Gas ammonia recovery system and method for recovering discharged gas ammonia

A recovery system and emission technology, applied in the preparation/separation of ammonia, etc., can solve the problems of high energy consumption, energy consumption, and large project investment, and achieve high condensation efficiency, slow down energy loss, and achieve zero emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

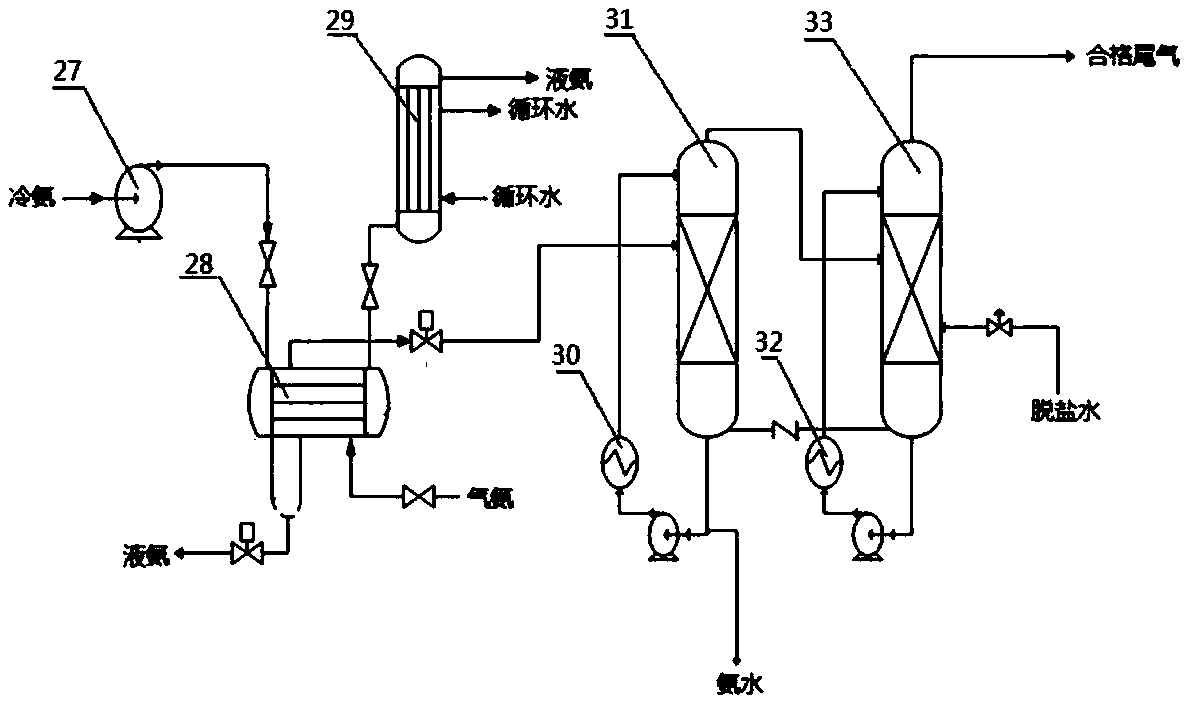

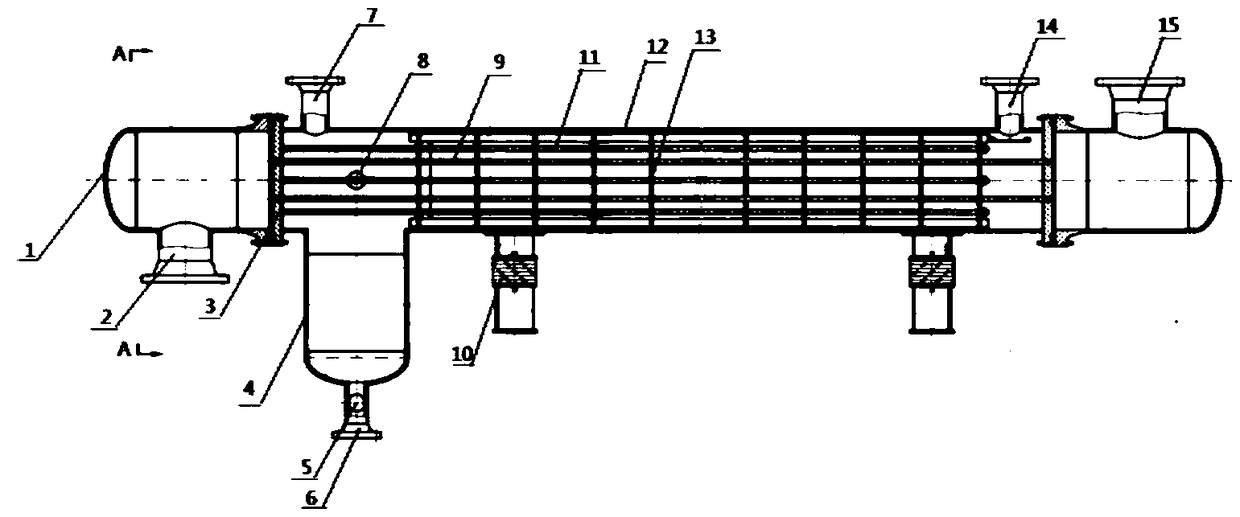

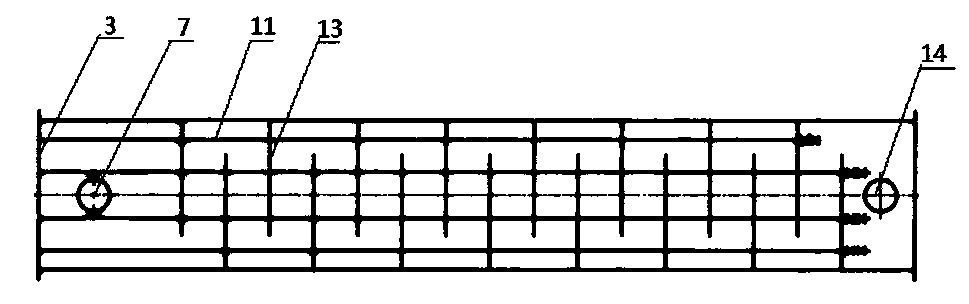

Method used

Image

Examples

Embodiment 1

[0066] Before the liquid ammonia tank car is filled with liquid ammonia, the tank is filled with saturated gas ammonia. The liquid ammonia filled into the tank car is supercooled liquid ammonia with a pressure of 2.0MPa and a temperature of 10°C. The tank car is generally controlled during filling. The pressure is less than or equal to 1.0Mpa, so some ammonia gas will be discharged when the liquid ammonia is loaded. When filling, the liquid ammonia first squeezes the gaseous ammonia to increase the pressure of the tank car to 1.0Mpa, and then starts to open the empty valve to vent. After the pressure reaches 1.0Mpa, filling 1 volume of liquid ammonia will discharge 1 volume of gaseous ammonia. The volume of a ton of liquid ammonia is 1.6m 3 , so filling 1 ton of liquid ammonia will produce 1.6m 3 ×8.4 ×(0.4 / 1.0)kg / m 3 = 5.376kg of gaseous ammonia, and because it is filled with supercooled liquid ammonia, the saturated gaseous ammonia in the tank car will continue to condense...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com