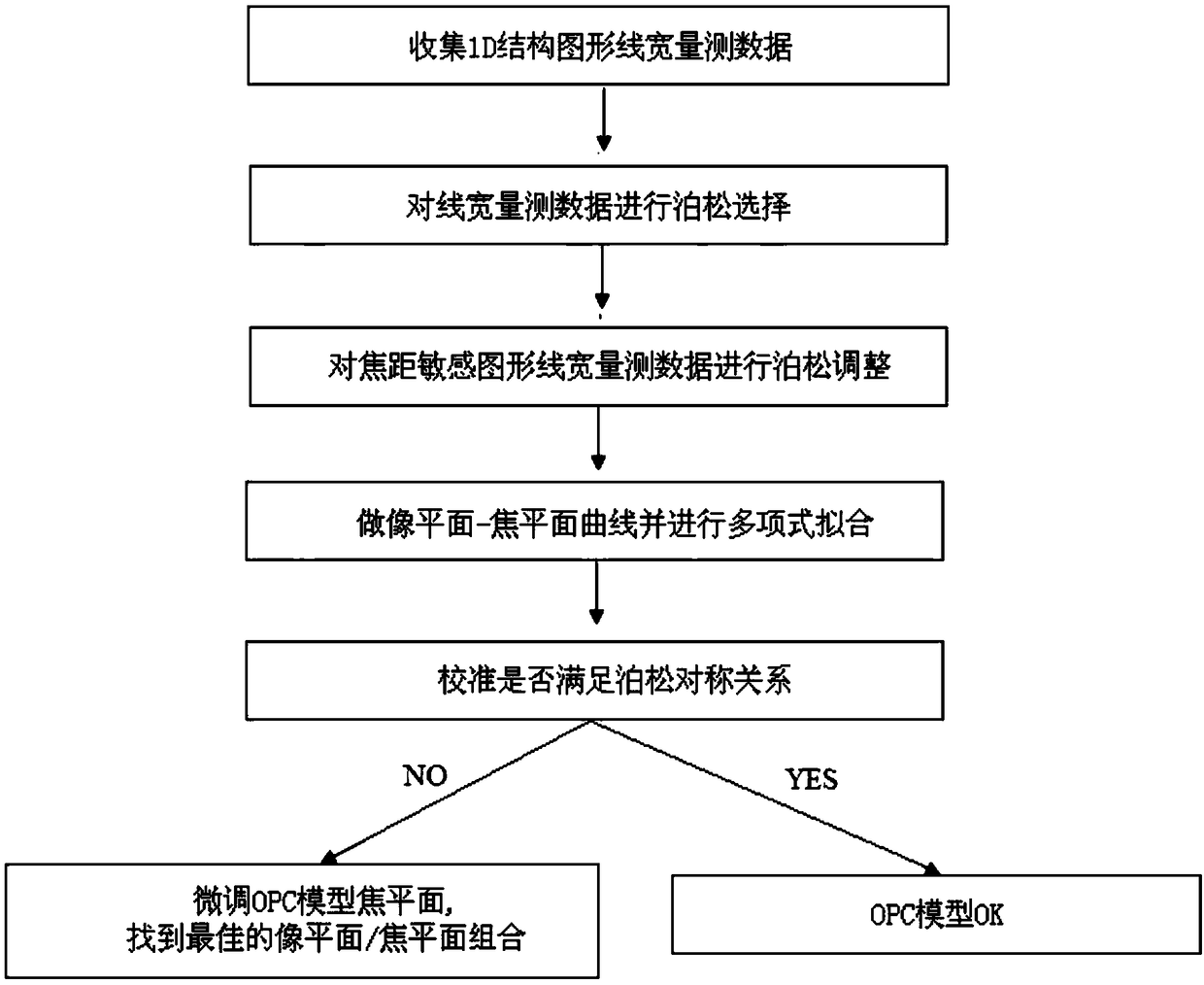

[0021] combine figure 1 Shown, the method for described calibration OPC and PWOPC model focal plane comprises the following steps:

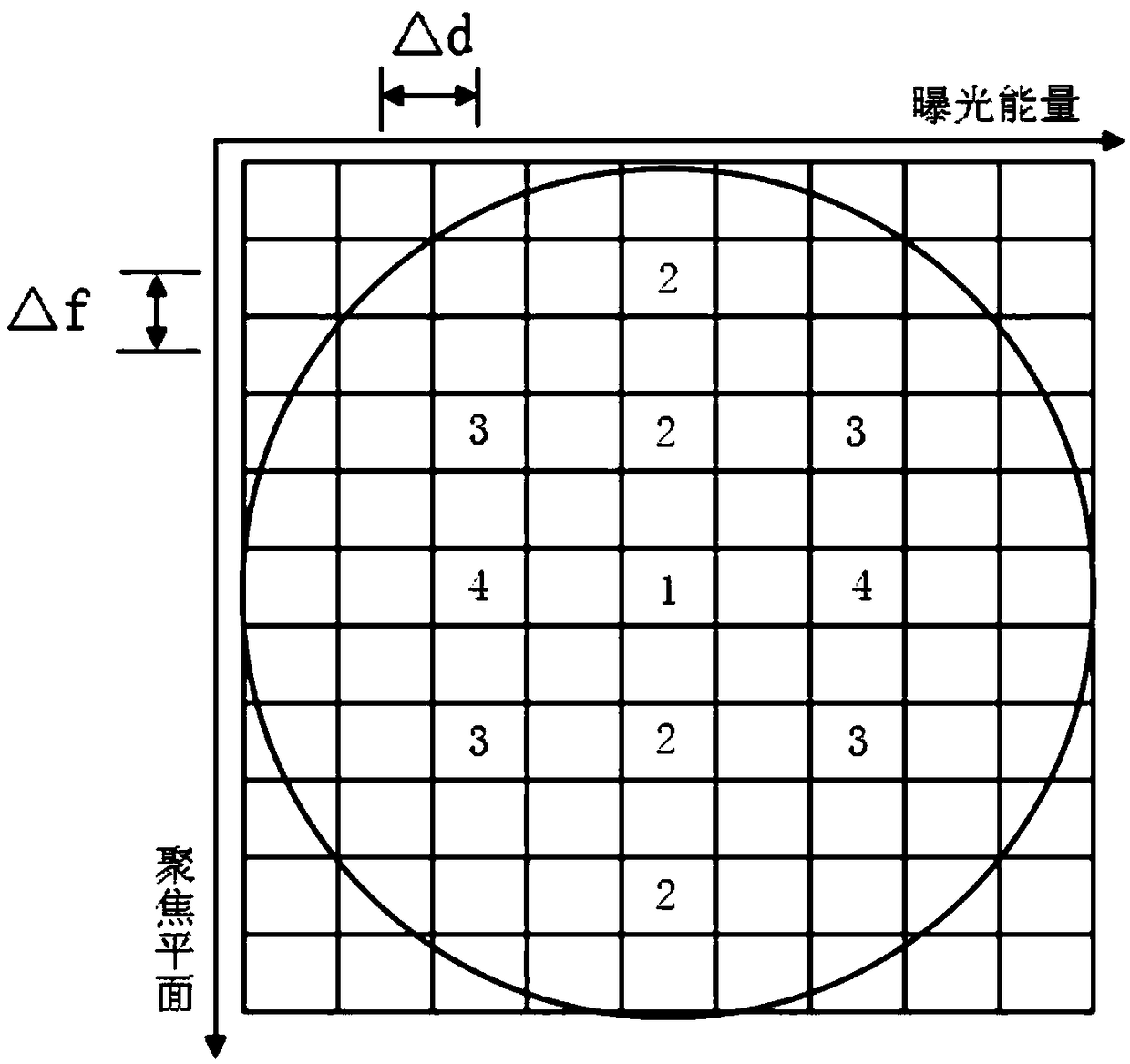

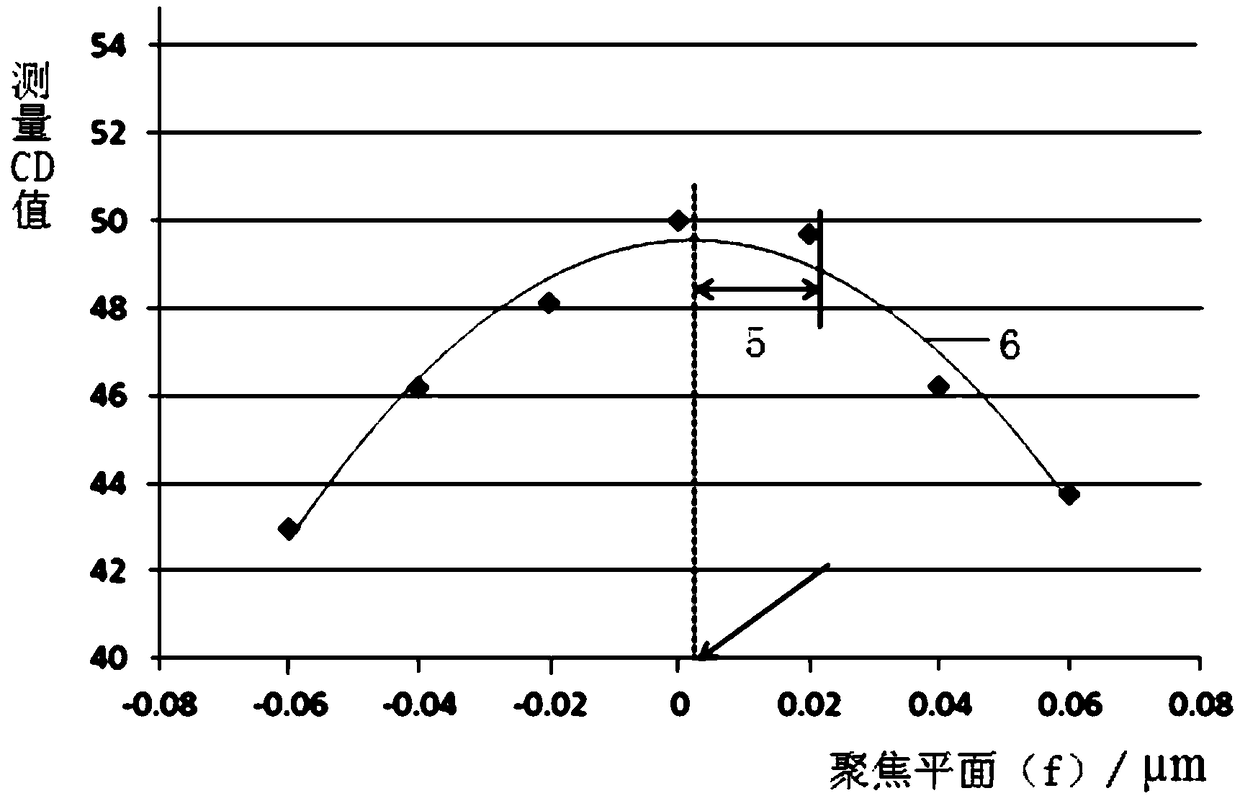

[0022] Step 1. Combine image 3 As shown, the line width measurement data under different combinations of exposure energy deviation and focal plane deviation are collected on the FEM wafer: because it is necessary to collect data under multiple deviations from the standard conditions, it is impossible to build a standard strip like Select thousands of graphics like the OPC model. Since two-dimensional structure (2D) graphics have poor outline, large roughness, and large measurement error under non-standard conditions, one-dimensional structure (1D) graphics are preferred for line width measurement, and the line width of the selected graphics should be Try to cover the line width stipulated in the device design rules of the process, and the line width of the 1D structure graphics should at least cover the range of the minimum line width*±20% sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com