Anti-stress agent for relieving transportation stress of livestock before being slaughtered and preparation method of anti-stress agent

A transportation stress and anti-stress technology, applied in the field of livestock and poultry breeding, can solve problems such as damage to the liver of livestock, endanger human health, residues, etc., and achieve the effects of reducing pH value, increasing storage time, and reducing water loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

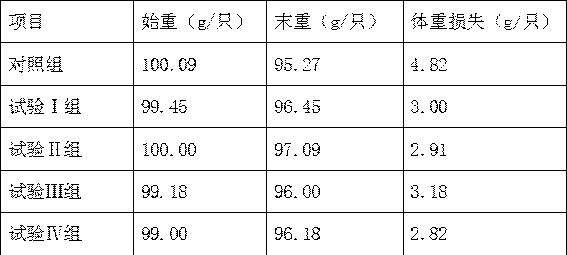

Examples

Embodiment 1

[0012] An anti-stress agent for alleviating the transport stress of livestock before slaughter and a preparation method thereof, the anti-stress agent contains 25% glucose, 20% guanidinoacetic acid, 20% gluten Aminoamide, 6% L-Lysine, 7% L-Ascorbic Acid, 7% Betaine, 2% Potassium Chloride, 3% Tannin, 2% Potassium Citrate, 3% Calcium Propionate, 1% Sodium Butyrate, 1% Sodium Diacetate, 2% Lactic Acid, 1% Neomethylhesperidin Dihydrochalcone.

[0013] The above-mentioned anti-stress agent for relieving the transport stress of livestock before slaughter is added to the drinking water of livestock according to the content of 1% by weight.

Embodiment 2

[0015] An anti-stress agent for alleviating the transportation stress of livestock before slaughter and a preparation method thereof, the anti-stress agent contains 35% glucose, 15% guanidinoacetic acid, 15% gluten Aminoamide, 7% L-Lysine, 6% L-Ascorbic Acid, 6% Betaine, 3% Potassium Chloride, 2% Tannin, 3% Potassium Citrate, 2% Calcium Propionate, 2% Sodium Butyrate, 2% Sodium Diacetate, 1% Lactic Acid, 1% Neomethylhesperidin Dihydrochalcone.

[0016] The above-mentioned anti-stress agent for relieving the transport stress of livestock before slaughter is added to the drinking water of livestock according to the content of 2% by weight.

Embodiment 3

[0018] An anti-stress agent for alleviating the transport stress of livestock before slaughter and a preparation method thereof, the anti-stress agent contains 40% glucose, 5% guanidinoacetic acid, 25% gluten Aminoamide, 2% L-Lysine, 10% L-Ascorbic Acid, 1% Betaine, 1% Potassium Chloride, 5% Tannin, 1% Potassium Citrate, 0% Calcium Propionate, 5% Sodium Butyrate, 0% Sodium Diacetate, 5% Lactic Acid, 0% Neomethylhesperidin Dihydrochalcone.

[0019] The above-mentioned anti-stress agent for relieving the transport stress of livestock before slaughter is added to the drinking water of livestock according to the content of 0.01% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com