Stretching clamping type engine oil pan oil drainage blocking system and method for applying same

An engine oil and oil pan technology, applied in the directions of oil pan, engine components, machine/engine, etc., can solve the problem of torque control, etc., and achieve the effects of easy operation, firm connection and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

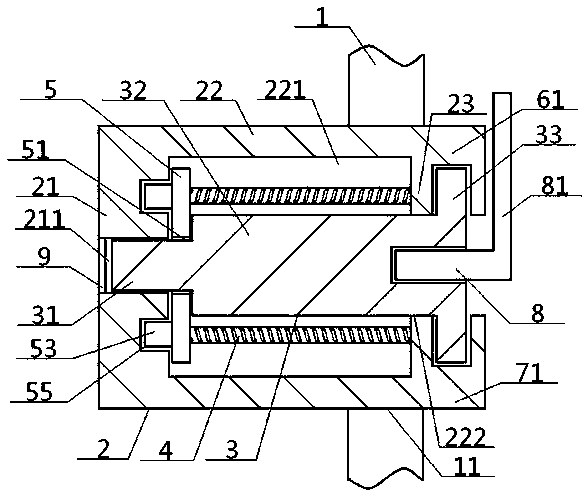

[0057] see Figure 1 to Figure 5 , a stretching clamping type engine oil pan oil drain plugging system, comprising a fixed seat 2 inside the shell and a plugging member 3 outside the shell, the outer wall of the fixed seat 2 inside the shell and the oil drain hole 11 in the oil pan 1 The inner walls are connected, and an insertion cavity 24 is opened inside the fixed seat 2 inside the shell, and the inserted cavity 24 is inserted into and matched with the inserting column 34 in the plugging member 3 outside the shell; the fixed seat 2 in the shell includes fixed front columns connected in sequence Body 21, fixed middle cylinder 22, and fixed rear cylinder 23. The fixed front cylinder 21 and fixed middle cylinder 22 are all located in the oil pan 1, and the fixed rear cylinder 23 is located outside the oil pan 1. There is a front column cavity 211 inside the column body 21, the outer wall of the fixed center column body 22 is connected with the inner wall of the oil discharge h...

Embodiment 2

[0062] Basic content is the same as embodiment 1, the difference is:

[0063] The outer surface of the piston sleeve 5 is provided with an upper guide column 52 and a lower guide column 53. The upper guide column 52 and the lower guide column 53 are vertically symmetrical with the central axis of the piston sleeve 5 as the line of symmetry. The upper guide column 52, The lower guide post 53 is respectively inserted into the upper guide hole 54 and the lower guide hole 55 provided in the fixed front column body 21 , and the upper guide post 52 and the lower guide post 53 are both shorter than the front insert post 31 .

Embodiment 3

[0065] Basic content is the same as embodiment 1, the difference is:

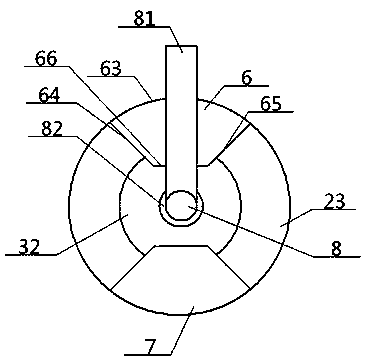

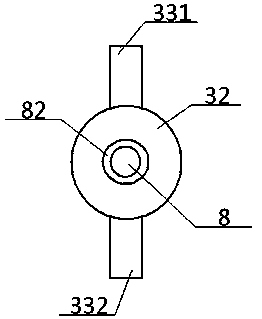

[0066] Described rear clamping body 33 comprises upper clamping block 331, lower clamping block 332, and described upper clamping block 331, lower clamping block 332 are respectively connected with the top, the bottom of middle inserting post 32 rear ends, upper clamping block 331, lower clamping block The outer surfaces of 332 are all flush with the outer surfaces of the middle post 32 rear ends, and the upper block 331 and the lower block 332 are point-symmetrical with the center of the center of the middle post 32 rear ends as the symmetrical point. The upper block 331 and the lower block The width of 332 is less than the radius of the rear end of the middle post 32; the central part of the fixed back post 23 is provided with a middle back hole 222, and the top of the outer side of the fixed back post 23 is vertically connected with one end of the upper middle connecting block 61, The other end of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com