Multi-rotor aircraft

A multi-rotor aircraft and rotor technology, applied in the field of aircraft, can solve the problems of unbalanced flight efficiency and aircraft size, reduced flight efficiency, increased load, etc., to increase load and flight time, improve flight efficiency, reduce The effect of footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

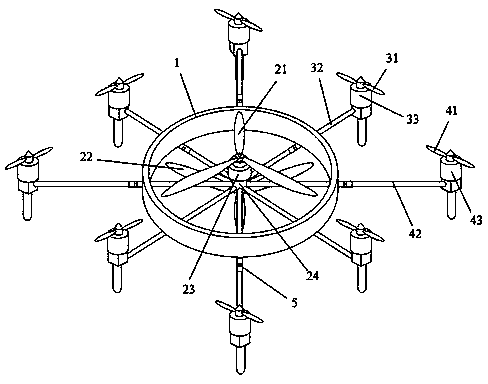

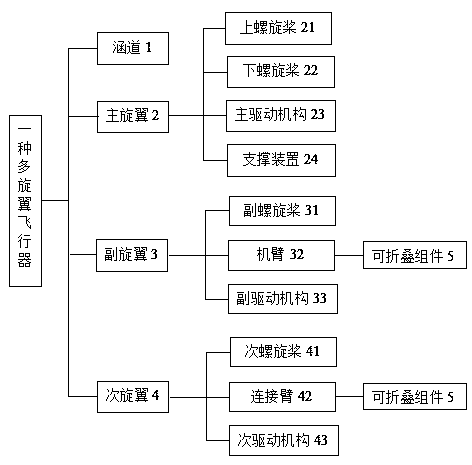

[0051] See attached figure 1 , the main rotor 2 is set inside the duct 1, the auxiliary rotor 3 and the secondary rotor 4 are located at the periphery of the duct 1, and the secondary rotor 4 is located at the periphery of the auxiliary rotor 3, the two are not on the same circumferential surface, so they are reduced to a certain extent The peripheral dimensions when the auxiliary propeller is unfolded, and the auxiliary propeller and the secondary propeller will not affect each other when they are in working condition at the same time; the main driving mechanism 23 of the main rotor 2 is a fuel engine, and the driving mechanisms of the auxiliary rotor 3 and the secondary rotor 4 are electric motors ,

[0052] That is, the main lift of the aircraft is provided by the main rotor 2 driven by the fuel engine, which can greatly increase the load and flight time of the aircraft; the auxiliary rotor 3 driven by the electric motor provides the attitude control moment of the aircraft,...

Embodiment 2

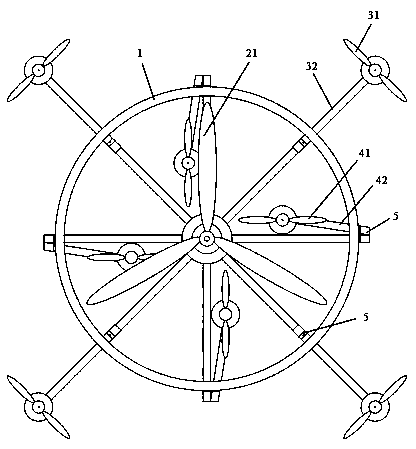

[0062] See attached figure 2 , the main rotor 2 is arranged inside the duct 1, and the auxiliary rotor 3 is located at the periphery of the duct 1; wherein the main driving mechanism 23 of the main rotor 2 is a fuel engine, and the auxiliary driving mechanism 33 of the auxiliary rotor 3 is an electric motor,

[0063] That is, the main lift of the aircraft is provided by the main rotor 2 driven by the fuel engine, which can greatly increase the load and flight time of the aircraft; the auxiliary rotor 3 driven by the electric motor provides the attitude control moment of the aircraft, controls the attitude of the aircraft, and assists the main rotor 2 Precisely adjust the lift. The lift of the aircraft is set to a coarse and fine two-level adjustment mechanism, which is conducive to improving the utilization rate of fuel and batteries, and is conducive to improving the accuracy of control.

[0064] The upper propeller 21 and the lower propeller 22 fixed to the top and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com