Iron porphyrin-flaky bismuth tungstate two-dimensional composite material and preparation method thereof

A composite material, iron porphyrin technology, applied in chemical instruments and methods, water treatment of special compounds, organic compound/hydride/coordination complex catalysts, etc., can solve the problems of increasing costs and expenses, achieve enhanced absorption, promote Effects of shifting, enhancing availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

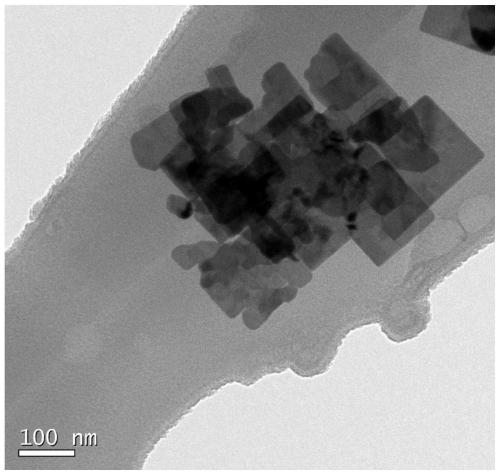

[0031] An iron porphyrin-flaky bismuth tungstate two-dimensional composite material comprises iron porphyrin and flake bismuth tungstate, wherein the iron porphyrin is fixed on the surface of the flake bismuth tungstate.

[0032] In this embodiment, the mass ratio of iron porphyrin to flaky bismuth tungstate in the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 0.5%.

[0033] In this embodiment, the size (length×width) of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 150 nm×250 nm, and the thickness is 5.9 nm.

[0034] A preparation method of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material of the above-mentioned present embodiment, comprising the following steps:

[0035] (1) Add iron porphyrin into methanol so that the concentration of the iron porphyrin dispersion is 1 mg / mL, stir for 10 min at a rotational speed of 800 r / min, ultrasonicate for 15 min, and mix evenly to obtain an i...

Embodiment 2

[0042] An iron porphyrin-flaky bismuth tungstate two-dimensional composite material comprises iron porphyrin and flake bismuth tungstate, wherein the iron porphyrin is fixed on the surface of the flake bismuth tungstate.

[0043] In this embodiment, the mass ratio of iron porphyrin to flaky bismuth tungstate in the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 1.0%.

[0044] In this embodiment, the size (length×width) of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 150 nm×250 nm, and the thickness is 5.9 nm.

[0045] A preparation method of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material of the above-mentioned present embodiment, comprising the following steps:

[0046] (1) Add iron porphyrin into methanol so that the concentration of the iron porphyrin dispersion is 1 mg / mL, stir for 10 min at a rotational speed of 800 r / min, ultrasonicate for 15 min, and mix evenly to obtain an i...

Embodiment 3

[0057] An iron porphyrin-flaky bismuth tungstate two-dimensional composite material comprises iron porphyrin and flake bismuth tungstate, wherein the iron porphyrin is fixed on the surface of the flake bismuth tungstate.

[0058] In this embodiment, the mass ratio of iron porphyrin to flaky bismuth tungstate in the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 3.0%.

[0059] In this embodiment, the size (length×width) of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material is 150 nm×250 nm, and the thickness is 5.9 nm.

[0060] A preparation method of the iron porphyrin-flaky bismuth tungstate two-dimensional composite material of the above-mentioned present embodiment, comprising the following steps:

[0061](1) Add iron porphyrin into methanol so that the concentration of the iron porphyrin dispersion is 1 mg / mL, stir for 10 min at a rotational speed of 800 r / min, ultrasonicate for 15 min, and mix evenly to obtain an ir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com