A method for burning desulfurization of petroleum coke and reducing the content of Glauber's salt in the glass industry

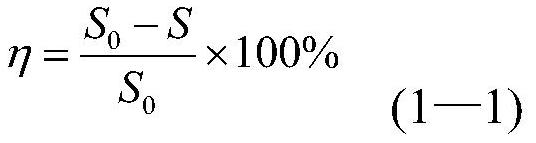

Glauber's salt content, glass industry technology, applied in the petroleum industry, glass furnace equipment, glass manufacturing equipment and other directions, can solve the problems of serious combustion pollution, high sulfur content of petroleum coke, no reports, etc., to achieve good economic benefits and social Benefit, low desulfurization cost and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for burning desulfurization of petroleum coke and reducing the content of Glauber's salt in the glass industry, comprising the following steps:

[0041] (1) Blending: In the petroleum coke powder used as the fuel of the glass melting furnace, a desulfurization agent-activated calcium oxide is added. The chemical molar ratio of activated calcium oxide and sulfur in the petroleum coke powder is 1:1, that is, the Add 5.67kg of active calcium oxide to the petroleum coke powder and mix it evenly;

[0042] (2) Grinding: the mixture obtained in step (1) is ground and passed through a 200-mesh sieve, and after sieving, petroleum coke powder containing a desulfurizing agent is obtained;

[0043] (3) Desulfurization: Mix petroleum coke powder containing desulfurizing agent with 0.5MPa compressed air to form a fluidized solid-gas two-phase fluid, which is transported by air from 1 # ,2 # The fuel nozzle below the small furnace is sprayed into the front section of the me...

Embodiment 2

[0051] A method for burning desulfurization of petroleum coke and reducing the content of Glauber's salt in the glass industry, comprising the following steps:

[0052] (1) Blending: In the petroleum coke powder used as the fuel of the glass melting furnace, a desulfurizer-activated calcium oxide is mixed, and the chemical molar ratio of activated calcium oxide to sulfur in the petroleum coke powder is 2:1, that is, in 100kg of the above-mentioned Add 11.34kg of active calcium oxide into the petroleum coke powder and mix it evenly;

[0053] (2) Grinding: the mixture obtained in step (1) is ground and passed through a 200-mesh sieve, and after sieving, petroleum coke powder containing a desulfurizing agent is obtained;

[0054] (3) Desulfurization: Mix petroleum coke powder containing desulfurizing agent with 0.5MPa compressed air to form a fluidized solid-gas two-phase fluid, which is transported by air from 1 # ,2 # The fuel nozzle below the small furnace is sprayed into th...

Embodiment 3

[0062] A method for burning desulfurization of petroleum coke and reducing the content of Glauber's salt in the glass industry, comprising the following steps:

[0063] (1) Blending: In the petroleum coke powder used as a fuel for a glass melting furnace, a desulfurizer-activated calcium oxide is added. Add 17.01kg of activated calcium oxide to the petroleum coke powder and mix it evenly;

[0064] (2) Grinding: the mixture obtained in step (1) is ground and passed through a 200-mesh sieve, and after sieving, petroleum coke powder containing a desulfurizing agent is obtained;

[0065] (3) Desulfurization: Mix petroleum coke powder containing desulfurizing agent with 0.6MPa compressed air to form a fluidized solid-gas two-phase fluid, which is transported by air from 1 # ,2 # The fuel nozzle below the small furnace is sprayed into the front section of the melting part of the float glass melting furnace, namely 1 # ,2 # Combustion is carried out in a small furnace to realize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com