Optical path system of laser radar, and laser radar

A technology of optical path system and laser radar, which is applied in the direction of radio wave measurement system, electromagnetic wave re-radiation, utilization of re-radiation, etc., can solve the problems of rotating structure wear, high cost, high processing precision requirements, etc., to achieve increased density, increased large area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The advantages of the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

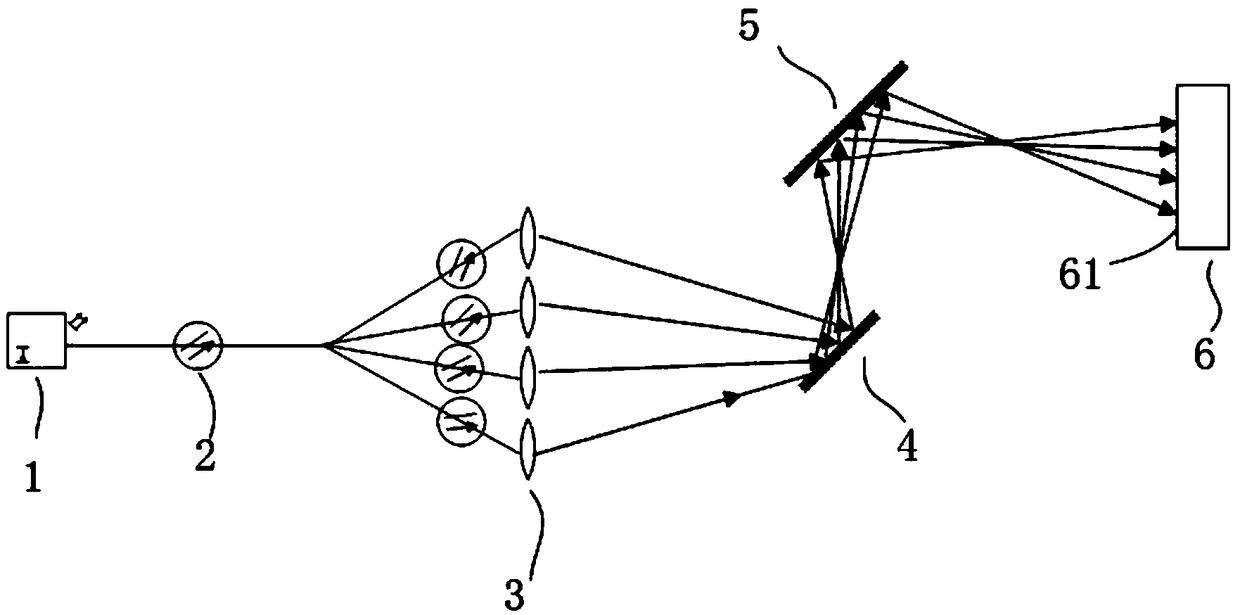

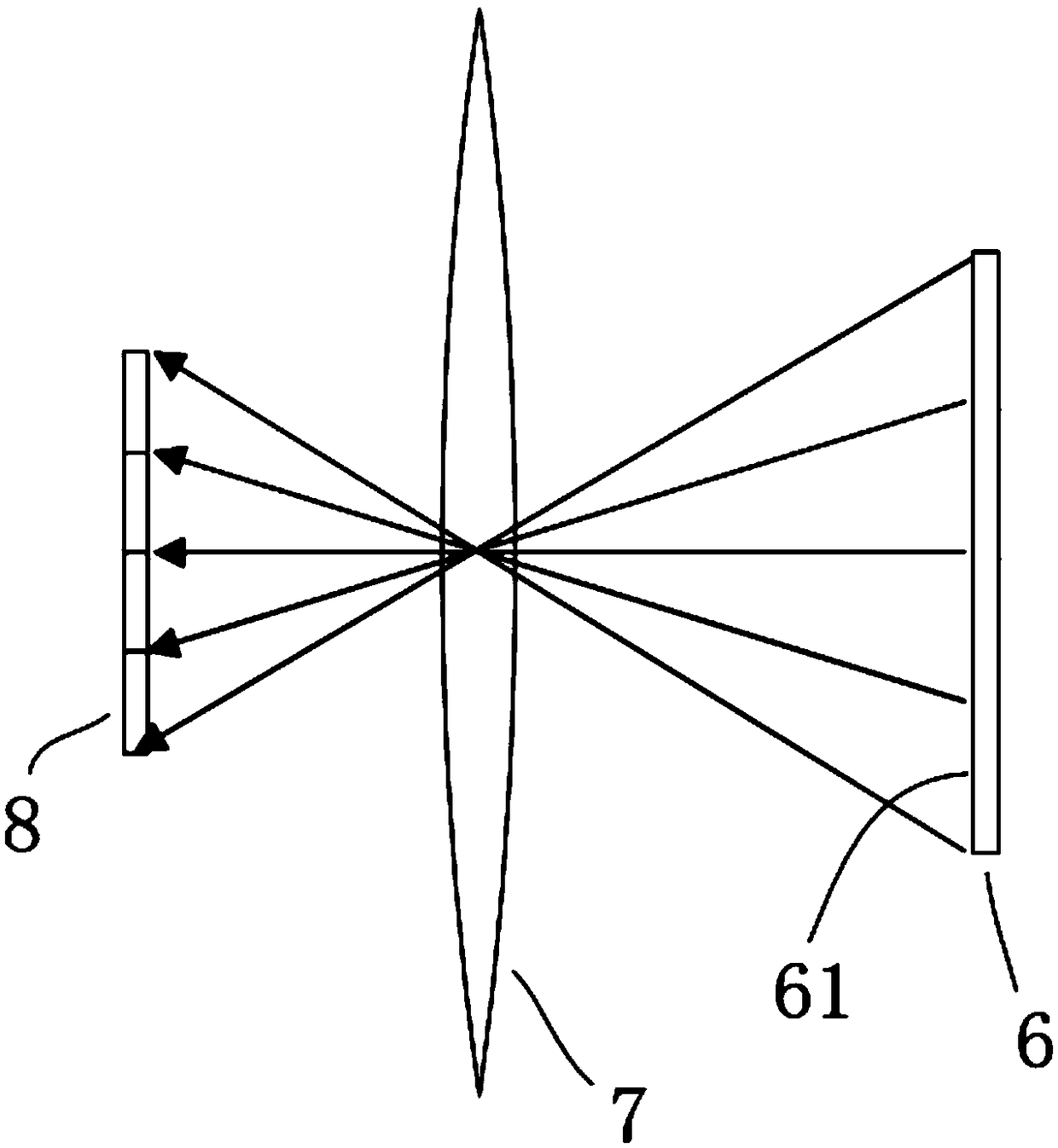

[0031] See attached figure 1 , attached figure 2 , is an optical path system of a laser radar, and the optical path system includes:

[0032] - Laser source 1 for emitting laser light. Preferably, the laser source 1 may be a solid-state laser or a semiconductor laser or a gas laser, and the solid-state laser may preferably be a fiber laser.

[0033] - An optical fiber 2, the optical fiber 2 is connected to the laser source 1, allows the laser to pass through, and divides the laser into no less than two laser beams. Preferably, the optical fiber 2 is provided with a laser beam splitter for splitting the laser light into multiple beams. The laser beam splitter is preferably a one-dimensional linear beam splitter.

[0034] - a collimator lens 3, the collimator lens 3 is arranged in the outgoing direction of the laser beam,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com