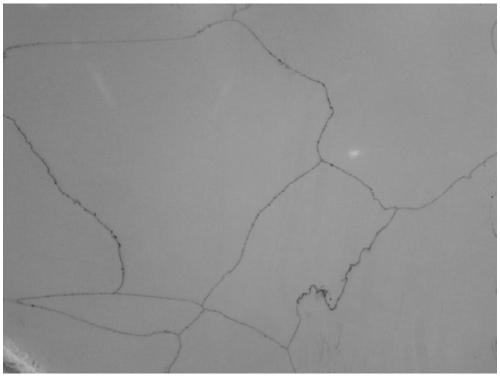

Natural-cross-texture engineered stone and preparation method thereof

A kind of textured granite, natural technology, applied in the field of natural textured granite and its preparation, can solve the problems of unnaturalness, difficulty in having natural marble texture, and inability to realize reasonable mineral resources, so as to meet the market demand and enrich the variety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing natural reticulated stone includes the following steps:

[0026] (1) Weigh the raw materials according to the mass percentage, and the total mass is 100%. Weigh 46.524% of white dolomite 90 mesh sand, 46.618% of modified calcium carbonate powder, 6.32% of unsaturated polyester resin, 0.45% of mixed pigment, curing Agent 0.08%, accelerator 0.008%; the mixed pigment is composed of Bayerlo’s iron-based pigment and DuPont’s titanium dioxide (R706);

[0027] (2) Add the accelerator to the unsaturated polyester resin and mix for more than 5 minutes, and then set aside; transport the weighed dolomite 90 mesh sand and modified calcium carbonate powder to the mixer through the conveyor belt, and transfer the weighed mixed pigment Put these three materials into the mixer, mix and stir for 5 minutes, then add the mixture of unsaturated polyester resin and accelerator and curing agent into the mixer at the same time and mix at high speed for 18 minutes, the freque...

Embodiment 2

[0031] (1) Weigh the raw materials according to the mass percentage, and the total mass is 100%. Weigh 45.277% of white dolomite 90 mesh sand, 47.725% of modified calcium carbonate powder, 6.46% of unsaturated polyester resin, 0.45% of mixed pigment, and solidification Agent 0.08%, accelerator 0.008%; the mixed pigment is composed of Bayerlo’s iron-based pigment and DuPont’s titanium dioxide (R706);

[0032] (2) Add the accelerator to the unsaturated polyester resin and mix for more than 5 minutes, and then set aside; transport the weighed dolomite 90 mesh sand and modified calcium carbonate powder to the mixer through the conveyor belt, and transfer the weighed mixed pigment Put these three materials into a mixer, mix and stir for 5 minutes, then add the mixture of unsaturated polyester resin and accelerator and curing agent into the mixer at the same time, mix and stir at high speed for 18 minutes, the frequency of high-speed stirring is 65Hz, the process of stirring In, observ...

Embodiment 3

[0035] (1) Weigh the raw materials according to the mass percentage, and the total mass is 100%. Weigh 44.817% of white dolomite 90 mesh sand, 48.15% of modified calcium carbonate powder, 6.52% of unsaturated polyester resin, 0.45% of mixed pigment, and solidification Agent 0.08%, accelerator 0.008%; the mixed pigment is composed of Bayerlo’s iron-based pigment and DuPont’s titanium dioxide (R706);

[0036] (2) Add the accelerator to the unsaturated polyester resin and mix for more than 5 minutes, and then set aside; transfer the weighed dolomite 90 mesh sand and modified calcium carbonate powder to the mixer through the conveyor belt, and manually weigh it. Pour the mixed pigments into the mixer, mix and stir these three materials for 5 minutes, then add the mixture of unsaturated polyester resin and accelerator and curing agent to the mixer at the same time and mix at high speed for 18 minutes, the frequency of high-speed stirring is 65Hz, stirring During the process, observe w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com