Anti-explosion spinning preheating furnace

A preheating furnace, explosion-proof technology, applied in textiles and papermaking, feeding solution to spinnerets, complete sets of equipment for the production of artificial threads, etc., can solve the problems of safety production accidents, simple structure, high pressure of heat pipes, etc. , to achieve the effect of improving operational stability, simple and effective structure, and improving explosion-proof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

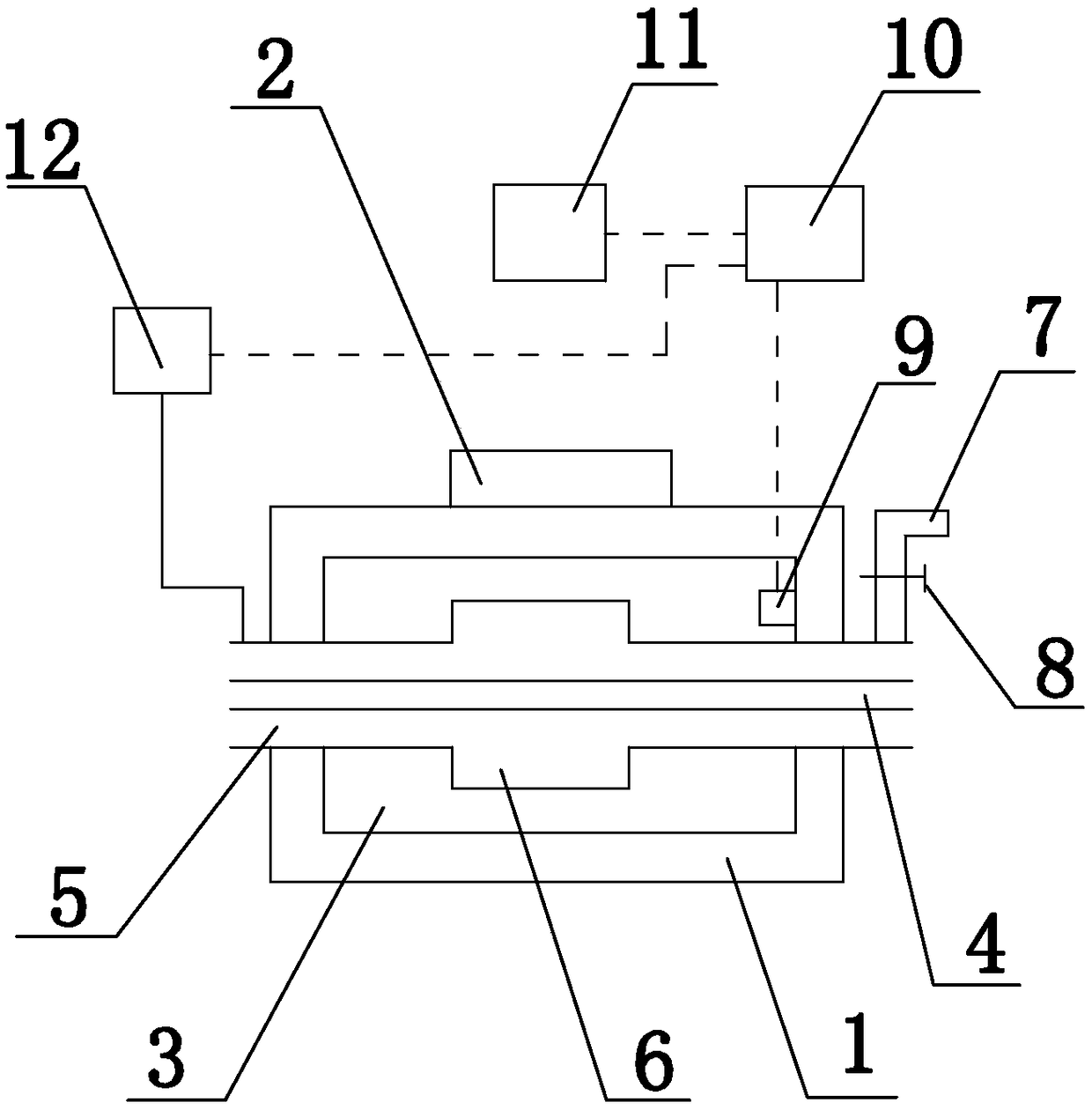

[0011] Such as figure 1 As shown, the explosion-proof spinning preheating furnace has a structure including a furnace body 1 with a furnace cover 2 on the top, an insulation layer on the inner wall of the furnace body 1, a heating chamber 3 inside the furnace body 1, a spinning tube 4 and a heat-conducting oil tube 5 Through the heating chamber 3, the spinning tube 4 and the heat conducting oil pipe 5 are concentrically arranged inside and outside, the heat conducting oil pipe 5 is externally connected to the heat conducting oil heating device 12, the heat conducting oil pipe 5 in the heating chamber 3 is provided with an expansion section 6, and the heat conducting oil pipe outside the heating chamber 3 is provided with A pressure relief pipe 7 is provided with a pressure relief valve 8 on the pressure relief pipe 7 .

[0012] The heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com