Microchannel reactor, and method for preparing N-alkoxyoxalyl alaninate by using microchannel reactor

A technology of alkoxy oxalylalanine ester and microchannel reactor, which is applied in chemical instruments and methods, chemical/physical/physicochemical reactors, carboxylic acid amide preparation, etc., which can solve the problem of low production efficiency and poor operation Complexity, low product yield, etc., to avoid product loss, simple post-processing, and shorten the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

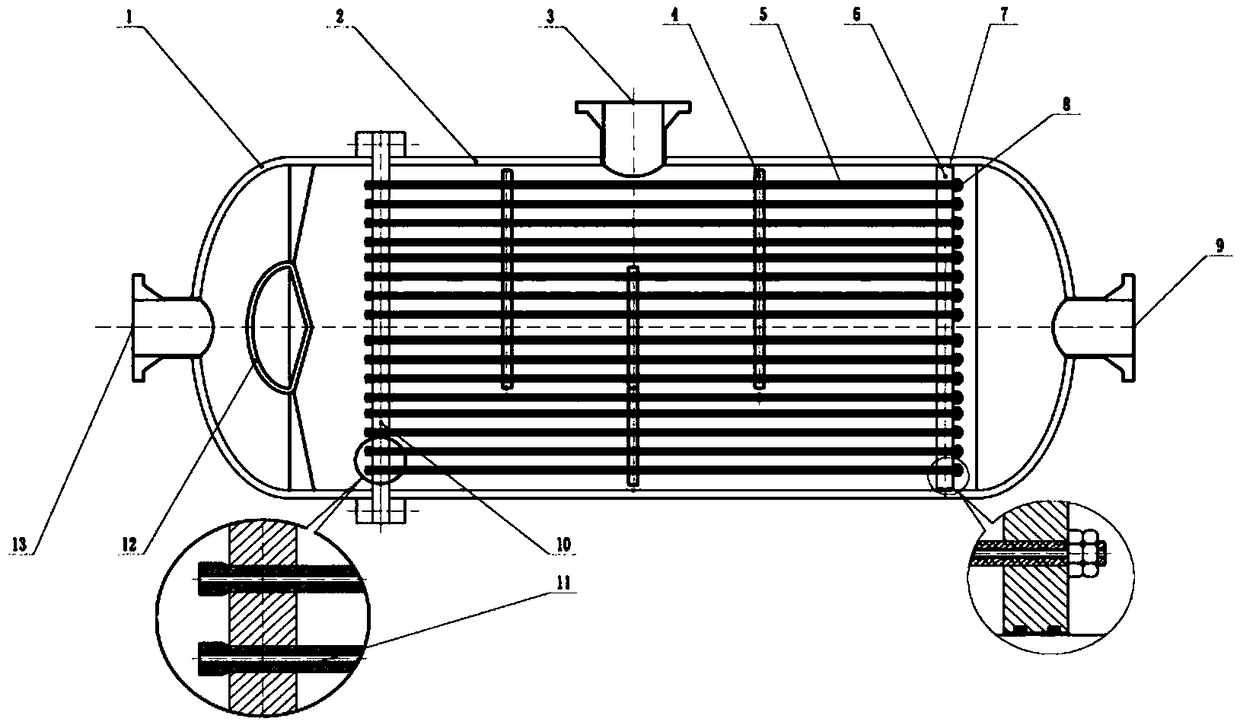

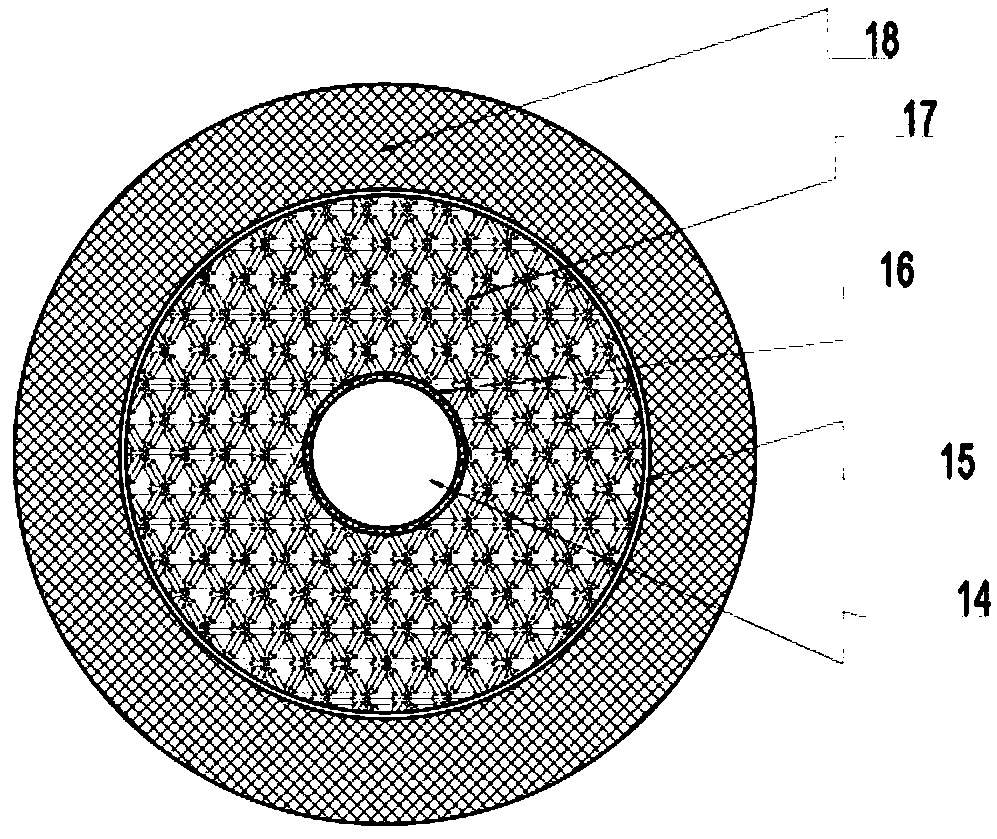

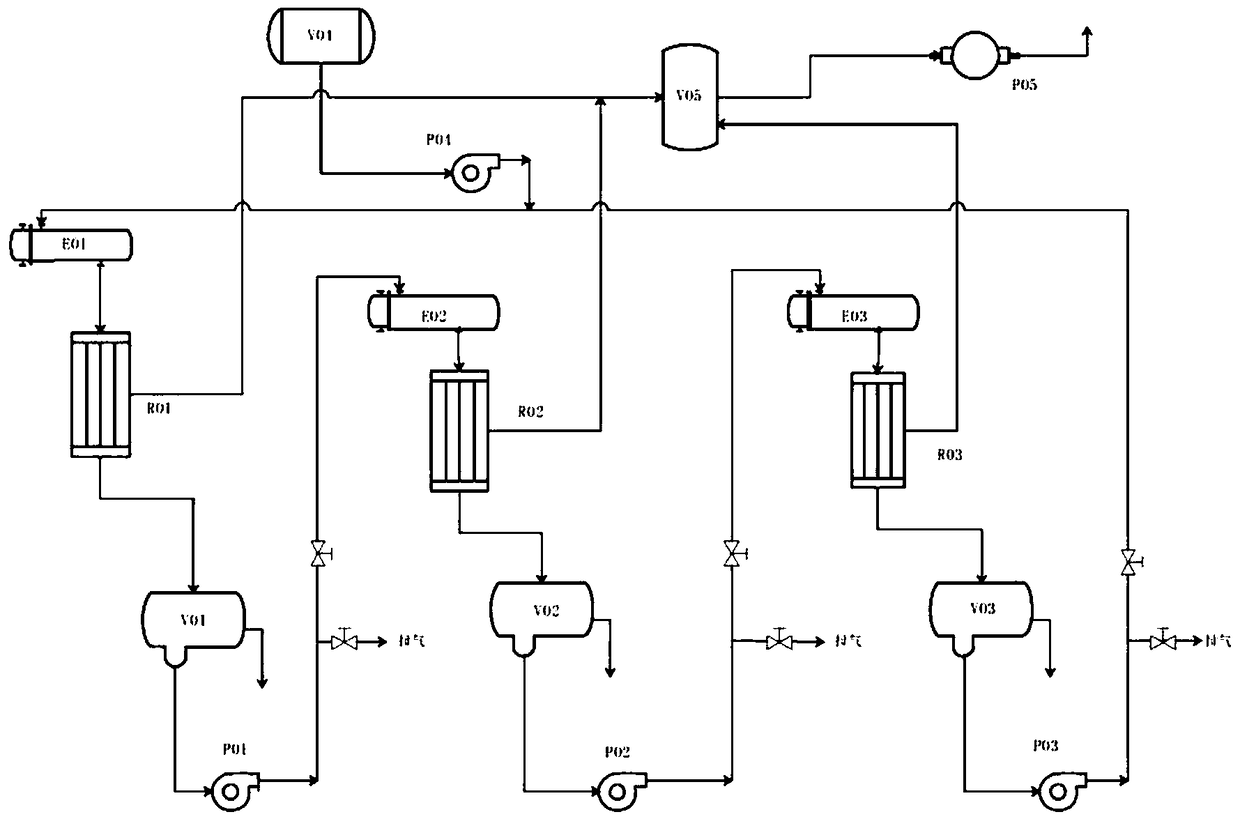

[0058] Put 400g of alanine, 651g of oxalic acid dihydrate, and 620g of ethanol into a 5L three-necked flask equipped with a stirring bar, a thermometer, and a condenser, and heat to dissolve at 80°C. After the heater is heated to 80-105°C, it is passed into the microchannel ceramic permeable membrane reactor for reaction. The cavity diameter of the membrane tube is 8mm, the flow rate of the feed liquid is 10ml / min, the pressure of the tube side is 0.3Mpa, and the pressure of the shell side is -0.1MPa. Dehydration while reacting, the reaction solution passing through the primary reactor enters the secondary and tertiary reactors for reaction, until the reaction system no longer has water detached and the reaction liquid water content is lower than 0.5%, the reaction is completed, and the total residence time is 20 hours; After finishing the reaction, the solvent in the reaction solution was removed by distillation under normal pressure, and diethyl oxalate was reclaimed by disti...

Embodiment 2

[0060] Put 400g of alanine, 651g of oxalic acid dihydrate, and 808g of n-propanol into a 5L three-necked flask equipped with a stirring bar, a thermometer, and a condenser, and heat to dissolve at 100°C. After the system is clarified, mix it evenly with 2346g of dipropyl oxalate , heated to 100-115°C by a heater, then passed into a microchannel ceramic permeable membrane reactor for reaction, the cavity diameter of the membrane tube is 8mm, the flow rate of the feed liquid is 10ml / min, the pressure of the tube side is 0.3Mpa, and the pressure of the shell side is -0.1 MPa, while dehydrating while reacting, the reaction liquid passing through the first-stage reactor enters the second and third-stage reactors to react until the reaction system no longer has water out and the water content of the reaction liquid is lower than 0.5%. The total residence time is 25%. hours; after finishing the reaction, the solvent in the reaction solution was removed by distillation under normal pre...

Embodiment 3

[0062] Put 400g of alanine, 651g of oxalic acid dihydrate, and 997g of n-butanol into a 5L three-necked flask equipped with a stirring bar, a thermometer, and a condenser, and heat to dissolve at 120°C. After the system is clarified, mix it evenly with 2723g of dibutyl oxalate , after being heated to 120-133°C by a heater, it is passed into a microchannel ceramic permeable membrane reactor for reaction. The cavity diameter of the membrane tube is 8mm, the flow rate of the feed liquid is 10ml / min, the pressure of the tube side is 0.3Mpa, and the pressure of the shell side is -0.1 MPa, while dehydrating while reacting, the reaction liquid passing through the first-stage reactor enters the second and third-stage reactors to react until the reaction system no longer has water out and the reaction liquid water content is lower than 0.5%. The total residence time is 28 hours; after finishing the reaction, the solvent in the reaction solution was removed by distillation at normal pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com