Assisting upper cover lock with cam structure

A cover lock and cam technology, applied in building locks, building structures, instruments, etc., can solve the problems of easy disassembly and assembly of the upper cover, poor operating experience, and inconvenient operation, so as to improve the operating experience, low cost, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to better understand the present invention, the specific implementation manners of the present invention will be explained in detail below in conjunction with the accompanying drawings.

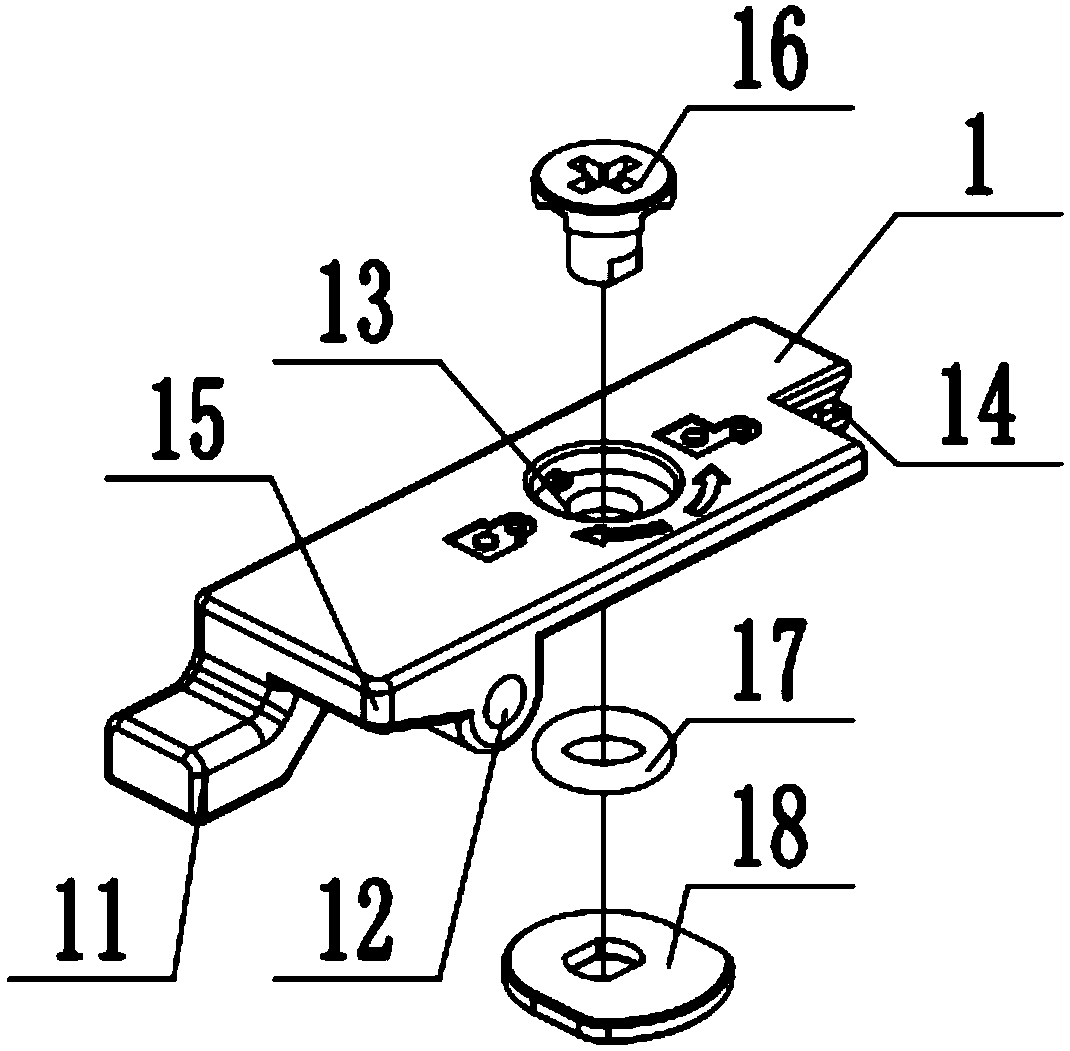

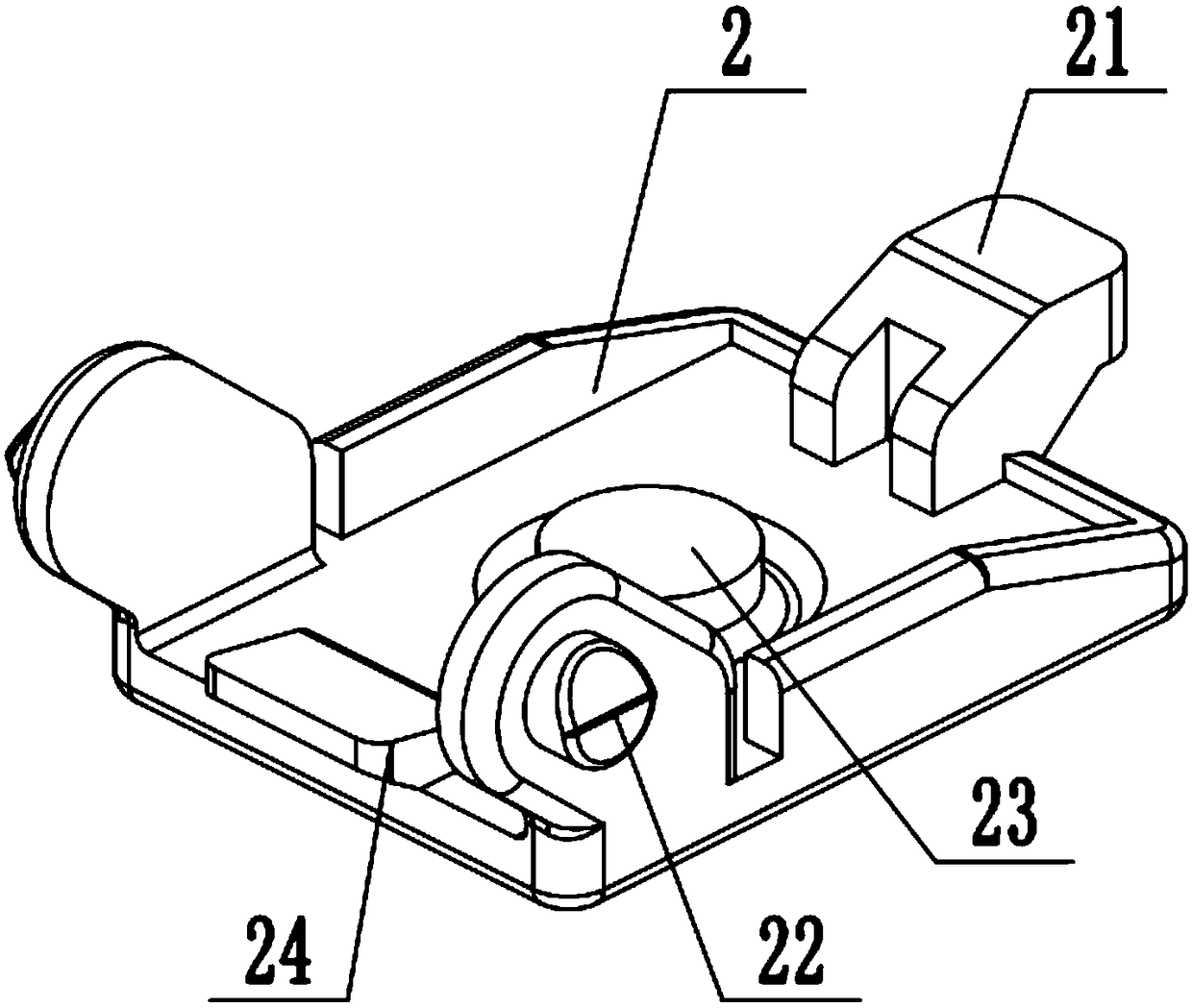

[0033] A power-assisted upper cover lock with a cam structure, comprising a chassis 5, a chassis upper cover 6, and a lid lock connecting the chassis 5 and the chassis upper cover 6, the chassis upper cover 6 cooperates with the chassis 5 through the upper cover slot 51, and the The upper cover lock includes a handle 1, a button 2, a housing 3, and a cam bracket 4. The housing 3 is installed on the upper cover 6 of the chassis, and the cam bracket 4 is installed on the chassis 5; the cam bracket 4 is riveted or The threaded connection mode is fixed in the case 5 and used with the upper cover lock to realize the relative movement between the case 5 and the case upper cover 3 .

[0034] The handle 1 is rotatably installed on the housing 3, the cam support 4 is matched with the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com