Agricultural cotton bowl extrusion-forming machine

An extrusion forming and cotton technology, which is applied in the field of agricultural cotton pier extrusion forming machines, can solve the problems of low production efficiency, poor control of cotton pot density, large labor force, etc. The effect of compaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

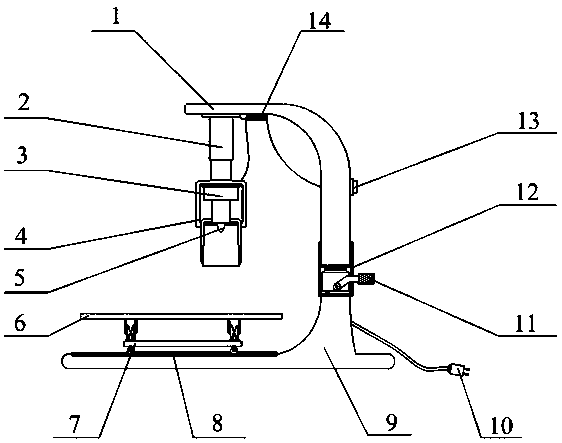

[0022] as attached figure 1 to attach Figure 4 shown

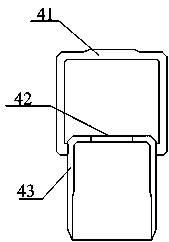

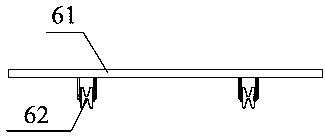

[0023] The present invention provides an agricultural cotton pier extrusion molding machine, comprising a bracket arm 1, a first electric push rod 2, a second electric push rod 3, a mold barrel 4, a push plate 5, a first slide plate 6, a second slide plate 7, The first slide rail 8, the base 9, the power cord 10, the hydraulic top 11, the connecting shell 12, the switch 13 and the power supply controller 14, the first electric push rod 2 is fixed under the top of the support arm 1 by threads and connected with the wires The switch 13 is connected with the power supply controller 14; the second electric push rod 3 is fixed in the first fixed shell 41 of the mold barrel 4 by threads and is connected with the switch 13 and the power supply controller 14 by a wire; the mold barrel 4 is connected by The thread is fixed on the top of the first electric push rod 2; the push plate 5 is arranged inside the first fixed shell 41 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com