Preparation method of hydrogen peroxide non-enzymatic sensor based on laser-induced graphene-precious metal nanocomposite

A nanocomposite, laser-induced technology, applied in the direction of instruments, scientific instruments, material excitation analysis, etc., can solve the problems of affecting catalyst performance and cumbersome steps, and achieve the effect of low material cost, broad application prospects, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

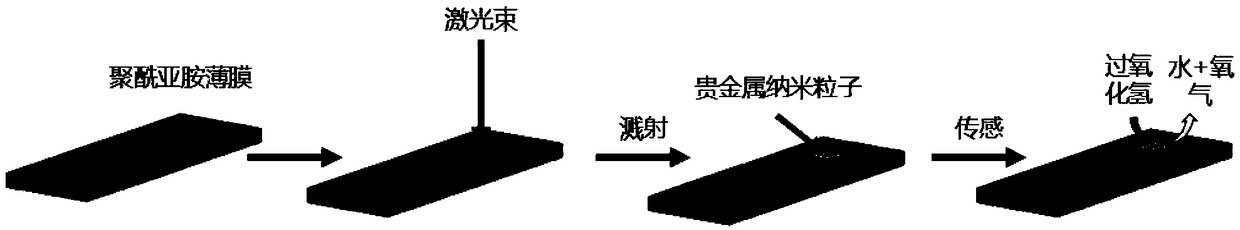

[0025] (1) Use CorelDRAW software to design electrode patterns according to actual needs;

[0026] (2) According to the designed electrode pattern, use a high-intensity laser beam to engrave or burn on the surface of a 25 μm polyimide film to form a multi-layer graphene foam structure, and remove the remaining material of the polyimide film, which is patterning laser-induced graphene;

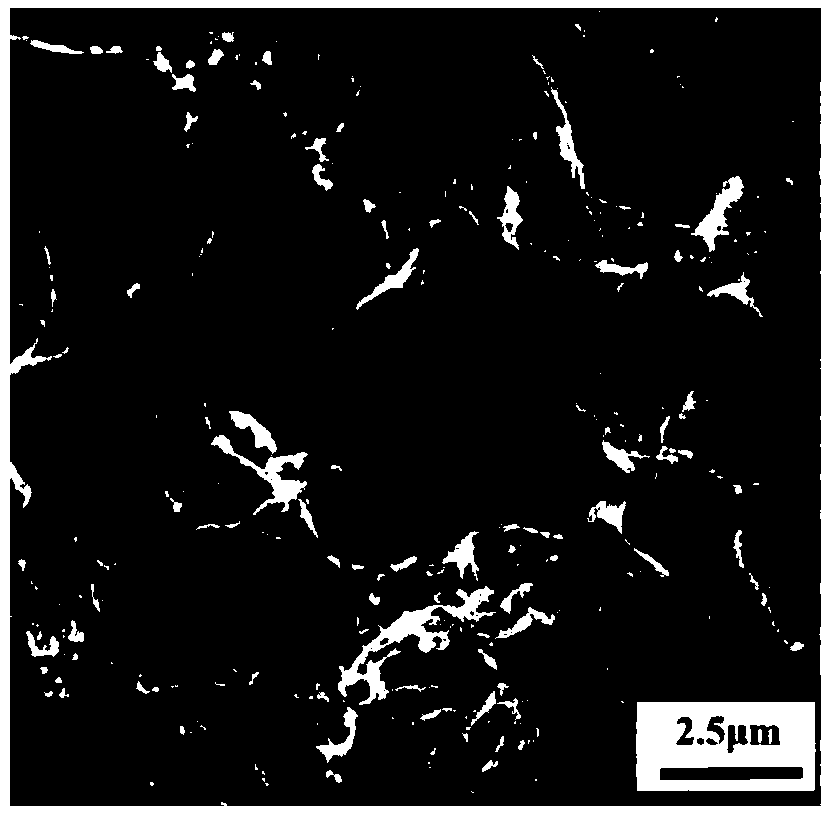

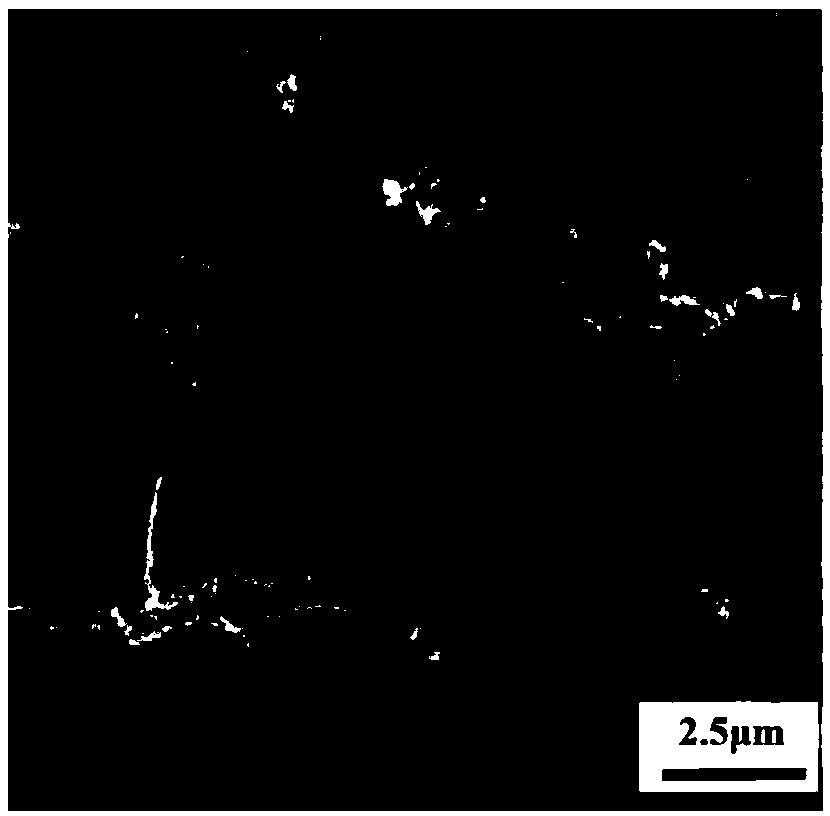

[0027] (3) Synthesis of laser-induced graphene-platinum nanocomposites: move the laser-induced graphene into a vacuum magnetron sputtering device for platinum sputtering with a thickness of 10nm to manufacture platinum-laser-induced graphene nanocomposites; The sputtering process parameters are: sputtering pressure 0.5Pa, sputtering power 30W, and sputtering temperature 20°C.

[0028] (4) Using the laser-induced graphene-platinum nanocomposite as the working electrode, together with the auxiliary electrode and the reference electrode, an electrochemical sensor for hydrogen peroxide is formed. ...

Embodiment 2

[0045] (1) Design the electrode pattern with CorelDRAW software;

[0046] (2) According to the designed electrode pattern, use a high-intensity laser beam to engrave or burn on the surface of a 50 μm polyimide film to form a multi-layer graphene foam structure, and remove the remaining material of the polyimide film, which is patterned Laser-induced graphene;

[0047] (3) Synthesis of laser-induced graphene-gold nanocomposites: move the laser-induced graphene into a vacuum magnetron sputtering device for gold sputtering with a thickness of 15nm to manufacture gold-laser-induced graphene nanocomposites; The sputtering process parameters are: sputtering pressure 0.6Pa, sputtering power 35W, sputtering temperature 25°C.

[0048] (4) Using the laser-induced graphene-gold nanocomposite as the working electrode, together with the auxiliary electrode and the reference electrode, an electrochemical sensor for hydrogen peroxide was formed.

[0049] Specifically, step (3) preparation ...

Embodiment 3

[0051] (1) Design the electrode pattern with CorelDRAW software;

[0052] (2) According to the designed electrode pattern, use a high-intensity laser beam to engrave or burn on the surface of the 280 μm polyimide film to form a multi-layer graphene foam structure, and remove the remaining material of the polyimide film, which is patterned Laser-induced graphene;

[0053] (3) Synthesis of laser-induced graphene-silver nanocomposites: move the laser-induced graphene into a vacuum magnetron sputtering device for silver sputtering with a thickness of 25nm to manufacture laser-induced graphene-silver nanocomposites; The sputtering process parameters are: sputtering pressure 0.7Pa, sputtering power 40W, sputtering temperature 30°C.

[0054] (4) Using the laser-induced graphene-silver nanocomposite as the working electrode, together with the auxiliary electrode and the reference electrode, an electrochemical sensor for hydrogen peroxide is formed.

[0055] Specifically, step (3) pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com