Variable pitch device and installation method thereof

A pitch-variable and pitch-variable mechanism technology, applied in the field of aircraft, can solve problems such as easy vibration, wear control accuracy of the pitch-variable mechanism, and reduce control accuracy, and achieve higher reliability and service life, high reliability and service life, and structural form. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

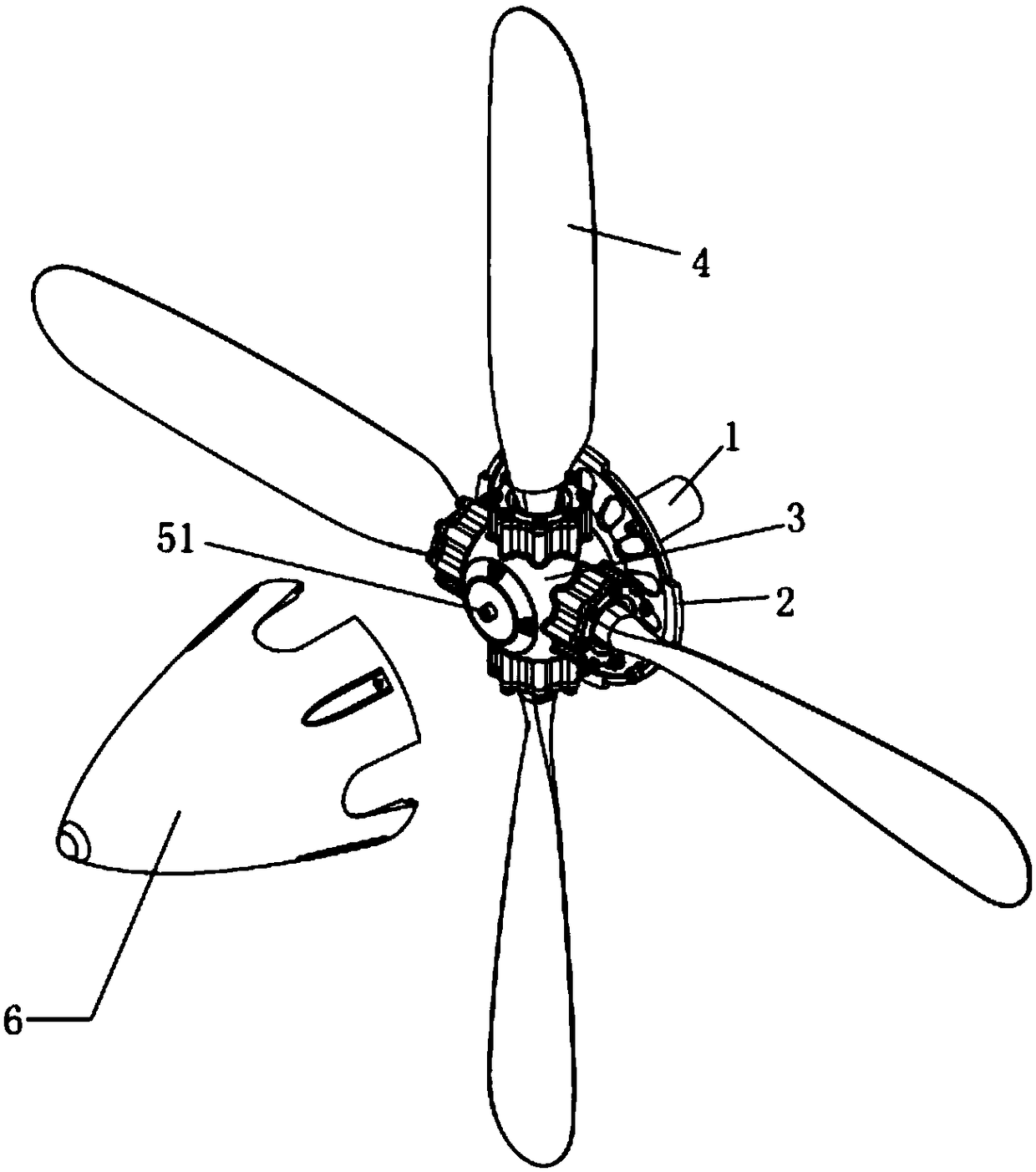

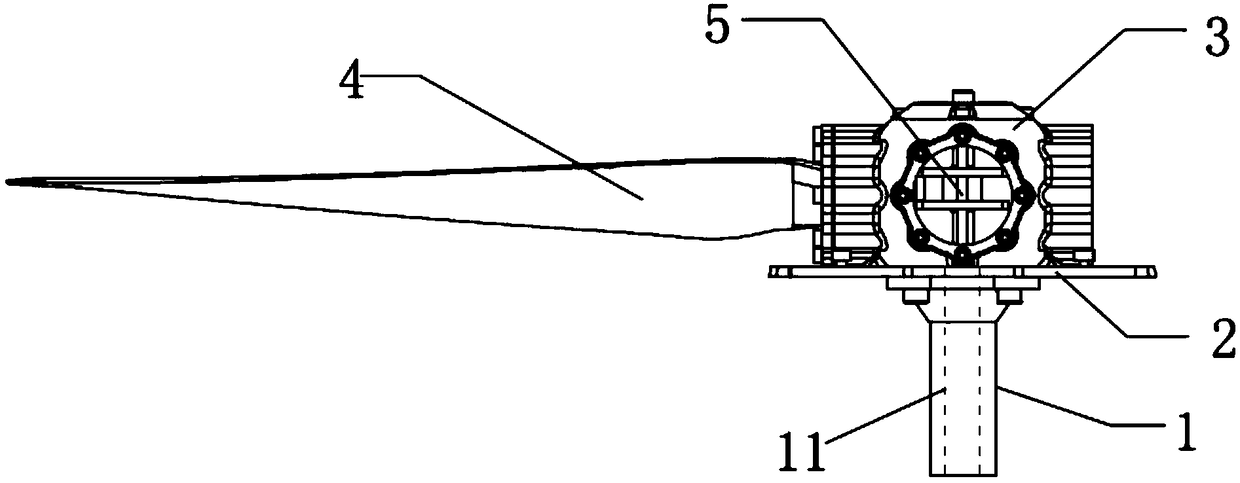

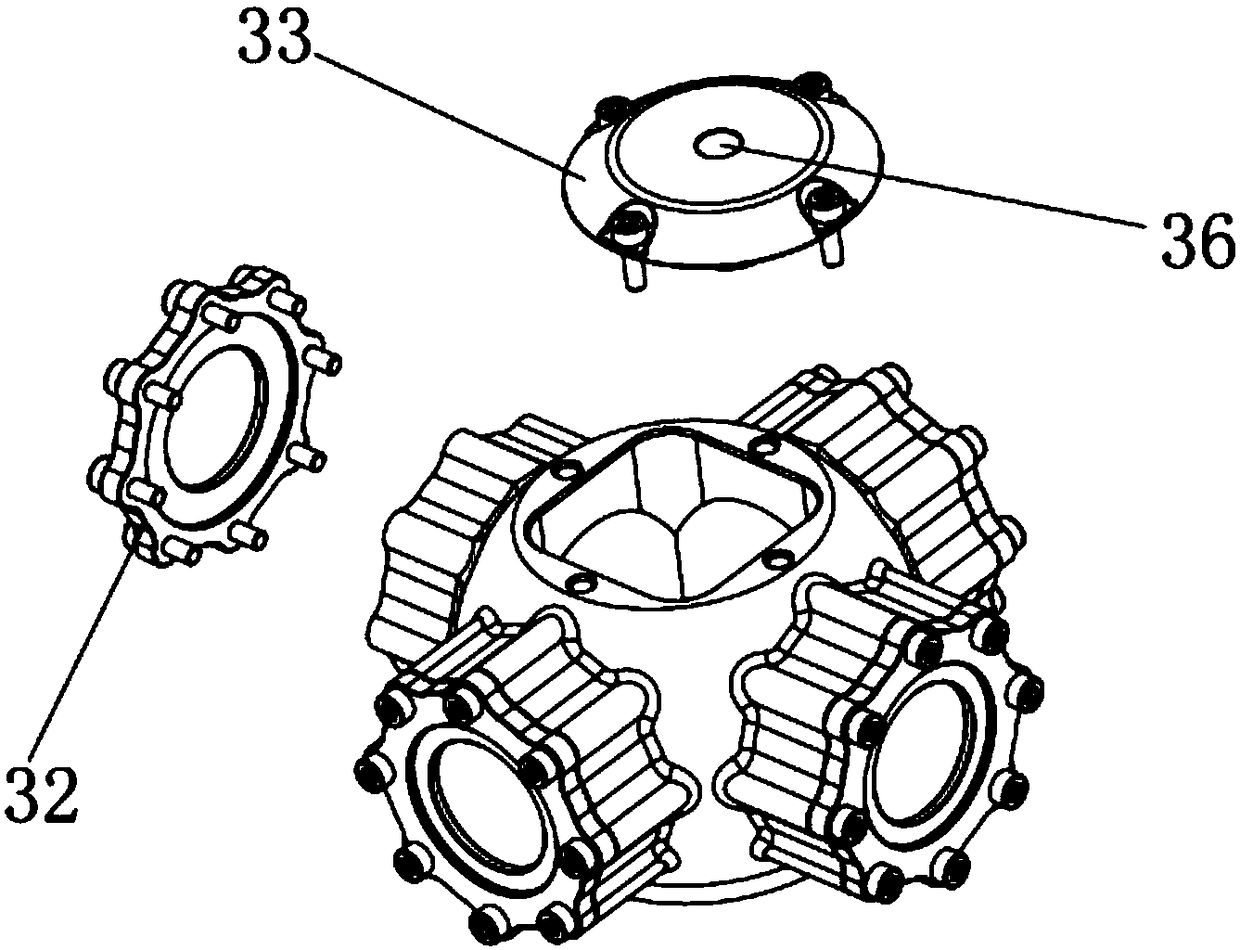

[0033] Such as Figure 1 to Figure 6 Shown, a kind of pitch control device that is applied in the aircraft shown in this embodiment includes propeller hub 3, four propeller blades 4 that are movable around the propeller hub 3 at equidistant intervals and movable on the propeller hub 3. The crank arm mechanism in the propeller hub 3 and the variable pitch mechanism 5, the pitch variable mechanism 5 can move back and forth along the axial direction of the propeller hub 3, and rotate together with the propeller hub 3 during work; The mechanism 5 is connected, and the crank arm mechanism rotates with the movement of the pitch variable mechanism 5. The other end of the crank arm mechanism protrudes from the propeller hub 3 and is connected with the propeller blade, and the arc displacement axis of the crank arm mechanism is aligned with the propeller blade. The rotation axis of the propeller pitch is the same, and the linear displacement of the pitch variable mechanism along the ax...

Embodiment 2

[0043] The present invention also provides a method for installing the pitch control device described in Embodiment 1, comprising the following steps:

[0044] S1. First connect the movable ejector rod in the pitch variable mechanism with the connecting rod in the propeller rotating shaft, and then insert the anti-twist strut on the upper splint and the lower splint;

[0045] S2. Set the propeller hub outside the pitch changing mechanism and fix it on the fixed base plate, and then install the top cover;

[0046] S3. Assemble the tapered thread jacket and the cylindrical crank arm boss through pins, and sequentially set washers and clamps on the outer circumference of the tapered thread jacket (the clamps include two semicircular clamps and a circular clamp), forming Crank arm mechanism;

[0047] S4. Install the crank arm mechanism into the propeller hub through the through hole of the installation part and fix it with the blade cover, and the boss inside the cylindrical cran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com