A lead support frame for mechanical vibration de-icing of an eight-split lead

A mechanical vibration and eight-split technology, which is applied in overhead installation, cable installation, electrical components, etc., can solve the problems of low deicing efficiency and poor clamping effect, and achieve good deicing effect, enhanced stability effect, and good stability effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

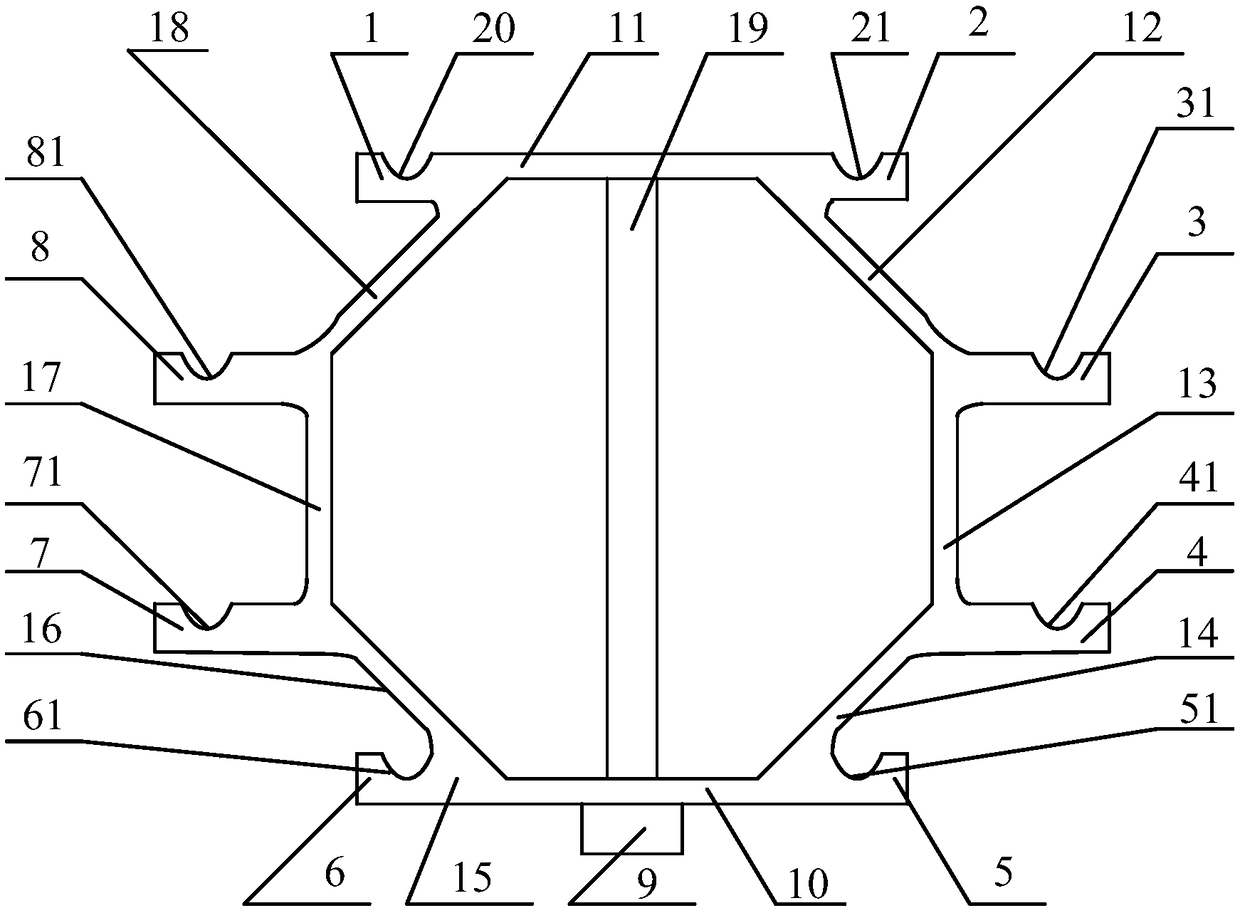

[0017] See figure 1 , A wire support frame for mechanical vibration deicing of eight-split wires, comprising an ice-breaking head 9 and a clamping portion 10 connected to each other. The clamping portion is provided with eight connection portions, namely the first connection portion 1 , No. 2 wiring section 2, No. 3 wiring section 3, No. 4 wiring section 4, No. 5 wiring section 5, No. 6 wiring section 6, No. 7 wiring section 7 and No. 8 wiring section 8.

[0018] The clamping portion 10 is an octagonal structure, which in turn includes an upper top 11, an upper right 12, a middle right 13, a lower right 14, a lower bottom 15, a lower left 16, a middle left 17 and an upper left 18 connected to each other. The central axes of the parallel upper top 11 and the lower bottom 15 coincide with each other. The lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com