Heating insole based on printed electronics

A technology for printing electronics and insoles, applied in the field of insoles, can solve the problems of reducing the service life of electric heating insoles, inconvenient cleaning, waste of resources, etc., and achieve the effects of mass production, resource saving, and light size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

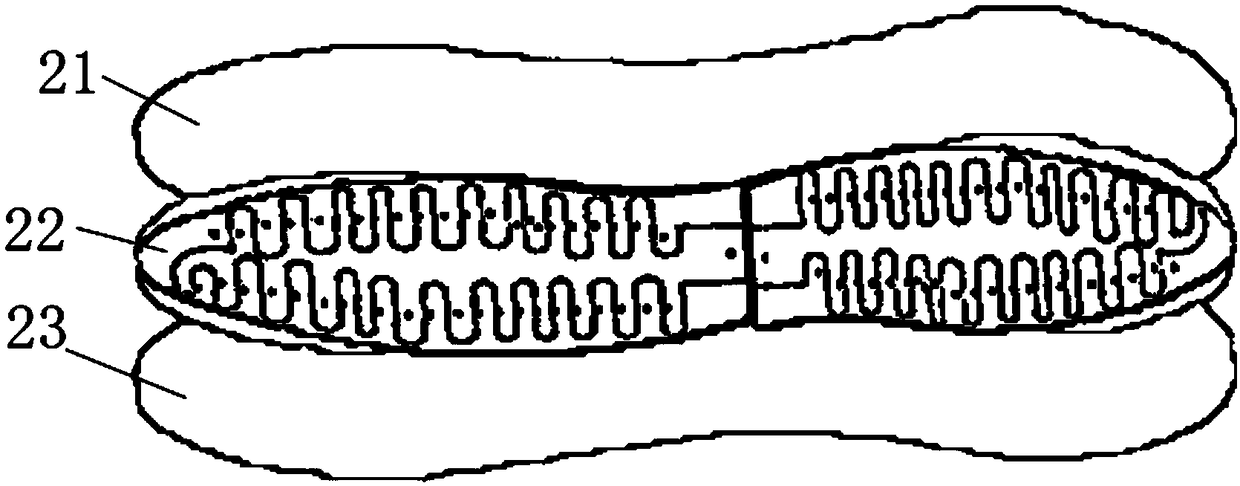

[0028] A heat-generating insole based on printed electronics, such as figure 1 As shown, it includes insole outer layer 1, heating layer 2, power supply layer 3, insole bottom layer 4 stacked in sequence from top to bottom, and a control switch 5 arranged between heating layer 2 and power supply layer 3. The outer layer 1 of the insole is located at the top and directly contacts the sole of the user's foot, and the bottom layer of the insole 4 is located at the bottom and directly contacts the inner bottom surface of the shoe. The outer layer of the insole 1 and the bottom layer of the insole 4 are used to protect the heating layer 2 and the power supply layer 4, and at the same time make the user more comfortable when using it. Compared with the power supply layer 3, the heating layer 2 is closer to the outer layer 1 of the insole, so that the heat emitted by the heating insole is more easily transmitted to the sole of the user. The outer layer 1 of the insole, the heating l...

Embodiment 2

[0036] Compared with Embodiment 1, the heating insole based on printed electronics in this embodiment has the following differences: such as image 3 As shown, the power supply circuit 32 includes three power sources 321 and three adjustment switches 322 , and the power sources 321 and the adjustment switches 322 correspond one to one. The negative poles of all the power supplies 321 are connected to each other, and the positive poles of the power supplies 321 are respectively connected to one end of the corresponding adjustment switch 322, and the other ends of the adjustment switches 322 are connected to each other, so that each power supply 321 forms a parallel group with the corresponding adjustment switch 322, and all parallel connections The groups are connected in parallel to form a power supply circuit 32 , and the two ends of any parallel group are taken out as terminals of the power supply circuit 32 . The three regulating switches 322 are all single-stage pressure s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com