Multifunctional die cutting machine of corrugated papers for cartons

A corrugated paper and multi-functional technology, applied in the field of multi-functional die-cutting machines, can solve the problems of endangering the health of workers and not removing burrs, and achieve the effects of ensuring health, low cost and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

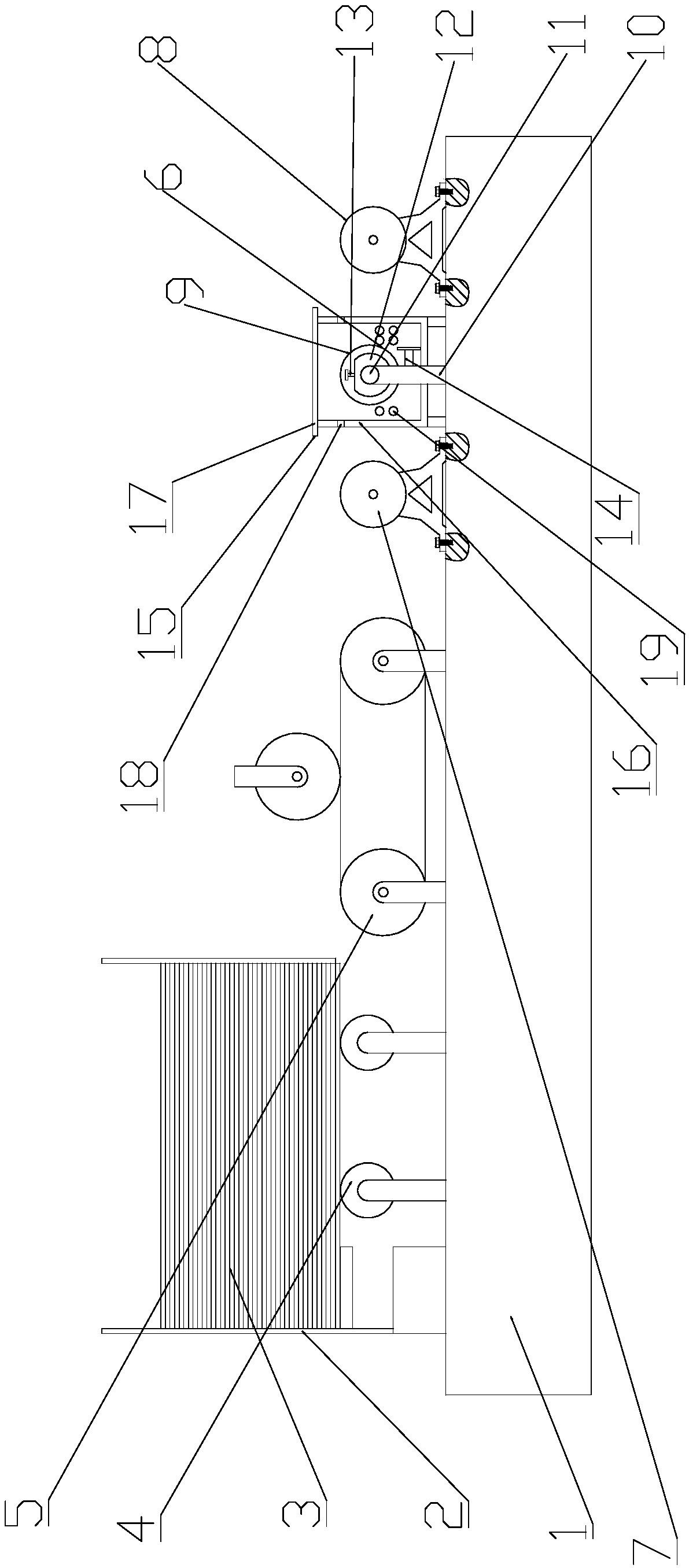

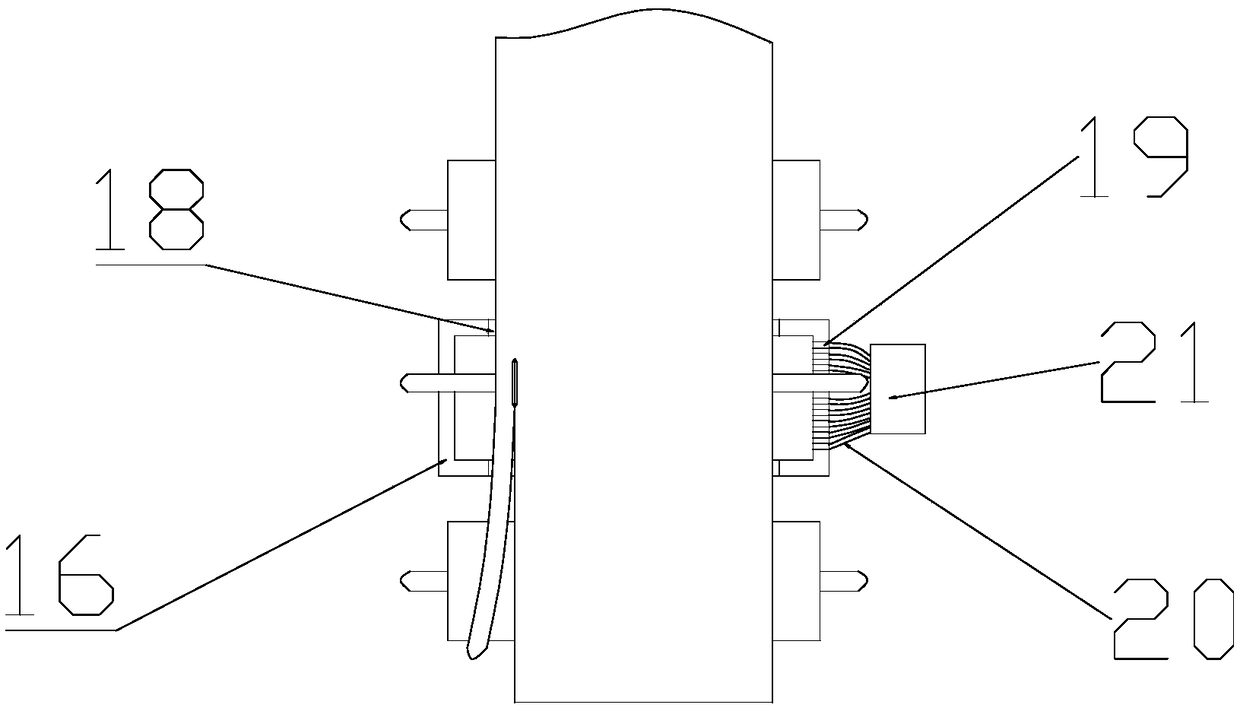

[0017] see figure 1 and figure 2 , a multifunctional die-cutting machine for corrugated paper for cartons, comprising a base 1, a raw material box 2, corrugated paper 3, a discharge roller 4, a flattening roller 5 and a cutting blade 6, and the upper left side of the base 1 is fixed with a raw material box 2. The corrugated paper 3 is placed in the raw material box 2, the bottom of the corrugated paper 3 is closely attached to the discharge roller 4, and the flattening roller 5 is arranged on the right side of the discharge roller 4. The cutting blade 6 is arranged on the right side of the flat roller 5; the left supporting roller 7 is arranged on the right side of the flattening roller 5, the right supporting roller 8 is arranged on the right side of the left supporting roller 7, and The support roller 7 and the right support roller 8 are fixed on the upper end surface of the base 1 by bolts. When the cutting blade 6 cuts the corrugated paper 3, the left support roller 7 an...

Embodiment 2

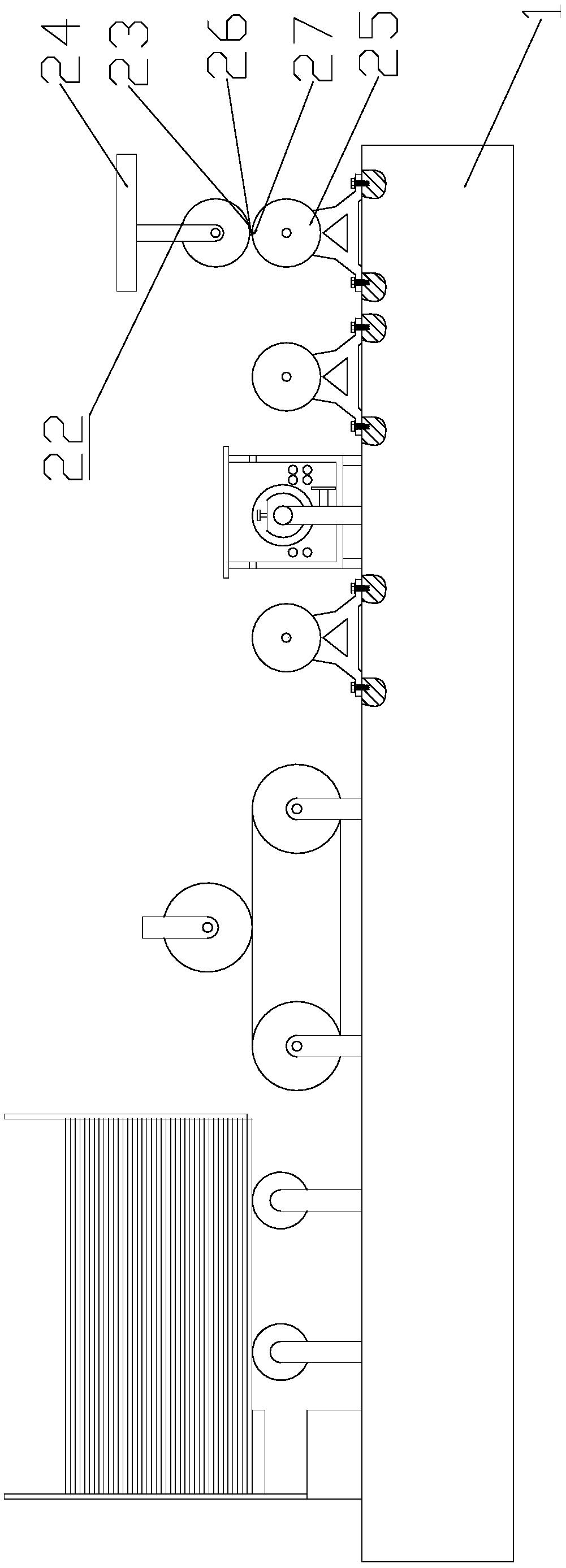

[0019] see image 3 and Figure 4 Compared with Embodiment 1, the present embodiment 2 differs only in that a length cutting mechanism 22 is arranged on the right side of the right support roller 8, and the length cutting mechanism 22 includes an upper cutting roller 23, a suspension beam 24, a lower cutting roller 25, Cutter 26 and knife groove 27, described upper cutting roller 23 bolts are fixed on the described suspension beam 24, described lower cutting roller 25 bolts are fixed on the described base 1, described upper cutting roller 23 is welded and fixed with cutting knife 26, the lower cutting roller 25 is processed with a knife groove 27; the upper cutting roller 23 and the lower cutting roller 25 rotate at the same speed and turn in the opposite direction. When passing between the cutting rollers 25, the corrugated paper 3 is cut every time the cutting knife 26 contacts the knife groove 27, and the cutting length is the outer circumference of the upper cutting rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com