Nanometer flame-resistant wall cloth and preparation method thereof

A nano-flame retardant and wall covering technology, which is applied in the direction of flame retardant fibers, textiles, papermaking, and fiber treatment, can solve the problems of poor antibacterial effect and poor fireproof performance, and achieve improved antibacterial effect, flame retardant performance, and fire prevention. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

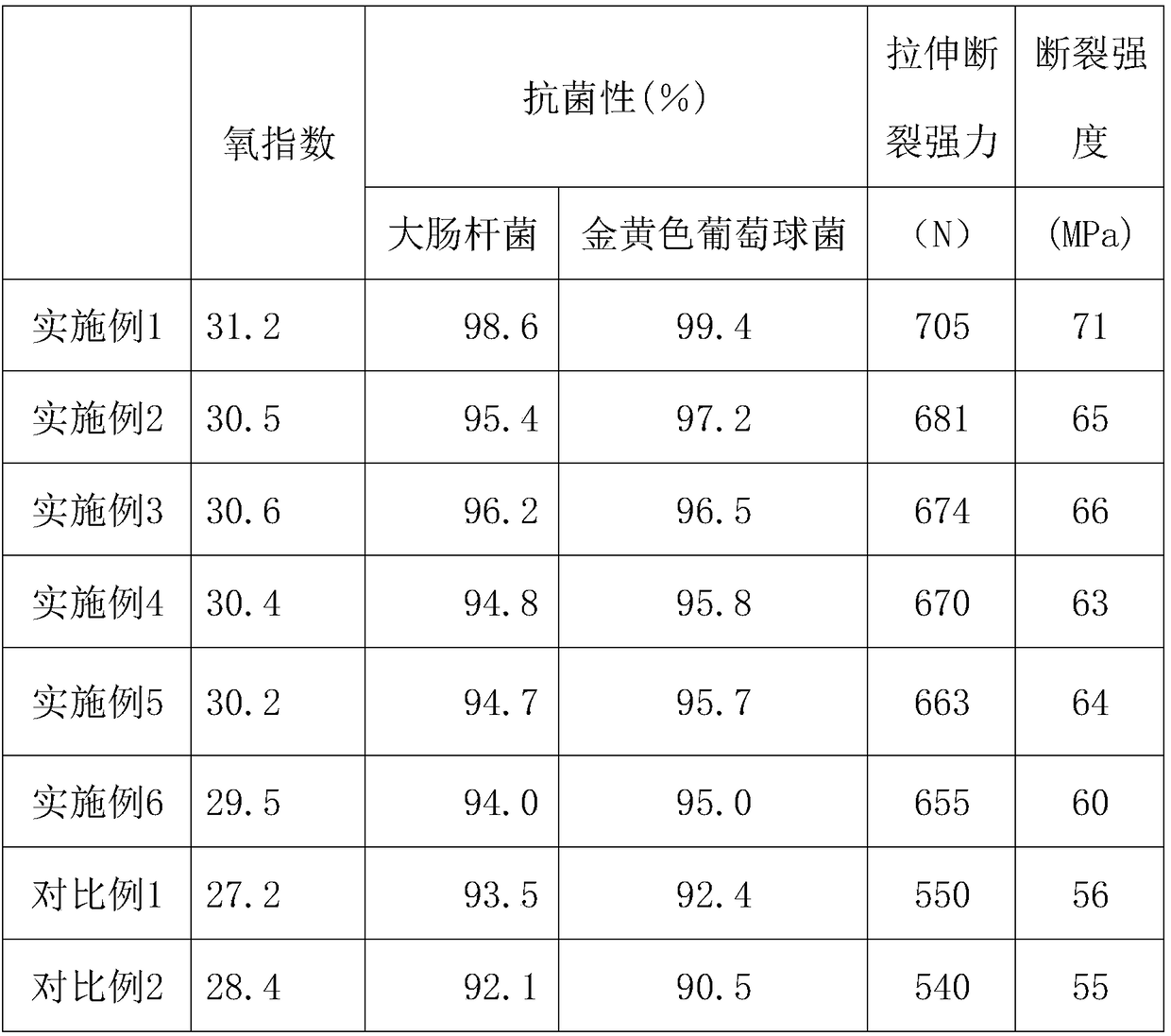

Examples

preparation example Construction

[0040] A preparation method of nano flame-retardant wall covering, comprising:

[0041] The preparation steps of the non-woven fabric base layer: mix the polyhexamethylene guanidine salt, surfactant, stabilizer, chelating agent and water in the formula amount evenly, then add the nano-silver in the formula amount, stir fully to complete the dispersion of the nano-silver, Obtain the antibacterial agent; then immerse the non-woven fabric base layer in the antibacterial agent for 50-100s, take it out, and dry it at a temperature of 65-75°C for 30-60 minutes to obtain the non-woven fabric base layer impregnated with the antibacterial agent;

[0042] The preparation step of flame retardant layer: mix the graphene of formula quantity, nano-aluminum hydroxide, nano-magnesium hydroxide, antimony trioxide, zinc borate, polyphosphate, dispersant, coupling agent, smoke suppressant, place Uniformly disperse in an ultrasonic instrument to obtain a flame retardant suspension; evenly spin co...

Embodiment 1

[0047] A nano-flame-retardant wall covering, comprising a non-woven fabric base layer, a flame-retardant layer, a pattern printing layer and an embossed layer are sequentially arranged on the decorative surface of the non-woven fabric base layer; an antibacterial agent is impregnated in the non-woven fabric base layer;

[0048] The flame-retardant layer is prepared from the following components in parts by weight: 4 parts of graphene, 8 parts of nano-aluminum hydroxide, 6 parts of nano-magnesium hydroxide, 8 parts of antimony trioxide, 6 parts of zinc borate, poly 7 parts of phosphate, 60 parts of dispersant, 1 part of smoke suppressant;

[0049] The antibacterial agent is prepared from the following components by weight: 1 part of nano silver, 35 parts of polyhexamethylene guanidine salt, 2 parts of surfactant, 1 part of stabilizer, 1 part of chelating agent and 60 parts of water share;

[0050] The smoke suppressant includes molybdenum trioxide, zinc aluminate and ammonium ...

Embodiment 2

[0057] A nano-flame-retardant wall covering, comprising a non-woven fabric base layer, a flame-retardant layer, a pattern printing layer and an embossed layer are sequentially arranged on the decorative surface of the non-woven fabric base layer; an antibacterial agent is impregnated in the non-woven fabric base layer;

[0058] The flame retardant layer is prepared from the following components by weight: 2 parts of graphene, 6 parts of nano-aluminum hydroxide, 6 parts of nano-magnesium hydroxide, 6 parts of antimony trioxide, 6 parts of zinc borate, poly 6 parts of phosphate, 66 parts of dispersant, 2 parts of smoke suppressant;

[0059] The antibacterial agent is prepared from the following components by weight: 3 parts of nano silver, 30 parts of polyhexamethylene guanidine salt, 1 part of surfactant, 2 parts of stabilizer, 2 parts of chelating agent and 62 parts of water share;

[0060] The smoke suppressant is molybdenum trioxide.

[0061] A preparation method of nano f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com