High-efficiency flue gas downstream dust removal, desulfurization and whitening method and device

A flue gas, high-efficiency technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve the problems of low system operation stability, reduced purification efficiency, serious smoke plumes, etc., to achieve high removal efficiency, eliminate smoke feather effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

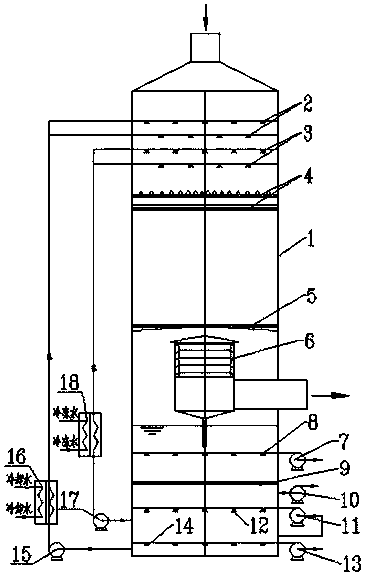

[0047] Such as figure 1 As shown, the present invention mainly consists of a spray washing tower (1), a high-level spray layer (2), a low-level spray layer (3), a downstream Venturi gas-liquid distributor (4), a rotary Flow gas-liquid separator (5), downstream tower mist eliminator (6), oxidation fan (7), oxidation air distribution device (8), uniform flow orifice plate (9), slurry discharge pump (10), slurry disturbance Pump (11), slurry turbulence distributor (12), slurry dosing pump (13), slurry dosing distributor (14), cooling slurry circulating pump (15), cooling water heat exchanger (16), freezing slurry Circulation pump (17), chilled water heat exchanger (18).

[0048] Such as figure 1 As shown, the flue gas enters from the upper inlet of the spray scrubber, mixes with the absorption liquid droplets sprayed by the spray layer, goes down the tower, and is fully transferred by the function of the downstream Venturi gas-liquid distributor. , a large amount of water in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com