Glove blow molding and film making forming linkage production method and glove blow molding and film making forming machine

A production method and molding machine technology, applied in household components, household appliances, other household appliances, etc., can solve the problems of defective gloves flowing into finished products, reducing production efficiency, and covering a wide area, so as to avoid defects that are not easy to be found, improve Product yield and the effect of reducing floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

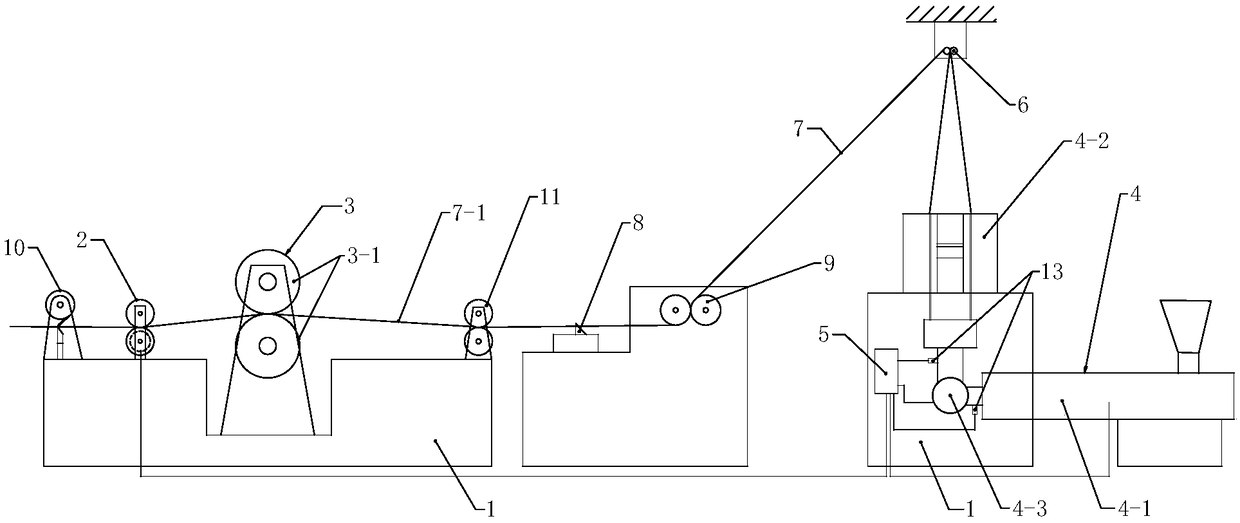

[0045] Such as figure 1 , figure 2 As shown, the glove film forming linkage production method includes the following specific steps:

[0046] a. Film making: use the film blowing mechanism 4 to make a continuous cylindrical film belt.

[0047] b. Finishing: introduce the tubular film strip into a pair of guide rollers 6 that abut against each other and rotate in opposite directions, and use these two guide rollers 6 to flatten the tubular film strip into a sheet-like double-layer film strip 7;

[0048] b1, cutting: the double-layer film belt 7 is cut into a plurality of double-layer sub-film belts 7-1 along the conveying direction;

[0049] c. Molding: use the traction mechanism to introduce the double-layer sub-film belt 7-1 into the glove forming mechanism 3 for hot pressing to form gloves. The glove forming mechanism 3 adopts a drum compression molding machine, and the commonly used drum compression molding machine is a PE glove machine.

[0050] The film blowing mechan...

Embodiment 2

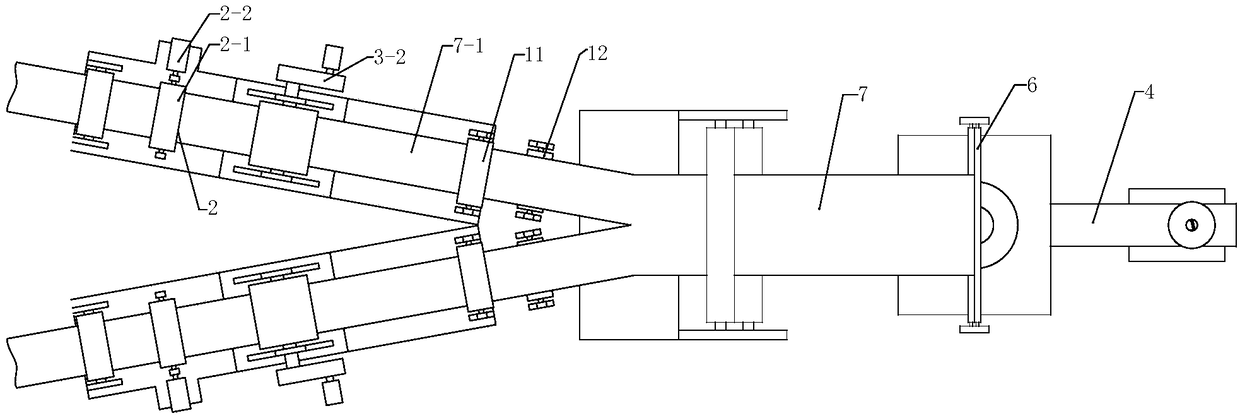

[0066] Such as image 3 with Figure 4 As shown, the glove film forming linkage production method includes the following specific steps:

[0067] a. Film making: use the film blowing mechanism 4 to make a continuous cylindrical film belt.

[0068] b. Finishing: introduce the tubular film strip into a pair of guide rollers 6 that abut against each other and rotate in opposite directions, and use these two guide rollers 6 to flatten the tubular film strip into a sheet-like double-layer film strip 7;

[0069] c. Molding: The traction mechanism 2 is used to introduce the double-layer film belt 7 into the glove forming mechanism 3 for hot pressing to form gloves. The glove forming mechanism 3 adopts a roller molding machine, and the commonly used roller molding machine is a PE glove machine.

[0070] The film blowing mechanism 4 described in step a includes a barrel 4-1 for plasticizing and extruding the resin, a die head 4-2 communicated with the barrel 4-1, and a melter correspon...

Embodiment 3

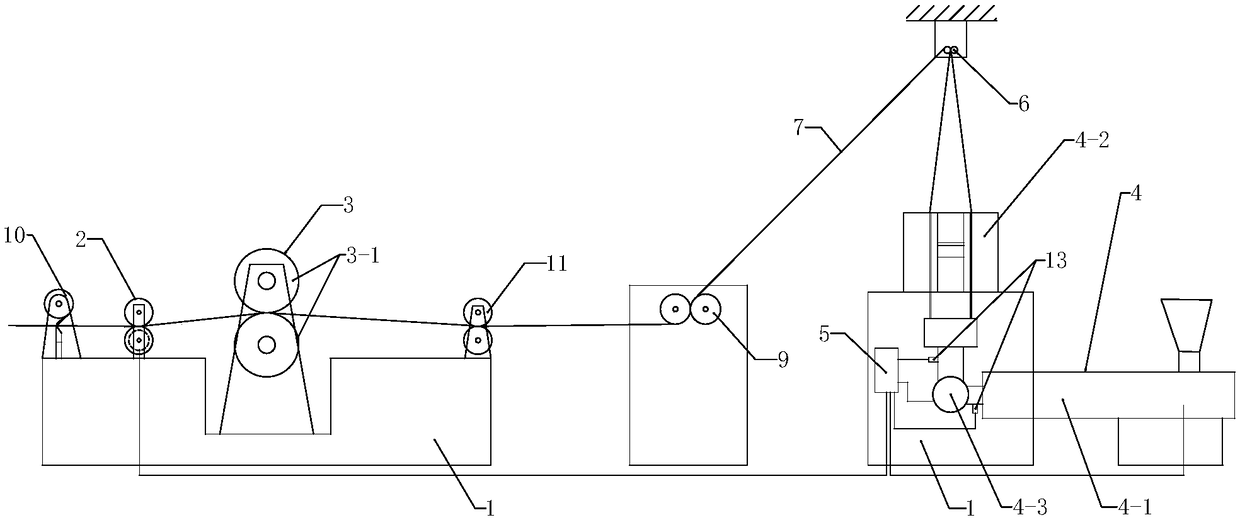

[0082] Such as Figure 5 , Image 6 As shown, the glove film forming linkage production method includes the following specific steps:

[0083] a, film making: Utilize the film blowing mechanism 4 to make a continuous cylindrical film strip; wherein, the film blowing mechanism 4 includes a machine barrel 4-1, a die head 4-2 connected with the machine barrel 4-1, and the machine barrel In 4-1, the plasticized resin is extruded into the die head 4-2 through the screw. The die head 4-2 includes a ring-shaped outer mold and a ring-shaped inner mold coaxially arranged. A ring-shaped cavity is formed between the inner and outer molds. There is a fan, one end of the annular cavity communicates with the machine barrel, and the other end is the extrusion end. The barrel plasticizes the resin and squeezes it into the cavity and extrudes from the extrusion end of the cavity, and forms a cylinder under the cooling of the fan. film strips.

[0084] b. Finishing: introduce the tubular fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com