Easy-to-process high-modulus matte thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane and elastomer technology, applied in the field of matte thermoplastic polyurethane elastomer and its preparation, can solve the problems of reduced mechanical properties of materials, unsatisfactory matte effect, narrow processing window, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

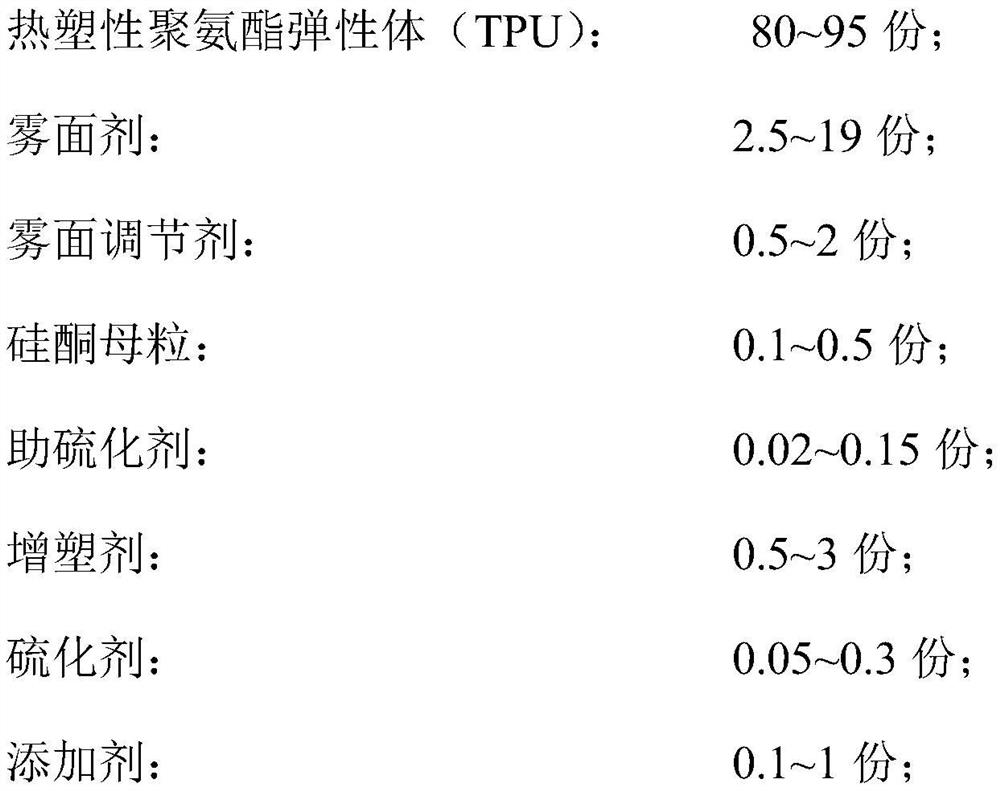

Method used

Image

Examples

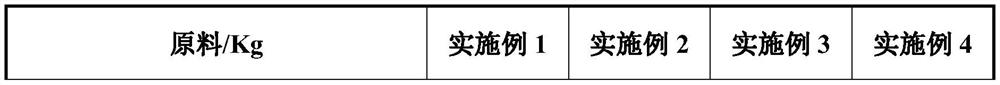

Embodiment 1

[0034] (1) Weigh the quality and dosage of raw materials listed in Example 1 in Table 1, add thermoplastic polyurethane, matte agent, matte regulator, silicone masterbatch, and auxiliary vulcanization agent into the twin-screw extruder through No. 1 feeding system In the extruder, the additives are added into the twin-screw extruder through the No. 2 feeding system, melted and extruded in the screw, and the thermoplastic polyurethane composition pellets are obtained after being pelletized and dried under water. The temperature of the screw is 200°C. The speed is 100RPM;

[0035] (2) Uniformly dissolving vulcanizing agent in plasticizer to obtain a mixed plasticizer solution containing vulcanizing agent, the mixed solution and the thermoplastic polyurethane composition particles prepared in step (1) are added to a low-speed mixer at the same time, at 60 Stir at ℃, the plasticizer is completely absorbed, and after drying, an easy-to-process, high-matte effect, high-modulus matte...

Embodiment 2

[0037] (1) Weigh the quality and dosage of raw materials listed in Example 2 in Table 1, add thermoplastic polyurethane, matte agent, matte regulator, silicone masterbatch, and co-vulcanizing agent into the twin-screw extruder through No. 1 feeding system In the extruder, the additives are added into the twin-screw extruder through the No. 2 feeding system, melted and extruded in the screw, and then pelletized and dried under water to obtain thermoplastic polyurethane composition particles. The temperature of the screw is 160°C. The speed is 80RPM;

[0038] (2) Uniformly dissolving vulcanizing agent in plasticizer to obtain a mixed plasticizer solution containing vulcanizing agent, the mixed solution and the thermoplastic polyurethane composition particles prepared in step (1) are added to a low-speed mixer at the same time, at 60 Stir at ℃, the plasticizer is completely absorbed, and after drying, an easy-to-process, high-matte effect, high-modulus matte thermoplastic polyure...

Embodiment 3

[0040] (1) Weigh the quality and dosage of raw materials listed in Example 3 in Table 1, add thermoplastic polyurethane, matte agent, matte regulator, silicone masterbatch, and auxiliary vulcanization agent into the twin-screw extruder through No. 1 feeding system In the extruder, the additives are added into the twin-screw extruder through the No. 2 feeding system, melted and extruded in the screw, and then pelletized and dried under water to obtain thermoplastic polyurethane composition particles. The temperature of the screw is 180°C. The speed is 50RPM;

[0041] (2) Uniformly dissolving vulcanizing agent in plasticizer to obtain a mixed plasticizer solution containing vulcanizing agent, the mixed solution and the thermoplastic polyurethane composition particles prepared in step (1) are added to a low-speed mixer at the same time, at 50 Stir at ℃, the plasticizer is completely absorbed, and after drying, an easy-to-process, high-matte effect, high-modulus matte thermoplasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com