Method for testing elasticity modulus of nano thin film on flexible substrate

A flexible substrate, elastic modulus technology, applied in the application of stable tension/pressure to test material strength, measuring device, strength characteristics, etc., can solve problems such as insufficient research and lack of experimental testing methods for nanofilm elastic modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

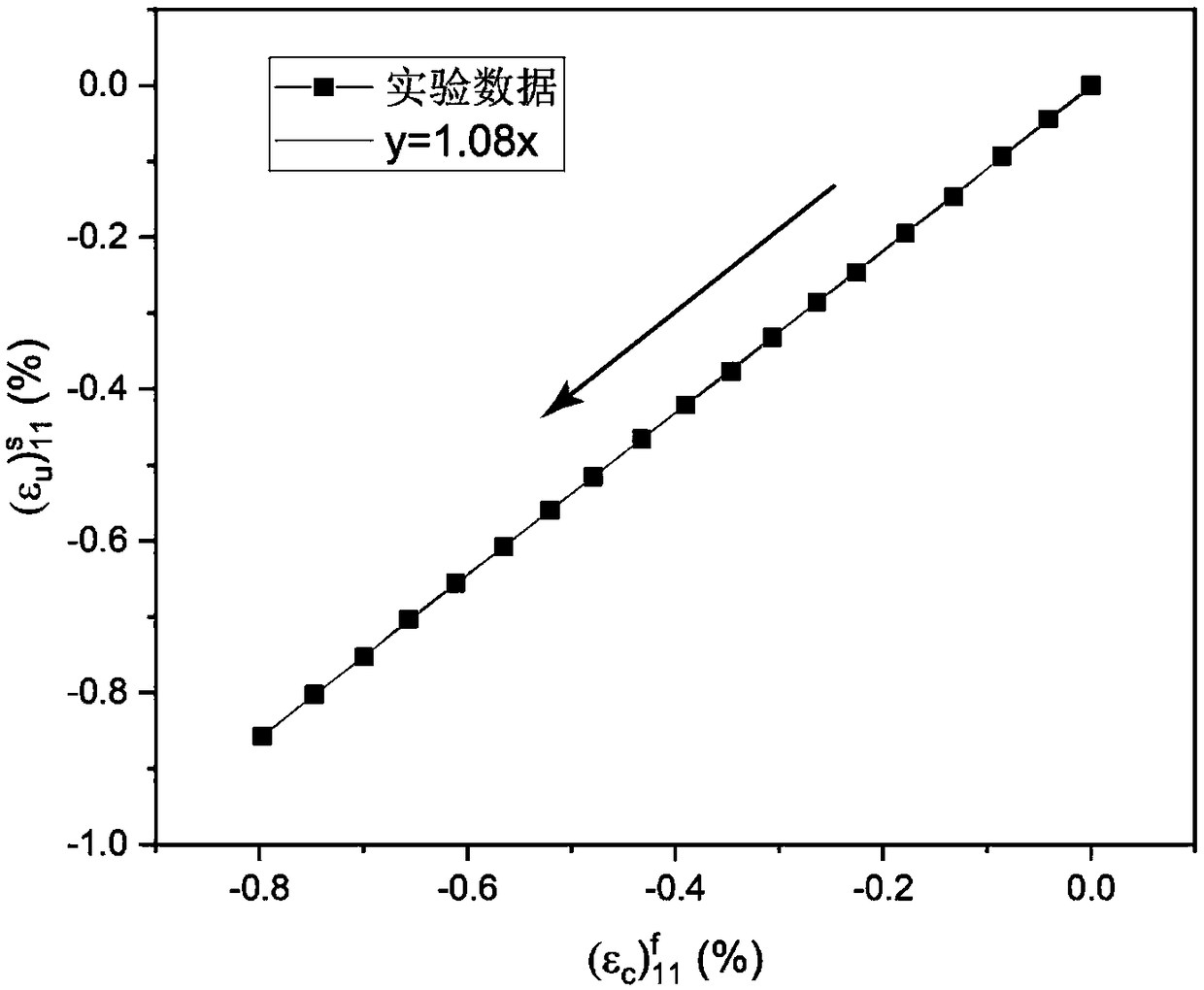

[0022] The elastic modulus testing method of the nano film on the flexible substrate that the present invention proposes, comprises the following steps:

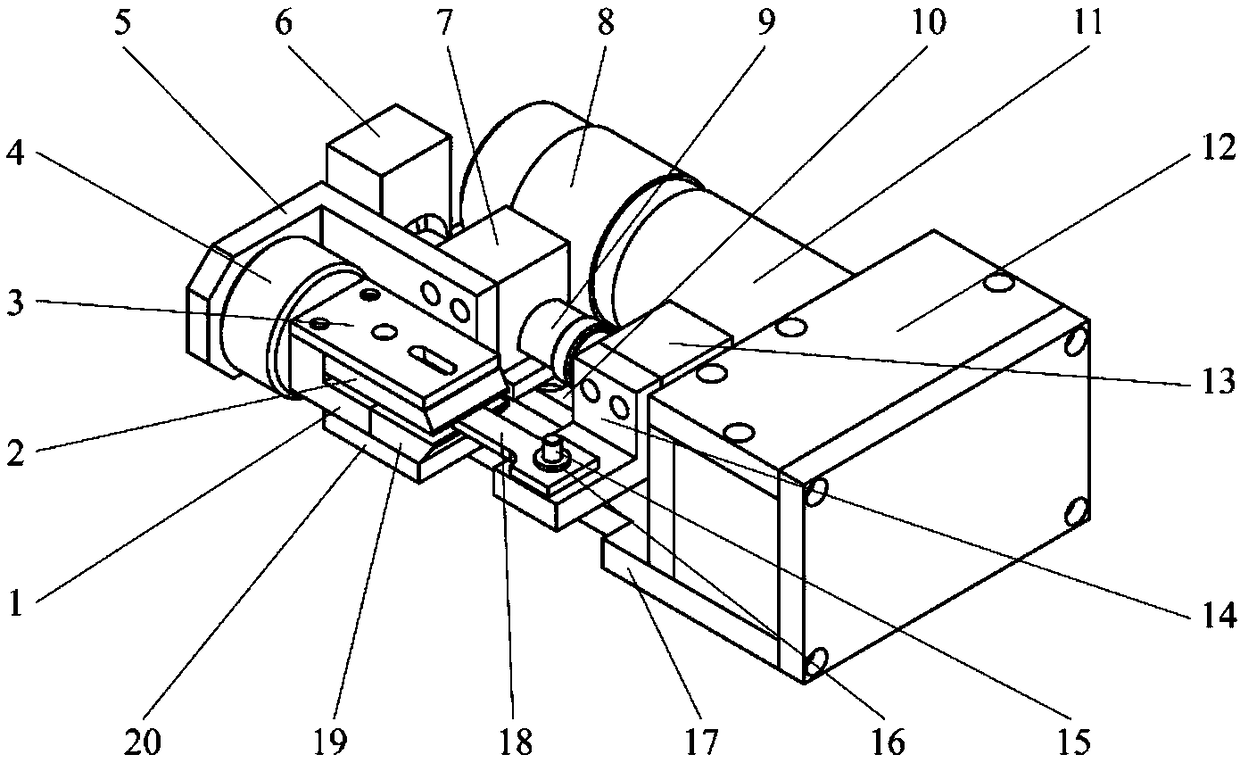

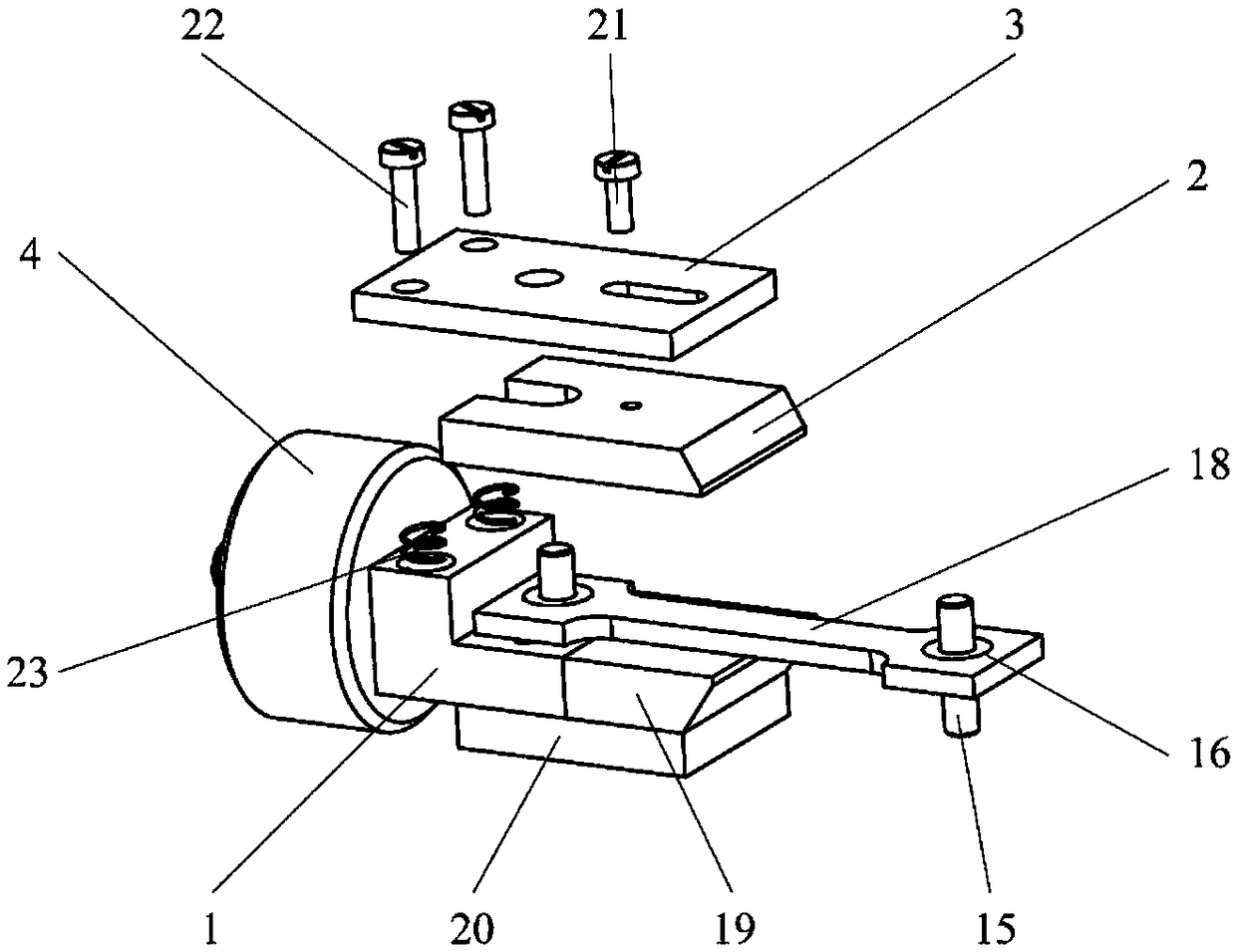

[0023] (1) Build a modulus of elasticity test device, its structure is as follows figure 1 with figure 2 As shown, the testing device includes a moving mechanism and a testing mechanism. The motion mechanism includes a stepper motor 8, a primary reducer 11, a secondary reducer 12, a ball screw 9, a left lead screw nut 7 and a right lead screw nut 13. The stepper motor 8 is installed on the base 17, the output shaft of the stepper motor 8 is connected with the primary reducer 11 and the secondary reducer 12 in turn, the secondary reducer 12 is connected with the ball screw 9, and the left screw nut 7 Linkage with the right lead screw nut 13 and the ball screw 9, the two ends of the ball screw 9 are supported in the support seat 6, and the support seat 6 is fixed on the base 17. The test mechanism includes a flexible base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com