An intelligent control method of maintenance work order management

A technology for maintenance workers and maintenance personnel, which is applied in the field of intelligent control of maintenance work order management, which can solve problems that affect the work efficiency of maintenance personnel, cannot be processed in time, and omission of fault repair information, etc., to ensure maintenance efficiency and maintenance effect, fast And accurate maintenance, improve the effect of maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

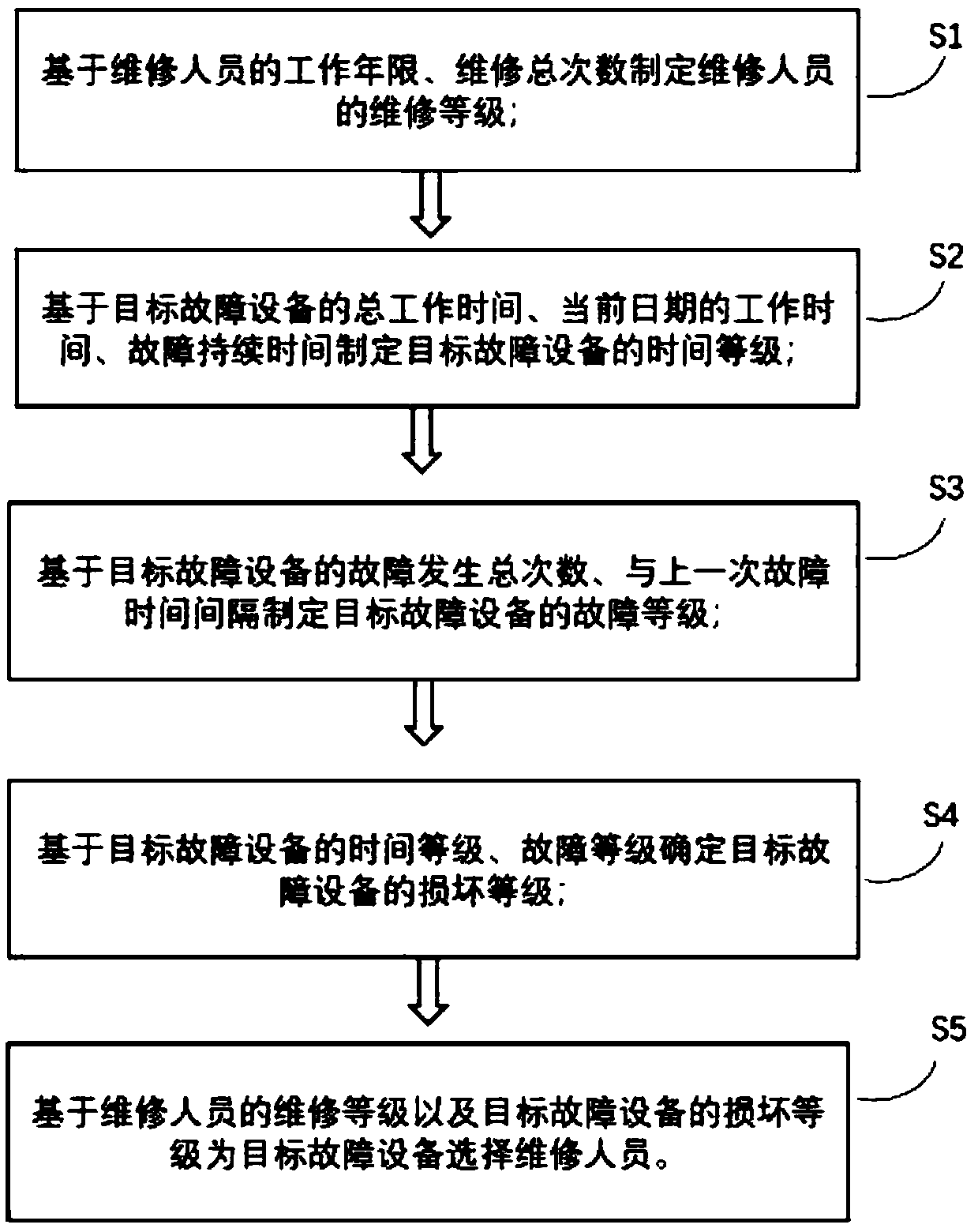

[0049] Such as figure 1 As shown, figure 1 It is an intelligent control method for maintenance work order management proposed by the present invention.

[0050] Reference figure 1 , The intelligent control method for maintenance work order management proposed by the present invention includes the following steps:

[0051] S1. Establish the maintenance level of maintenance personnel based on the working years of maintenance personnel and the total number of maintenance;

[0052] In this embodiment, the preset age Y is stored in step S1 0 , Preset times N 0 ;

[0053] Step S1 specifically includes:

[0054] Obtain the working years of the maintenance personnel and the total number of maintenance, and record them as Y, N;

[0055] Separate the working years Y of the maintenance personnel and the preset years Y 0 , Total maintenance times N and preset times N 0 Compare:

[0056] When Y 0 , N 0 Establish maintenance personnel as the first maintenance level;

[0057] When Y 0 , N≥N 0 At the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com