Rod and wire online head and tail shearing system

A rod and wire, head and tail technology, applied in the field of rod and wire online head and tail shearing system, can solve problems such as breaking and accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

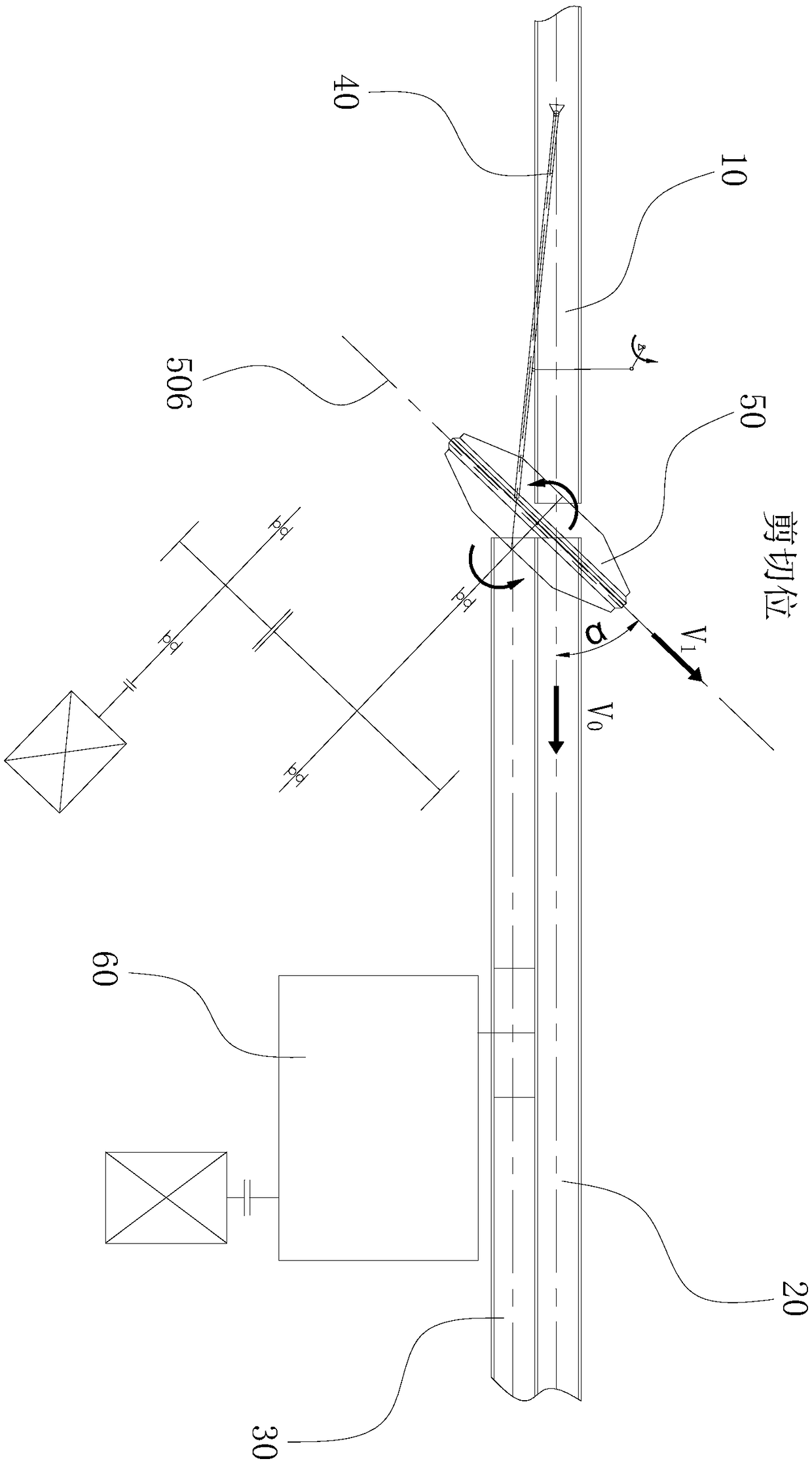

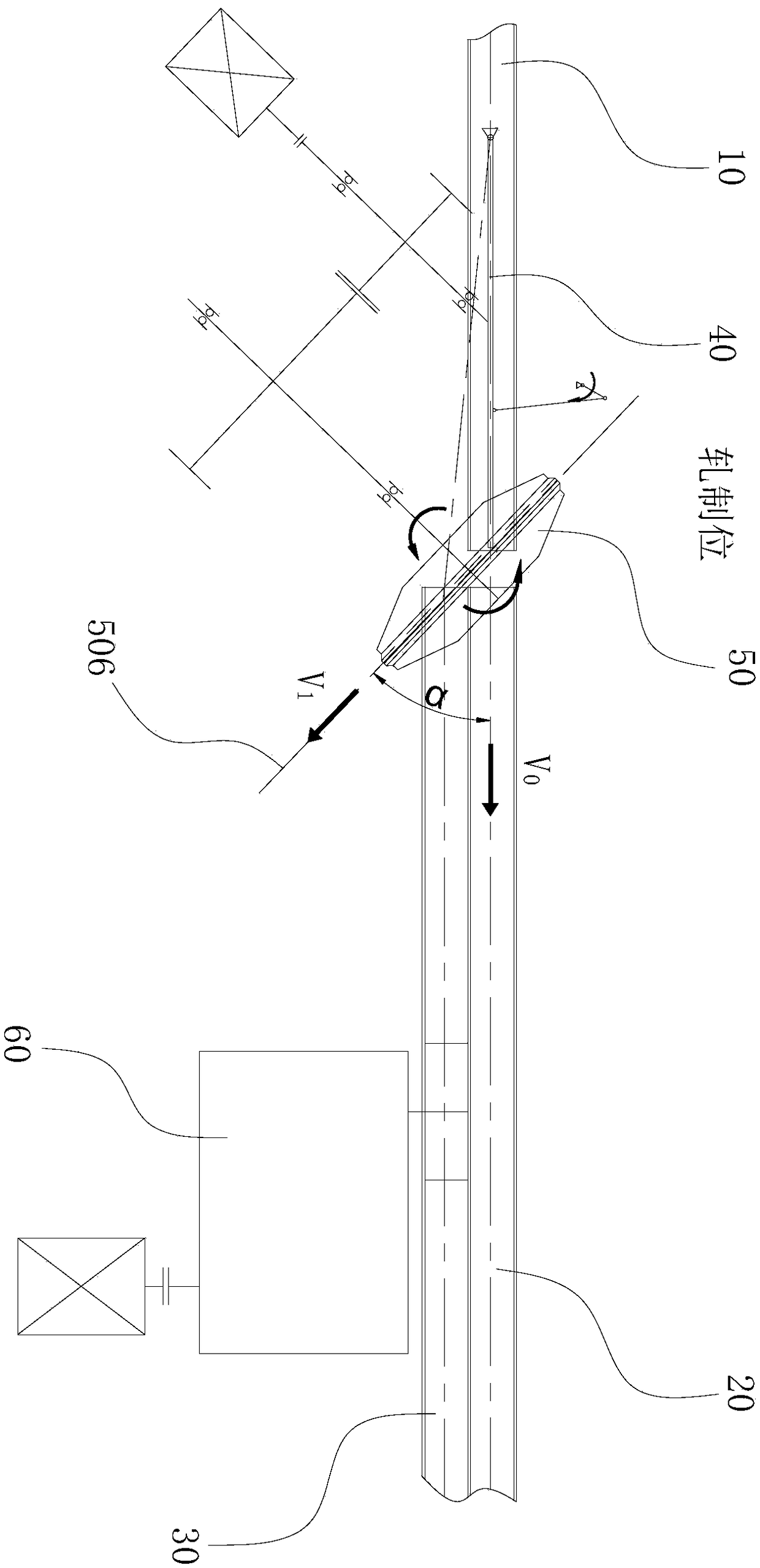

[0033] Such as Figure 1 to Figure 2As shown, the embodiment of the present invention provides an online head and tail shearing system for rods and wires, which mainly includes a front channel 10, a rolling channel 20, a shearing channel 30, a switch 40, a high-speed cutting shear 50 and a cutting head and tail fly Cut 60. The rolling channel 20 and the shearing channel 30 are arranged side by side in the horizontal direction, and the front channel 10 is arranged upstream of the rolling channel 20 and the shearing channel 30; the switch 40 is arranged on the front channel 10 and can be rolled The channel 20 and the shearing channel 30 swing back and forth to realize the channel changing function of the rod and wire between the rolling channel 20 and the shearing channel 30. The switch 40 can be driven by a servo motor, a servo cylinder or an electromagnetic induction device; The cutting shears 50 are arranged between the front passage 10 and the rolling passage 20 and the she...

Embodiment 2

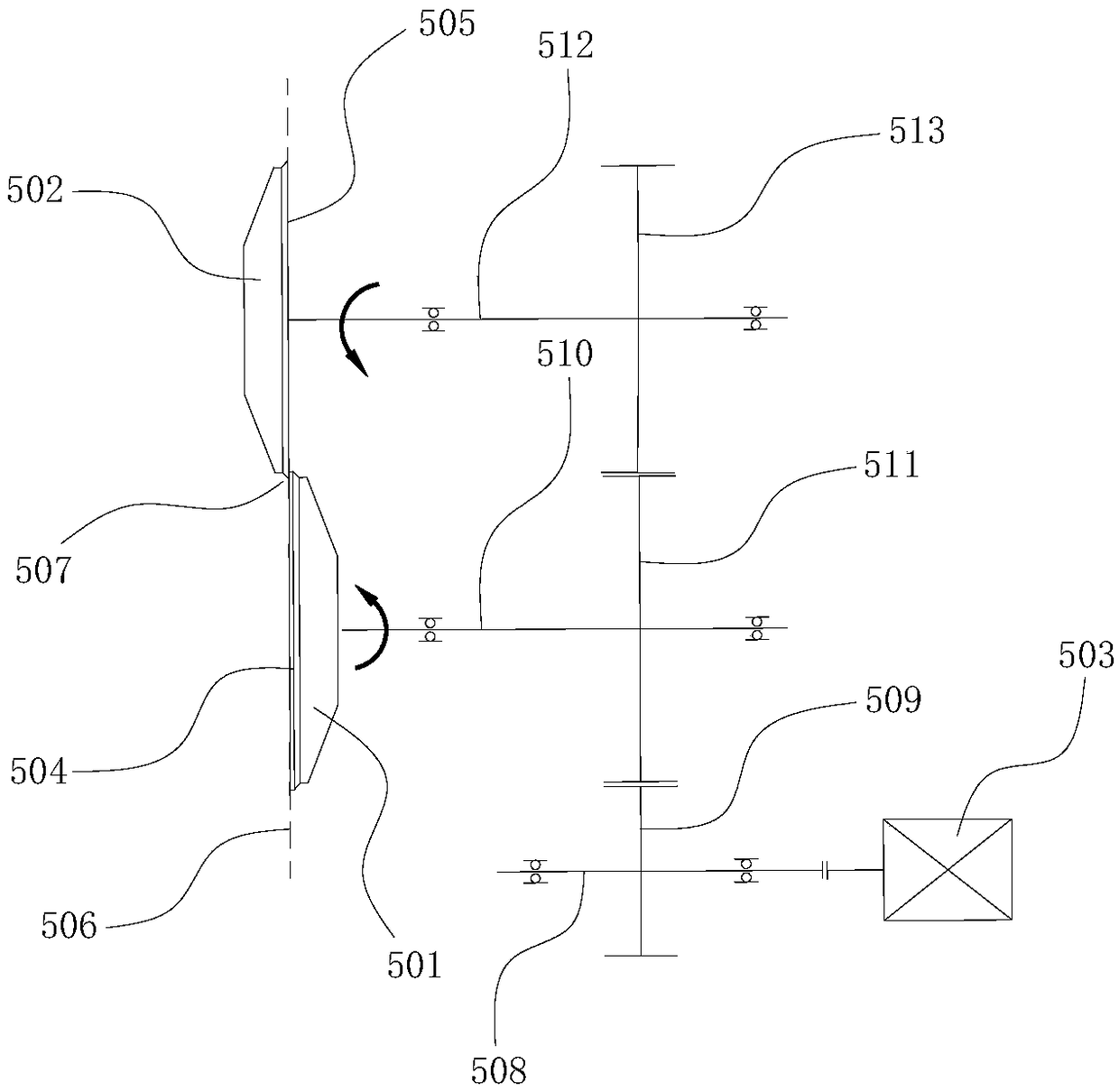

[0045] Such as Figure 5 to Figure 6 As shown, the only difference between this embodiment and Embodiment 1 is that the first synchronous gear 511 and the second synchronous gear 513 are respectively located on both sides of the shear plane 506, and there are two input gears 509, and the two input gears 509 Respectively recorded as the first input gear 509a and the second input gear 509b, the first synchronous gear 511 meshes with the first input gear 509a, and the second synchronous gear 513 and the second input gear 509b are simultaneously connected with the transmission between the two Gears 514 mesh. Based on this, the motor 503 first drives the first synchronous gear 511 and the transmission gear 514 to rotate in the same direction through the first input gear 509a and the second input gear 509b respectively, and the transmission gear 514 drives the second synchronous gear 513 to rotate in the opposite direction. Realize the opposite rotation of the first synchronous gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com